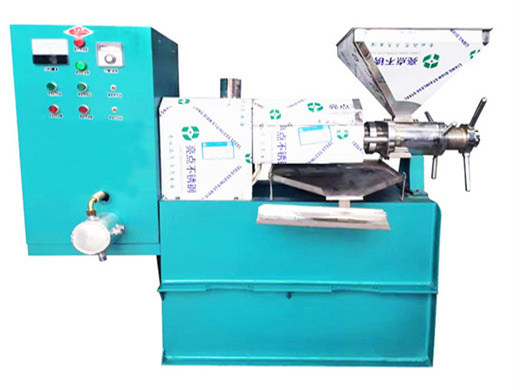

fruit pulp and coconut oil processing machine in togo

- Usage: Coconut Oil

- Type: Oil Extraction Machine

- Production Capacity: 150-300kg/h

- Voltage: 220v/380v/Customer request

- Dimension(L*W*H): 1900*1400*1700mm

- Weight: 1100 KG

- Core Components: Motor

- Oil type: Coconut Oil

- Name: Coconut oil expeller machine

- Raw material: Coconut Coconut

- Function: Oil Pressing

- Operation: Automatic Operate

- Advantage: Energy Saving Low Residual

- Oil rate: Meal Residual: 1%

- Capacity: Large

- Material: Stainess Steel

- Processing Types: Screw Pressing

- Keep working: 24 Hours

Coconut oil is produced by cold-pressing from virgin coconut or dried coconut pulp. The oil has a low melting point of about 24 degrees, and in a cool place becomes almost dense solid. A distinctive feature of unrefined coconut oil is its aroma - the smell of fresh coconut without impurities of other odors. Coconut Oil Benefits

Boost the utilization of your facility. Reduce waste. Diversify your streams of income. JBT citrus processing machinery lets you use everything from the peels to the pips to the pulps. Instead of relying on just the juices, you can develop lucrative secondary and tertiary products like essential oils and cattle feed.

Coconut Food Production | Coconut Handbook

- Weight: 12400 kg

- Core Components: OtherProduct name: Soft Ice Cream Machine Commercial

- Function: Automatic Making Ice Cream

- Usage: Food Industry Equipment

The Codex Standards for Aqueous coconut products states that coconut milk should contain at least 10% fat, 2.7% non-fat solids, and 12.7-25.3% total solids. While coconut cream should contain at least 20% fat, 5.4% non-fat solids and 25.4-37.3% fat (Table 6.1). Table 6.1. Classification of coconut milk and cream.

The production steps and technology to process fruit pulp depend on the fruit type, scale of production, and desired end product. Typically fruits, such as grapes, are first washed, sorted, and inspected. Afterward, they are peeled and chopped or cut into pieces. Finally, the pulp or fruit juice is extracted, sieved, beat via rotation, and.

Engineering an Improved Coconut Processing System in the

- Usage: Coconut Oil

- Type: small scale edible oil refining machine, small scale crude Coconut oil refinery

- Production Capacity: 1TPD-20TPD

- Model Number: 6YY-260

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Certification: ISO9001-2008

- Color: Silver or others

- Production Material: Carbon steel, stainless steel

- Raw material: Coconut

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical principle

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

The Wijose Process of coconut processing developed for the production of copra, milk and dietary flour resulted to 94.7% recovery of the coconut fruit parts and waste materials.

Specifically designed for coconut processing from dehusking to coconut oil extracting, coconut husk processing and coconut shell processing. We have exported and installed our coconut machines in countries such as Indonesia, Nigeria, Ghana, Papua New Guinea, Fiji, Tahiti, Bahamas, Dominican Republic, Guyana, Ecuador and Mexico. Ask Us.

Tropical fruit pulp: processing, process ... - ResearchGate

- Usage: Coconut,beans,Coconut etc, Coconut nuts Coconut

- Type: Cold & Hot Pressing Machine, Cold pressing and hot pressing

- Production Capacity: 50%-55%

- Voltage: 220-380v/50-60hz

- Power: 4000w

- Dimension(L*W*H): 145*95*125cm

- Weight: 420KG

- Certification: CE

- Keep working: 12 hours

- Material: Stainless steel

- Control mode: full automatic

- Advantage: Easy use,energy saving,simple

- Packaging Detail: Wooden case

- Filter: 2 pcs

- Working Life: 6-8 years

- Input(raw material ): 70-90kg/h

Fruit pulp is the most basic food product obtained from fresh fruit processing. Fruit pulps can be cold stored for long periods of time, but they also can be used to fabricate juices, ice creams.

The Coconut oil was finally separated from the curd via decantation. The Coconut curd, which is also called Coconut pulp, was de-oiled using soxhlet apparatus, with n-hexane as a separating solvent and the solvent-free De-oiled coconut pulp was dried at 318.15 K until a constant weight was attained, sieved with a 250 μm sieve to uniform size. 2.2

What Is Fruit Pulp? The Fruit Pulp Manufacturing Process

- Usage: Oil solvent extraction

- Type: Oil solvent extraction

Production Capacity: 100% - Voltage: 220V/380V/440V

Power(W): According to the capacity - Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

Certification: ISO9001 - Item: Small Coconut Oil Extraction Equipment

Material: Stainless Steel 304 - Function: Oil solvent extraction

- Advantage: Energy Saving

- Feature: High output

- Performance: Excellent

Color: as your requirement - Application: Coconut,etc.

- Turnkey Project: Yes

Each type of fruit pulp brings its own flavor and texture to whatever dish it’s used in. Fruit pulps add personality and distinction to all sorts of dishes—making them an invaluable ingredient in the food and beverage industry. The Fruit Pulp Manufacturing Process. The fruit pulp manufacturing process typically involves the following steps: 1.

Students Collaborate with Co-Op. As designed, the machine is powered by a 120-V AC motor that rotates a milled grinder against a stationary mesh to grind the fruit pulp into powder and separate it from seeds and fibers. It can process about 100 kg per day of the fruit, which is high in many vitamins and is in demand in Europe as an ingredient.

- What are the different types of coconut oil processing methods?

- Coconut oil processing methods or technologies are classified into two major types based on copra or fresh coconut kernel used. The oil extraction technology, which starts with copra as the raw material, is commonly known as the dry process.

- What is the wijose process of coconut processing?

- The Wijose Process of coconut processing developed for the production of copra, milk and dietary flour resulted to 94.7% recovery of the coconut fruit parts and waste materials. Seven mathematical models were examined to describe the drying behavior of coconut meat slices at 60, 70 and 80 o C.

- How a coconut kernel is converted into copra?

- Coconut kernel is converted into copra before it is expelled and refined for oil production. This is done by first drying the kernel under the sun in an oil mill. To extract coconut oil for extensive food and industrial purposes, dry processing is used.

- What is a coconut processing plant?

- A coconut processing plant was developed based on the conceptual design of the Wijose Process. Content may be subject to copyright. … Figure 3 shows the laboratory scale of a cabinet dryer for drying coconut kernels.

- Voltage: 220V/380V/440V