eritrea sunflower oil extraction production plant in lagos

- Usage: Sunflower Oil

- Production Capacity: 5-500 TPD

- Model Number: Z1617

- Voltage: 440V

- Weight: 500TONS

- Certification: ISO,CE

- After-sales Service Provided: Engineers available to service machinery overseas

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

There are five main stages where there is a potential leak of minor components: Degumming, neutralization, bleaching; winterization and de- odorization. ... View in full-text. Context 2.

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Usage: essential oil

- Type: steam dilstiilation,essential oil distiller

- Voltage: 380V/50HZ, 480V 220V is optional

- Dimension(L*W*H): 1900*840*2000mm

- Weight: 260kg

- Core Components: Heating tube

- Oil type: Essential oil extraction - steam distillation

- Product name: plant essential oil extractor

- Raw material: Stainless Steel SS304/316

- Common extraction rate: Contact us for information

- Function: essential oil

- Package: Packed by wooden box

- Full volume: 100L

- Certification: available, CE/ISO9001

- MOQ: 1 Set

- After Warranty Service: Video technical support, Online support, Field maintenance and repair service

- Local Service Location: Canada, United Kingdom, United States, Italy, Germany, Thailand, Malaysia

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support,attrValueId: 190000883

In sunflower oil production depending on the modernity of production 0.5-5% of the oil remains in the sunflower oilseed meal (Clef & Kemper, 2015). Totally, it reaches up to 25 g/1 kg of sunflower.

The Sunflower Oil Processing Plant offered by Hongde is robust, versatile, reliable and efficient. This Sunflower Oil Processing Plant is based on practically proven technology which is not only energy efficient & environment friendly, but also economical. Please fill the below Enquire Now Form so that we can contact and provide you the best.

FINAL SUNFLOWER PRODUCTION AND PROCESSING - State of the Planet

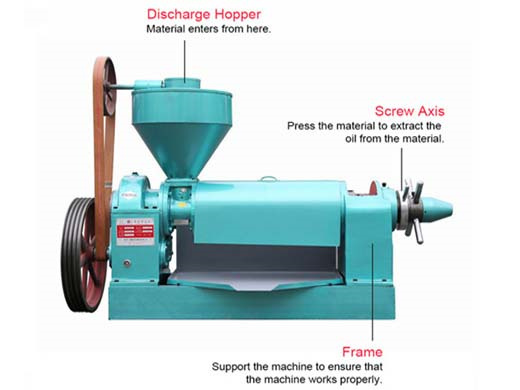

- Usage: edible oil

- Type: Cold & Hot Pressing Machine, small Sunflower oil machine

- Production Capacity: 100%

- Model Number: 6100

- Voltage: 220V/380V

- Power(W): 7.5kw

- Dimension(L*W*H): 1950*1300*1900mm

- Weight: 950 kg

- Certification: ISO CE

- Screw speed: 30-40 r/min

- gear ratio: 15/40x15/55=1

- Dimension: 1950*1300*1900mm

- Output: 150-250kg/h

- Power: Y160M-6-7.5KW

- Vacuum pump: Y90S-4-1.1KW

- Heater: 3KW

- Package: wooden case

- Quality: Top Level

Sunflower oil is low in saturated fat and high in polyunsaturated fat. Oil seed production in Tanzania mainly focuses on ground nuts (40%), sunflower (36%), sesame (15%), cotton (8%) and palm oil (1%). More than half of vegetable oil consumed in Tabora and Tanzania as a whole is imported due to insufficient domestic production.

Prepress solvent extraction relies on exerting medium pressure on the prepared seed to separate the majority of the oil, followed by solvent extraction to separate additional oil from the solids fraction, recovering over 40% oil from the seed in modern crushing plants. In a typical sunflower crushing plant using the prepress solvent extraction.

Bioactive Phytochemicals from Sunflower (Helianthus annuus L

- Usage: Sunflower Oil

- Type: pre-pressed cake oil solvent extraction production

Production Capacity: 400T~500TPD, 400TPD~500TPD - Voltage: 220V/380V

Power(W): depend on the capacity - Dimension(L*W*H): 1200*400*900mm3

Certification: ISO9001 - Residual oil in meal: <1%

Crude oil moisture and volatile matter: <0.3% - Item: pre-pressed cake oil solvent extraction production

- Overseas installation: Yes

Experience life: 30+ years - Business type: manufacturer

The sunflower seed pressing procedure manages to transform about 25?33% of the initial seed weight into oil , while in chemical extraction, the average extracted oil yield is ~42% . As a result of this process, byproducts are generated with a high concentration of nutritional components, including high protein content, reaching around 40?50.

The initial RSSC conductivity was 0.12 mS/cm. To analyze PEF treatment effect on oil extraction firstly the most effective solvent was selected from industrially applied n-hexane, petroleum ether and ethanol. Fig. 3 shows the extraction yields obtained in the sunflower oil extraction using three solvents.

Pulsed electric field assisted sunflower oil pilot production

- Usage: mini machine making for processing oilseed

- Type: mini machine making for processing oilseed, semi-automatic oil press

- Automatic Grade: Semi-Automatic

- Production Capacity: 30~70kg/h

- Model Number: 6YY series 0701

- Voltage: adjustable

- Power(W): 2 KW

- Dimension(L*W*H): 900*850*1550(mm)

- Weight: 1000kg

- Certification: ISO9001

- Suitable objects: Sunflower , Sunflower etc.

- Plant: 10㎡

- Extraction rate: >40%

- Residual oil rate: <5%

- Business type: manufacturer

- Guarantee: 12 months

- Accepted Delivery Terms: FOB, CFR, CIF

- Packing: Wooden package

Sunflower oil pilot-production based on local raw materials assisted by pulsed electric field (PEF), which is produced in terms of oil yield, extraction kinetics and chemical parameters on pilot.

Around 90% of the sunflower grain oil (SFO) produced is for human consumption and almost 10% is used for biodiesel production and industrial applications (Martínez-Force et al., 2015). A projection of this scenario predicts that the production of sunflower grains will grow by at least 20% by 2050 (Domínguez Brando and Sarquis, 2012).

- Does Ukraine export sunflower oil?

- It should be emphasized that Ukraine exports sunflower oil to over than 100 countries of the world, which requires more efficient technologies for its production for the purpose of providing with world demand. For today, there are two methods of extracting oil plant raw materials: press and extraction.

- What are the stages of sunflower oil extraction?

- Sunflower Oil Extraction Stages. Read: Advantages of Green Leaf Manuring. Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging.

- How is sunflower oil extracted?

- A volatile hydrocarbon like hexane is used as a solvent to extract the oil. The harvested sunflower oil seeds are passed over magnets to subtraction any metal traces, and other impurities are getting rid off by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to get pure seeds.

- What is the export/production ratio of sunflower?

- If we compare the export/production ratio of the main products involved in the vegetable oils and proteins markets, we see that sunflower is traded mainly after processing: 55% of the oil volumes were exported in 2018/19, 38% of the meals, and only 5% of the harvested seeds.

- Voltage: 220V/380V