dachang peanut oil extraction daily cook use in lagos

- Usage: Peanut Oil

- Production Capacity: 100% Peanut oil production equipment

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity

- Weight: Depand on your capacity

- Certification: CE/BV/ISO9001

- Raw material: Peanut

- Name: Peanut oil production equipment

- Application: Oil Pressing

- Common capacity: 1-2000TPD

- Character: semi-auto, automatic

- After-sales Service: installation,debugging, training ans service

- Certificate: CE/BV/ISO9001

- Advantage: Energy saving/high oil yield

- Function: press Peanut/solvent extraction

Extracting the Groundnut Oil. Start by adding a tablespoon of water at a time and stir to mix completely. Do not pour the water all at once; because once you add the water more than what is required to extract the oil, the peanut oil cannot be extracted again. So it is always good to add a little water at a time that is why I prefer a.

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

Peanut Oil: Smoke Point, Varieties, and More - Simply Recipes

- Usage: Edible oil

- Type: Vegetable Oil Processing Equipment

- Production Capacity: 60-800 kg/h

- Voltage: 220V/380V

- Dimension(L*W*H): 2000*1100*1950mm3

- Weight: 450 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Peanut Oil

- Product name: Oli Press Machine

- Function: Press Oil Seeds

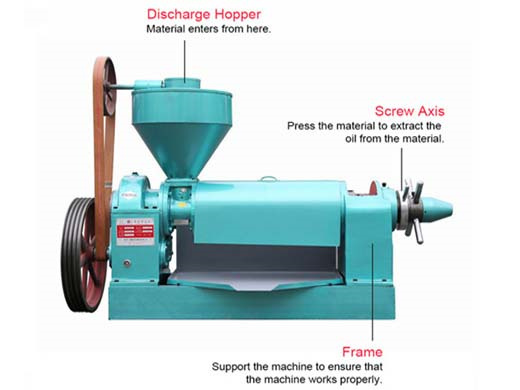

- Processing Types: Screw Pressing

- Application: Peanut

- Advantage: Automatic temperature control

- Material: Carbon

- After Warranty Service: Online support

- pressing power: 15kw-6p

- Capacity: 5 Tons

- Color: White

Peanut oil is made from the seeds of a peanut plant. Most peanut oil is refined, neutral in flavor, and great for high-heat cooking, especially stir-frying and deep-frying, because it doesn’t absorb the flavor of other foods, and also because it has a high smoke point of 450 degrees.

The peanut kernel is primarily used for cooking oil, peanut butter, flour, snack, soup, and dessert. Worldwide, peanut oil accounts for nearly 5.77 million metric tonnes [ 3 ]. The main peanut processing is crushing for oil, contributing to approximately two-thirds of the world’s peanut production, while the remaining is used in food.

Peanut proteins: Extraction, modifications, and applications

- Usage: Peanut Oil

- Type: Oil Pressing Machine

Production Capacity: High - Voltage: 380v 440v or others

Power(W): 7.5kw/h-25kw/h - Dimension(L*W*H): 1200*400*900mm3

Certification: ISO9001 - Name: mini Peanut oil refining plant

Residual oil in meal: ≤ 1% (Peanut) - Solvent consumption:

- Crude oil moisture and volatile matter:

Power consumption: ≤ 15KWh/T - Steam consumption:

- Finished meal moisture:

Color: Choose - Raw material: Peanut

Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent (n-hexane) extraction [29]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

Do use refined peanut oil for high-temperature frying. Do use refined cooking oil if you are concerned about peanut allergies. Do use virgin or cold-pressed peanut oil if you want the peanut flavor. Do reuse peanut oil. Do use peanut oil if you want a heart-healthy cooking oil. Do store unopened peanut oil correctly.

Peanut oil - Wikipedia

- Raw Material Processed: Grass, Rice Husk, Wood Sawdust, Biomass, Straw, Cotton Stalks

- Pellet Diameter (mm): 6 - 10

- Output (kg/h): 1000 - 1500 kg/h

- Voltage: 380V

- Dimension(L*W*H): 3300*1400*3100mm

- Motor Power (Kw): 90

- Weight (KG): 5300 KG

- Core Components: Bearing, Motor, Pump, Gear, PLC, Other, Engine, Pressure vessel, Gearbox

- Product name: Centrifugal Efficient Pellet Mill

- Color: as required

- Raw material: Sawdust,straw,rice husk,alfalfa,Peanut,rubber tree and other biomass

- Pellet Size: 4-15mm

- Capacity: 1-1.5t/h

- Usage: as the substitute of coal and raw oil

- Model: XGJ560

- Lubrication: automatic lubrication system

- Spare parts: mould and roller

- Weight: 5.3t

- After Warranty Service: Video technical support, Online support, Spare parts

- Local Service Location: Malaysia

- Certification: CE & ISO9001

Peanut oil, also known as groundnut oil or arachis oil, is a vegetable oil derived from peanuts. The oil usually has a mild or neutral flavor [1] but, if made with roasted peanuts, has a stronger peanut flavor and aroma. [2] [3] It is often used in American, Chinese, Indian, African and Southeast Asian cuisine, both for general cooking and in.

The Cosmetic Ingredient Review Expert Panel (CIREP, 2001) in a report on the safety of peanut oil concluded: ‘aflatoxins can be produced in stored agricultural crops, such as peanuts, but do not partition into the oils, acids or glycerides’ (CIREP, 2001). However, concerns over the presence of aflatoxin contamination in peanut oil were.

Aflatoxins in peanut oil: food safety concerns | World

- Usage: plant oil extractor for sale

- Type: plant oil extractor for sale

- Production Capacity: 100%plant oil extractor for sale

- Model Number: plant oil extractor for sale

- Voltage: 220V/380V/440V

- Power(W): 22kw

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- Certification: ISO CE

- Product name: Plant oil extractor for sale

- Raw material: Peanut

- Color: according to customer requirement

- Application: Oil Production Line

- Production period: 45-90 days

- Installation period: 60-90 days

- Supplier Type: manufacturer

- Technology support: lifetime

- Material: Food Grade Stainless Steel 304

Thus, the use of peanut oil in human food is frequently overlooked as a source of aflatoxin exposure, yet artisanal oil extraction from contaminated peanuts in local facilities in the developing world results in carryover of these mycotoxins into the oil. Consequently, these peanut oils can have high contamination levels. This review highlights.

Peanut oil, also called groundnut oil or arachis oil, is a cooking oil derived from peanuts. It usually has a mild, nutty flavor. Its high smoke point of 444.92°F (229.4°C) makes it a popular.

- How is peanut oil extracted?

- Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent ( n -hexane) extraction [ 29 ]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

- How can aqueous enzymatic extraction improve the function of Peanut proteins?

- Discuss extraction methods, modifications and applications of peanut proteins. Aqueous enzymatic extraction can efficiently separate oils and peanut proteins. The functionality of peanut proteins was significantly improved after modification. Native and modified peanut proteins can be used for a variety of purposes in foods.

- Which method is used to extract peanut protein?

- The extraction method used significantly affects the structural, functional, and physicochemical properties of peanut protein ingredients. The conventional extraction methods include the press method, leaching process, and alkali-soluble acid precipitation method [ 27 ].

- Can peanut oil be removed by hot pressing method?

- Although up to 80%?90% oil can be removed by hot pressing method, most proteins in peanut meal will be denatured and the content of water-soluble proteins and functional properties will be decreased obviously due to high-temperature treatment. The general cold pressing process is processed in an environment below 60 °C.

- Voltage: 380v 440v or others