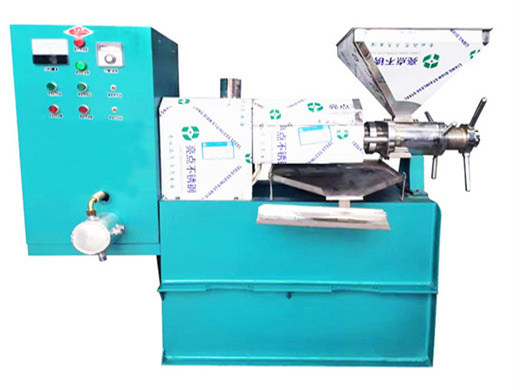

european standard coconut oil packing machine in nepal

- Usage: mainly used to extract Coconut oil

- Type: Coconut fruit oil press machine

- Production Capacity: 100kg/h

- Voltage: 380V

- Dimension(L*W*H): various with capacity

- Weight: depends on

- Core Components: Motor, Pump, Engine, Coconut fruit oil press machine

- Machine type: Coconut fruit oil press machine

- Product: to make crude Coconut oil, red Coconut oil or refined Coconut oil

- Capacity: 300-500kg/h

- Material of equipment: stainless steel and carbon steel

- Raw material: Coconut fruit

- Certification: CE and ISO, CE and ISO

- Oil residual: less than 7%

- Manufacturing experience: 20 years experience in edible oil field

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: Nigeria

Packaging is essential for keeping food products safe for consumption. It primarily aims to contain the liquid product, prevent leakage and protect the contents from physical, chemical and biological hazards, which are present throughout the product’s shelf life. In the case of coconut liquid products, the choice of packaging is important in.

Figure 1. Examples of bulk packaging for virgin coconut oil: Consumer packaging The recommended packaging material for virgin coconut oil is glass or high-density polyethylene, ranging from around 200 ml to 2 litre. Figure 2. Examples of consumer packaging for virgin coconut oil: 2. Which European markets o?er opportunities for exporters of

Unveiling the Intricacies of Coconut Oil Packaging Machine

- Usage: seeds oil press

- Type: Oil Extraction Machine

- Production Capacity: 200kg/h-2000kg/h

- Voltage: 380v

- Dimension(L*W*H): 2100*780*1600mm

- Weight: 700 KG, 700kg

- Core Components: Gear, Engine

- Oil type: Coconut Oil

- Product name: oil press machine with filter

- Raw material: A variety of oil seeds

- Model: 6YL-95A

- Material: Stainess Steel

- Productivity: 200kg/h

- Advantage: Easy installation, automatic

- Application range: Coconut.etc

- Squeezer speed: 35-39r/min

- Keywords: oil press machine with filter

Introduction. In the realm of efficient coconut oil packaging, a remarkable invention takes center stage—the coconut oil packing machines. These ingeniously designed apparatuses serve the purpose of streamlining the process of encapsulating coconut oil into a myriad of formats, ranging from bottles, pouches, and jars, to containers of diverse shapes and sizes.

The OLAF (Oil, Liquids And Fats) is the perfect high quality oil and fat filling solution for all (semi-)liquids. The automatic oil packaging machine OLAF has many useful features. To start, the machine is efficient, hygienic and accurate. The machine is also one of a kind when it comes to design. In addition the machine can be used to fill.

Coconut Oil Filling And Packaging Machine | Edible Oil

- Usage: cooking oil

- Type: cooking oil

Production Capacity: 20-2000T/day - Voltage: 380V

Power(W): Standard - Dimension(L*W*H): Standard

- Weight: Standard

Certification: CE,ISO - Commodity: Cooking Oil Manufacturing Machine

Area Needed: According to the capapcity Filling machine Features. 1, Compact structured, good-looking, easy to operate and highly automated. 2, Parts with contact with material are all made of stainless steel of food-grade, no dead angles and easy to clean up. 3, Filling volume is controlled with film valves to ensure accurate filling.

Coconut in Food Products. Coconut oil is widely added to packaged foodstuffs and also stands alone, marketed as a 100% pure, organic, and/or fair trade product. It is consumed as a food supplement, added to smoothies, hot beverages, and baked goods. The oil is also used for frying and general stovetop applications.

Edible Oil Packaging Solutions | Bag In Box & Pouches - Liquibox

- Usage: canola oil cold pressed

- Type: whole canola oil cold pressed

Production Capacity: 100% - Voltage: 380V

Power(W): according to capacity - Dimension(L*W*H): various with capacity

- Weight: changed with capacity

Certification: CE and ISO - Raw material: Coconut

- Solvent name: n-hexane

- Capacity: from 5T to 2000T canola oil cold pressed

Oil content in Coconut: from 18-22% - Oil residues: less than 1%

- Function: getting canola oil and refining it

Manufacturing experience: 19 years experience in edible oil field - Material of equipment: stainless steel and carbon steel

Bag-in-box and pouch flexible packaging is designed to reduce product waste, improve efficiency in dispensing and preserve oil quality. Learn more about the advantages of flexible packaging on our benefits page. Preserve the flavor and quality of your edible oil, from the grove to the kitchen. Use our durable bag-in-box and pouches for edible oil.

VKPAK designs and builds filling machines and packaging equipment for coconut oil. This coconut oil bottle filling machine is suitable for filling liquor, juice, liquid seasoning, pesticide and other liquids, gravity transport, multiple filling heads can be filled at the same time. The height and spacing of the filling mouth can be adjusted.

Oil Pouch Packing Machine - Coconut Oil Packing Machine

- Usage: for all kinds of seeds

- Type: Oil Press Machine

- Production Capacity: 5t/24h

- Voltage: 380v

- Dimension(L*W*H): 1480*630*1570mm

- Weight: 700 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Coconut Oil

- machine name: oil mill machine

- Screw diameter: 100mm

- package: standard wooden case

- automatic extent: full-automatic

- warranty period: 1year

- efficiency: high

- consumption: 5.5

- material: stainless steel

- warranty: one year

Dimension. 1500 x 1500 x 2200mm. Range. 100-1000MI. Speed. 15-50 fills/min depends on Model. "IPK-ALL PACK" Automatic FFS Machine for Oil Packing. Model: IPK-306. IPK 306, Automatic Liquid VFFS Machine with clutch and break ( Servo) dragging system (linear motion bottom Jaw sealing), PLC Control Unit with Camera Trackeing sensor, Mech. coding.

- What type of packaging system is used for coconut liquid products?

- Different packaging systems are used for packaging coconut beverages, milk and cream. For pasteurized and extended shelf life coconut liquid products, non-aseptic packaging material and systems are preferred. In the case of long life coconut liquid products, aseptic packaging is essential.

- How are coconut liquid products packaged?

- Cans are then necked in and flanged in a special machine, covered with two coats of lacquer sprayed onto the internal surface of the can. Innovative packaging designs can help products stand out on the shelves. Typically, coconut liquid products can be packaged in five different carton formats.

- How to choose the best packaging material for coconut liquid products?

- In the case of coconut liquid products, the choice of packaging is important in ensuring product quality and use. The most suitable packaging material should only be chosen after careful consideration of the desired shelf life and end condition of the coconut liquid product.

- Why is packaging important for coconut liquid products?

- It primarily aims to contain the liquid product, prevent leakage and protect the contents from physical, chemical and biological hazards, which are present throughout the product’s shelf life. In the case of coconut liquid products, the choice of packaging is important in ensuring product quality and use.

- Voltage: 380V

- Voltage: 380V