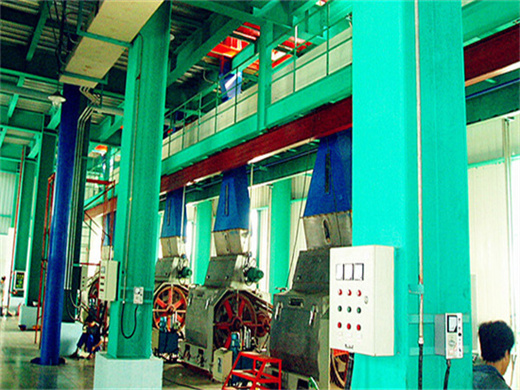

high efficiency peanut oil extraction equipment in johannesburg

- Usage: Peanut Oil

- Type: Oil Pressing Machine, Peanut empty bunch press

Production Capacity: 1tpd-30tpd - Voltage: Design according to customer demand

Power(W): 11 KW - Dimension(L*W*H): 4935*1523*2664

- Weight: Standard

Certification: ISO9001, BV, CE - Color: Design according to requirement

Production Material: Stainless steel or carbon steel - Raw material: Peanut

- Work principle: Mechanical extruding

- Warranty period: One year

English manual: Yes - Factory visiting: Yes

Steps such as seed preparation, oil pressing, oil extraction, and oil refinement must be expertly enjoined to produce the highest quality oil.Peanut oil contains high amounts of energy and fat-soluble vitamins (A, D, E, and K) and essential fatty acids. Get Price.

Abstract. As naturally sourced proteins, peanut proteins have garnered significant attention from the food industry, owing to their numerous advantages, such as easy extraction, non-pungency, and high bioavailability. Furthermore, peanut proteins are highly digestible in the gastrointestinal tract and boast a high net protein utilization rate.

Peanut Oil Processing Technology

- Usage: advanced oil expeller machine

- Production Capacity: according to the capacity

- Model Number: QIE Peanut oil machine

- Voltage: 220v,380v,440v

- Power(W): according to the capacity

- Dimension(L*W*H): 430*230*350

- Weight: 1050 KG

- Certification: CE,BV,ISO

- name: advanced oil expeller machine

- raw materials: fresh Peanut

- texture: stainless steel,carbon steel

- package: wooden case special for Peanut oil machine

- other materials: Peanut ,Peanut ,Peanut kernel, Peanut

- using popular area: Srillanka, Malaysia,Phillipine,Nigeria,America tropical area

- main business: South East Asia,Middle America,West Africa

- using life: more than 15 years

- Material: Stainless Steel 304

Abstract. This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses.

High oil output rate. The oil yield of a groundnut oil extractor can reach about 50%. The dry cake residue rate is less than or equal to 8%. High efficiency. Our peanut oil expeller can process 500 kg of raw materials per hour. And only one person can operate the machine. Wide range of applications.

An Overview of Groundnut Oil Extraction Technologies - ResearchGate

- Usage: Peanut oil machines sri lanka

- Type: Peanut oil machines sri lanka

Production Capacity: 1-50t/d - Voltage: 380V/415v

Power(W): 15-50KW - Dimension(L*W*H): 1200*400*900mm3

Certification: ISO9001/BV/CE - Use: Used for extracting the oil from the vegetable seed

Moisture: 3% - deodorizaiton time: about 30min

- apply: for many materials

residual oil in cake: 1% - decoloring time: 15-20min

- original: china

capacity: 1-600t/d - Model: Peanut oil machines sri lanka

Groundnut oil extraction involves removing oil content of the groundnut seed. Study conducted in Northern Nigeria revealed that 75% of the rural women engaged in groundnut oil extraction used the.

Peanut oil extraction. Oil is crushed from cooked, dried peanut material in a screw press or oil expeller, which uses the mechanical force of a revolving barrel to squeeze the oil from the solid meal. Peanut’s high oil content requires double pressing to obtain maximum oil yields since the meal may still contain up to 14-20% residual oils.

Extraction Equipment | Oil Extraction | Distillique

- Usage: Peanut Oil

- Type: Cold & Hot Pressing Machine, crude cooking oil refinery plant

- Production Capacity: 10-5000T/D

- Model Number: DT-10030

- Voltage: 220V/380V/415V

- Power: 2.2KW

- Dimension(L*W*H): 1910*550*765 mm

- Weight: 420 KG

- Certification: ISO9001

- Raw material: Peanut

- Function: Vegetable Oil

- crude cooking oil refinery plant: Peanut, Cotton, Peanut,etc

Distillation is followed by Separation in order to separate the Oil from the Hydrosol. Soxhlet Extraction is used to extract the purified Essence (sometimes called The Pure) of a Botanical - it is a more time-consuming process, also with two stages, and it always uses a Solvent to do the Extraction. The actual Soxhlet Extraction is followed by.

The 6YL-100A peanut oil extraction machine is a highly efficient and versatile machine for oil extraction. Its outstanding features, including high oil extraction rate, simple structure, ease of operation, and durability, make it an ideal machine for small-scale oil extraction plants and farmers who wish to process their own oil.

BEST Price Peanut Oil Extraction Machine for High Efficient Oil Mill

- Usage: Peanut Oil

- Type: Vegetable Seed Oil Machine

- Production Capacity: 100%

- Model Number: 3000tons

- Voltage: 220/380V

- Power(W): 25-44kw

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Certification: CE ISO

- Type of oil extraction equipment: extraction machine

- Material: Stainless Steel SS304/316

- Advantage of oil extraction machines: Peanut ,Peanut ,Peanut

- Capacity: 10-3000t/d

- Feature of oil extraction machines: Multifunction High Efficient

- Function of oil extraction machines: Produce High

- Character: Screw Oil Pressing Machines

- Quality of oil extraction machines: Stable Quliaty

- Supplier Type: Manufacturer

- oil grade of oil extraction machines: first grade

The YZS series peanut oil extraction machine is well designed to meet the all the production capacity for best oil output. () It is mainly composed of feeder, pressing cage, gear box, screw axis and more. The feeding system includes feeder, feeder flange, etc. The pressing cage includes upper and lower pressing cages, roll bar, pressing rings.

Groundnut is a very common oil bearing material, so the technology of extracting peanut oil is relatively mature. Hongde GROUP is the largest groundnut oil extraction machine manufacturer and supplier in India. We are focused on providing the most advanced oil processing machines to help our customers reduce costs and improve oil production.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What is peanut pretreatment technology?

- Pretreatment Technology Peanut pretreatment refers to a series of treatment processes before oil production, such as cleaning, shelling, grading and selection, drying, cooling, thermal conditioning, pressing, and cooking.

- How does a peanut halving machine work?

- Then, the dried peanut kernels are rapidly fed into the kernel-halving machine to peel the red skin, and then transported to the color sorting machine by a conveyor so as to effectively remove the yellow-spotted, moldy, worm-eaten, or incompletely peeled peanuts.

- Voltage: 380V/415v

- Voltage: Design according to customer demand