energy saving factory sunflower seed oil expellers in india

- Usage: Sunflower Oil

- Type: Oil Pressing Machine

Production Capacity: 100% - Voltage: 380V

Power(W): Sunflower oil press mill - Dimension(L*W*H): Sunflower oil press mill

- Weight: Sunflower oil press mill

Certification: CE and ISO - Product: Sunflower oil press mill

Raw material: Sunflower Seed - Capacity: from 5T to 2000T Sunflower oil press mill

- Oil residues: less than 1%

- Material of equipment: stainless steel and carbon steel

- Manufacturing experience: 19 years experience in edible oil field

Using life: several decades for Sunflower oil - service: turn-key project and tech consulting

- raw materials: Sunflower seeds

Optional chamber for water cooling is provided on request. In Super Standard Oil Expeller, cone body and gear body is mounted on two-storied bed made from MS Channel, and Girders etc. in order to provide complete alignment as well as stability, resultant to decrease in frictional load at the bearing, and thus electricity saving up to 4-5 KW/ hour.

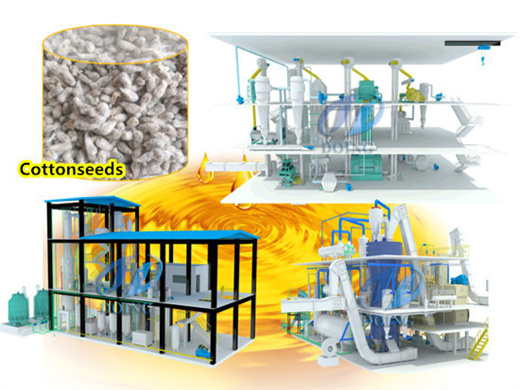

oil processing plant. These oil mill can process a number of oilseeds like peanut, soya, cotton seeds sunflower seeds, corn germ, rape seeds, canola, castor, sesame, neem seed, sheanut, palm kernel and the like. The most important equipment in the entire milling / pressing process is oil expellers which are used for high oil content seeds and.

Expeller with Cooking Kettle, Oil Mill Machinery, Tinytech

-

Model Number: SM-20

Type: Sunfloweroil press machine for sale - purpose: cooking oil

Description: Sunfloweroil press machine for sale - Material: Stainless steel

- color: fresh bright

smell: no objectional odor - original: china

- technology: QIEadvanced technology

cetificates: CE/BV/ISO 9001 - type: Sunfloweroil press machine for sale

- residual oil: less than 6-8%

Cooking kettle has 3 functions, 1. It can hold 40 kg seeds and heated up by steam so that seeds get moisturized till the center of the seed due to steam pressure which is responsible for optimum oil extraction from the seeds. 2. You can increase or reduce flow of seeds going to the expeller so feeding control. 3.

Our Oil Expellers are used for pressing oilseeds like Cottonseed, Sunflower, Groundnut, Soybean, Coconut, Sesame, Mustard and other oilseeds. 'ANAND' a name known for break through and high efficiency in Oil Mill Industry started its operation in 1943 in Lahore (Pakistan) and first expeller was made for cottonseed pressing by the founder of the.

Oil Expeller - Expeller Machine Manufacturer, Exporter in India

- Usage: Sunflower oil

- Type: For oil seed press machine usage

- Production Capacity: 100-2000 ton

- Model Number: JX1236

- Voltage: 380v 440v

- Power(W): As Sunflower oil machhine output every day

- Dimension(L*W*H): As Sunflower oil machhine capacity

- Weight: Depend on Sunflower oil machhine capacity

- Certification: ISO9001

- Item: Sunflower oil machhine

- Material: Stainless steel

- Rate of Sunflower oil extraction: 30-48%

- Process of making Sunflower oil: pretreatment , solvent extraction ,refinery

- Embryo of Sunflower: 12%

- Endosperm of Sunflower: 82%

- Oil rate of press Sunflower: 65%

- Oil residual after pressed: 7%

- Shipping: by sea

- Payment: L/c ,T/T

Shreeji Expeller Industries. Shreeji Expeller Industries is the Indian manufacturer and supplier of oil extraction machinery. and components to oil extraction plants, oil mills, oil refinery plants, and bio-diesel plant production houses. The company incorporated in the year 1992 was established by Sh.

Commercial expeller sunflower seed oil expellers; Domestic oil extraction machine, capacity: 2-5 kg/hr; Standard sesame seeds oil extraction machine, 10 hp; Domestic oil expeller machine, capacity: 3-4 kg/hr; Domestic oil extraction machine, capacity: 2-5 kg/hr; Belt kachi ghani mustard oil machine, automation grade: semi...

9 Bolt KUMAR OI EXPELLER, Capacity: 5-100 Tpd, Automation

- Usage: Vegetable Oil Press

- Type: Cooking Oil Press Machine

- Production Capacity: 3.5 TPD

- Voltage: 380V

- Dimension(L*W*H): 1790*1520*1915mm

- Weight: 1023KGS

- Warranty: 1 Year, 1 Year

- Product name: cold press oil machine with air pressure filter

- Advantage: Labor Saving

- Model: YZLXQ10

- Character: Combined Oil Press

- Color: Yellow and Customerized

- Quality: China Profesional Oil Press Machine

- Delivery: 20 Working Days

- After-sales Service: Provide Longlife Technical Support

- Package: Standard Wooden Case

The expellers are supplied with 2 to 6 stage stack cooker for conditioning the oil seeds before crushing. These cookers are self driven with their independent geared motor.Kumar New Oil_N_Oil Series Expellers are designed for crushing all types of oil seeds like sunflower, Mustard, Groundnut, sesame, soybean, Copra, Palm Kernel, Jatropha, shea.

Company Profile. “A customer is the most important visitor on our premises. He is not dependent on us. We are dependent on him. He is not an interruption in our work. He is the purpose of it. We are not doing him a favour by serving him. He is doing us a favour by giving us the opportunity to serve him.”. Mahatma Gandhi.

Sunflower Oil Press Machine Manufacturers & Suppliers in India

- Usage: Sunflower Oil, Cooking Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 150kg

- Voltage: 220v

- Dimension(L*W*H): 1800*680*1400mm

- Weight: 165 KG

- Core Components: Motor

- Oil type: Sunflower Oil

- Name: Sunflower Bean Soyabean Canola Sunflower Oil Refined

- Used for: Crude oil

- Suitable for: Sunflower /Sunflower oil

- Model: HLJL-50A

- Function: Making Edible Oil

- Application: Edible Oil Production

- Capacity: 60-70kg/h

- Processing Types: Oil Food Processing Line

- MOQ: 1 Set

- Package: Wooden Case

Commercial Oil Pressing Machine 4,50,000.Commercial Expeller Sunflower Oil Press Machine / Sunflower Seed... 75,00,000.Commercial Expeller Corn / Maize Germ Oil Press Machine, Capacity:... 39,00,000.Mobile Number.

Hongde is one of the leading manufacturer in sunflower seed oil processing line. We design complete sunflower oil plant, also we sell a large range of sunflower seeds oil expeller machines. Our objective is to manufacture and supply the most efficient sunflower oil extraction machines to our customers. We have been in the oil processing line.

- Who is the best manufacturer of sunflower seed oil extraction machine?

- GOYUM is the best and reliable manufacturer, exporter and supplier of oilseed crushing machines. Please fill the below Enquire Now Form so that we can contact and provide you the best solution for your requirement. Looking for Sunflower Seed Oil Extraction Machine Manufacturers?

- How to start a sunflower oil mill plant?

- Here we have listed some of the basic machinery required to Start a Sunflower Oil Mill Plant There are various processes involved in Sunflower Oil Mill Plants: Seed Cleaning, Seed Conditioning, Oil Extraction, Oil Filtration, Steam Generation and Oil Filling.

- How are sunflower seeds conditioned?

- The sunflower seed contains 35 ? 40 % oil content and double pressing is required to extract maximum oil, 9 ? 11 % residual oil is left in the sunflower meal which is an excellent source of Animal Feed. The Sunflower Seeds are conditioned using Steam in a Vertical Cooking Kettle. The conditioned sunflower seeds are fed into the chamber.

- What are the processes involved in sunflower oil mill plants?

- There are various processes involved in Sunflower Oil Mill Plants: Seed Cleaning, Seed Conditioning, Oil Extraction, Oil Filtration, Steam Generation and Oil Filling. Prior to extraction, oilseed is passed through the seeds cleaner to remove the impurities such as dust, leaves and metals.

- purpose: cooking oil

- Voltage: 380V