fully peanut oil solvent extraction machine in malawi

- Usage: for oilseeds and Peanut oil

- Type: Cold & Hot Pressing Machine

Production Capacity: 20-2000T/day - Voltage: 380V

Power(W): 15KW - Dimension(L*W*H): standard

- Weight: 30tons

Certification: CE,ISO - Equipment Name: 1T-500TPD Peanut oil refinery

Machinery type: Large-scale and small-scale - Raw material: Peanut

- Application: Oil Production Line

Advantage: High Efficient - Color: Silver

- Function: Cold Press

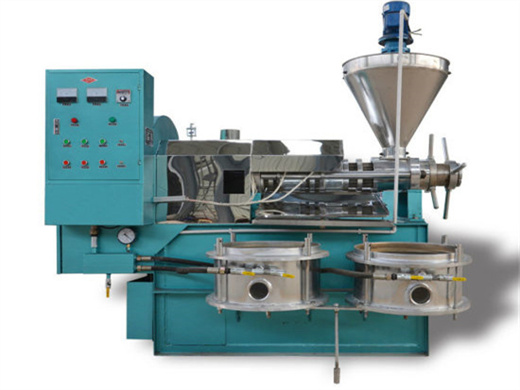

Model: HT-2 - Item: Industrial Manual Oil Extractor

Groundnut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into.

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

Peanut / Groundnut Oil Extraction Machine Manufacturers and

- Usage: vegetable oil processing plant

- Type: Oil Pressing Machine

Production Capacity: 400~600kg/h - Voltage: 220V/380V

Power(W): 18.5kw - Dimension(L*W*H): 1500*1600*2500mm

- Weight: 2000kg

Certification: ISO9001 - Keywords: vegetable oil processing plant

Raw material: Peanut - Advantage: Energy Saving

- Machine Material: Part of are stainless steel

Warranty: 1year - Residual: Less than5%

- Supplier strength: with 30 years experiences

Machine color: According customer needs - Product name: vegetable oil processing plant

- Business type: manufactory

Groundnut is a very common oil bearing material, so the technology of extracting peanut oil is relatively mature. Hongde GROUP is the largest groundnut oil extraction machine manufacturer and supplier in India. We are focused on providing the most advanced oil processing machines to help our customers reduce costs and improve oil production.

There are three types of peanut oil extraction machines using this methods, including. Small Peanut Oil Press Machine. Large Oil Press for Groundnut Oil. Hydrualic Oil Press for Cold Peanut Oil. Large Screw Oil Press Machine - suitable for large scale peanut oil manufacturing plant and the pre-pressing sector of solvent extraction plant.

Processes | Free Full-Text | Defatting and Defatted Peanuts

- Usage: Peanut oil

- Type: Cold Pressing Machine

- Voltage: 380v

- Dimension(L*W*H): 1400*1300*2300mm

- Weight: 1400 KG

- Warranty: 2 years

- Warranty of core components: 2 years

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other

- Oil type: Peanut Oil

- Name: Oil Pressing Machine/Hydraulic oil press machine

- Machine Material: High strength rigid

- Function: Press Oil Seeds

- Raw material: Peanut/hemp/avocado/mustar

- Advantage: Energy Saving & Simple Operation

- Package: Steel cage export

- Delivery time: 7 Days

- Machine color: white

- Quality: High Level

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: India

- Certification: S.G.S/CE

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated.

The solvent extraction plant is designed to extract oil directly from oil seeds containing less than 20% oil, like soybeans, after flaking. Or it extracts oils from pre-pressed or fully pressed cake of seeds containing more than 20% oil like sunflowers, peanuts, cotton seed, palm kernels, canola, copra, castor and a variety of other materials.

Peanuts Solvent Extraction Plant - Oil Mill Machinery

- Industrial Use: Food

- Use: Sandwich, cake, Bread, Snack, Chocolate, Noodle, Pizza, Peanut OIL, Salad, Other Food

- Material: EVA/PE, PE/EVA/EVA/EVA/PE

- Type: Vacuum Bag

- Usage: Food Snacks Packaging, Food Snacks Packaging

- Feature: Moisture Proof, Barrier

- Hardness: Soft

- Processing Type: Blow Molding

- Transparency: Transparent

- Model Number: VB013

- Bag Type: Vacuum Bag

- Sealing & Handle: Heat Seal

- Surface Handling: Hot Stamping

- Material Structure: EVA/PE, PE/EVA/EVA/EVA/PE

- Advantage: PVDC High Barrier

- Product name: Plastic shrink bag

- Custom Order: Accept

- Sample: Free

The solvent extraction method recovers almost all the oils and leaves behind only 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant etc. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%.

- Oil extractor: using solvent N-hexane to extract oil from pressed oil cake - Mixed oil/wet meal : after oil extractor, will get mixed oil with solvent and wet meal with solvent - Three evaporation: using three muti-effective evaporators to transform solvent to gas which will be cooled down and collected by passing condensers.

Introduction of Peanut Oil Extraction

- Usage: green tea extract plant extract

- Type: green tea extract plant extract

Production Capacity: 50-300TPD - Voltage: 380V/50HZ

Power(W): according to capacity - Dimension(L*W*H): 1200*400*900mm3

Certification: ISO CE BV - Name: green tea extract plant extract

Warranty: 1 year - Application: oil extracted

- Residual oil in meal: less than 1%

Power consumption: not more than 15KWh/T - Solvent consumption: less than 2kg/t

- Crude oil moisture and volatile matter: ≤ 0.30%

Finished meal moisture: ≤ 13% (adjustable) - Residual solvent in finished meal: ≤300PPM (qualified detonated experiment)

- Steam consumption: ≤ 280KG/T (0.8MPa)

1. Clean and dry of peanut: peanut unavoidably with some impurities.If you don't clear peanut kernels in the midst of the earth and stem leaf of sundry, they not only affect the quality of oil and cake, and will be part of the adsorption grease, reduce the yield efficiency.If the catsup with sand, metal, hemp rope and other sundry, more will cause wear parts, etc., induce production accident.

The oil extractor has a widely usage and perfect oil pressing effect. It can make peanut oil, groundnut oil, sunflower seed oil, sesame seed oil etc grain oils. Pressed oil light color, nutrient-rich, little damage to the protein, is conducive to the full utilization of oil protein. ·MOQ:set. ·Supply Ability: 200 sets per month.

- What is peanut oil processing technology?

- This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What is the method of extraction of peanut oil?

- Always method used depends on the oil. Peanuts / Groundnut oils are often extracted using a solvent like hexane, while aromatic oils are extracted with various methods including steam distillation and the traditional cold pressing method.

- How to make peanut oil in China?

- Currently, there are two pressing methods: high-temperature pressing and cold pressing. More than 90% of oil production in China adopts the traditional technique of high-temperature pressing, and the peanut oil produced with this method has a strong fragrant flavor and is therefore greatly favored by consumers.

- Voltage: 380V/50HZ

- Voltage: 220V/380V

- Voltage: 380V