customized palm oil expeller laos in congo

- Usage: Vegetable Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 1-20T/D

- Voltage: 380V

- Dimension(L*W*H): 2900X1850X3640

- Weight: 5500Kg

- Core Components: Motor, Pressure vessel, Pump, Engine

- Product Name: screw oil press

- Processing Method: Hot/Cold Pressed Method

- Material: Q235

- Advantage: High Oil Yield

- After Warranty Service: Video technical support, Online support

- Local Service Location: Egypt, Viet Nam, Indonesia, Sri Lanka, Bangladesh, South Africa, Kazakhstan, Nigeria, Uzbekistan, Tajikistan

- Certification: SGS ISO

Alfa Laval has worked alongside palm oil producers since the earliest days of the industry. More than 50 years’ experience has gone into smart palm oil processing solutions for the entire supply chain milling, POME management, refining and more. Our complete range helps you increase yield while meeting increasingly strict environmental.

Over 2.2 million mature palm trees and 300,000 seedlings are spread out across the plantations. Three principle products are produced, crude palm oil, palm kernal oil, and palm kernel expeller. All crude palm oil and palm kernal oil is sold to domestic refiners in the DRC for the production of cooking oils, soaps, and other consumer goods.

Palm Oil Equipment,Palm Kernel Screw Press,Oil Expeller

- Usage: all

- Type: screw press

- Production Capacity: 98%-100%

- Voltage: 220V/380V

- Dimension(L*W*H): 175*66*146

- Weight: 200 KG

- Marketing Type: Other

- Machinery Test Report: Not Available

- Warranty of core components: 6 Months

- Core Components: Other

- Machine Name: deodorization machine crude Palm oil refinery plant equipment

- Raw material: Palm, Palm Kernel

- Product name: Oil Refinery Machine

- Function: Making Palm Oil

- Name: Oil Refinery Equipment

- Application: Palm Oil Production

- Advantage: Energy Saving

- Keyword: Oil refinery machine

- Feature: High Oil Yield Efficiency

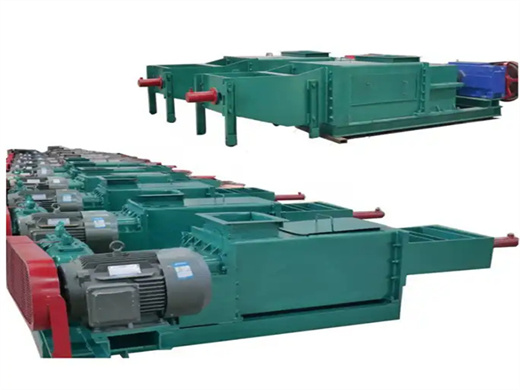

Palm Kernel Oil Expellers / Palm Kernel Screw Press are screw type machines that presses oil seeds in order to extract the oil in the seeds. These seeds are fed from one side of the press, which then enters into the pressing chamber. The palm-kernel machines uses pressure and friction from the screw drives to move as well as to compress the oil.

Expanding and Expelling. Home Edible Oil Processing. Although mechanically the machines used to perform the expanding and the expelling functions share a number of common features, they serve completely different purposes. The expander is a unit assigned to seed or product preparation, whereas the expeller is the machine for mechanical oil.

Kumar’s Palm Kernel (PK) Series Oil Expeller Machine

- Type: Centrifuge

- Marketing Type: Hot sale product

- Warranty of core components: 1 Year

- Core Components: PLC, Bearing, Motor

- Voltage: 220V/380V/415V

- Power: 5.5-75KW

- Weight: 1600

- Dimension(L*W*H): virable

- Application: Liquid Solid Separation

- Centrifugal type: Disc Stack

- Material: 304/316L Stainless Steel

- Operation: Continuous Automatic

- Description: Mechanical Separation Concentration

- Discharge type: Self-cleaning

- Feature: High Efficiency

- Bearing: SKF Bearing

- Speed: 0-5000(stepless Adjustable )

- Bowl Material: Stainless Steel 304/316L/Duplex Steel

Specially designed and manufactured for maximum oil extraction from palm kernel. Minimal residual oil content in the second press cake. Independent gearbox system reduces noise level, consume less power and ensure zero contamination of mineral oil with edible oil. Alloy steel with ultrasonically tested screw shaft with heavy-duty branded bearings.

The palm press was tested with digested palm fruit and average volume of oil extracted, oil extraction efficiency and extraction loss were 0.4 litres, 80% and 20% respectively.The Straining time was 3 minutes. While manually powered, the expeller had a production cost of $100. Download Free PDF.

Design and Fabrication of a Palm Kernel Oil Expeller Machine

- Usage: Cooking Oil

- Type: Oil Press Machine

- Production Capacity: 200kg/h

- Weight: 220 KG

- Core Components: Motor

- Oil type: Palm Oil

- Raw material: Oil s

- Function: Oil Pressing

- Feature: High Capacity

- Application range: Competitive Mini Oil Press Machine

- Advantage: High Efficient

- Oil rate: Meal Residual: 1%

- Package: Wooden Case

- MOQ: 1 Set

- Operation: Automatic Operate

- Advantage 2: good after-sales

The choke mechanism Machine Capacity: The theoretical capacity of the expeller was determined as 280.6kg/hr using a modified form of the equation given by (Adetola et al (2014) as: Q c = 60 π 4.

Muar Ban Lee Group is a world-leading palm kernel expeller manufacturer specializing in palm oil machinery and oil seed crushing machinery. We provide "One Stop Service" in setting up Palm Kernel Crushing Plants from Plant Design and Fabrication to Installation and Commissionning. With our in-depth knowledge of the industry, our expertise and.

Palm Kernel Oil Expeller for Cold Pressing of Palm Kernel Oil

- Usage: Edible oil, Edible Oil

- Production Capacity: High

- Model Number: Palm oil processing machinery, Palm oil processing machinery

- Voltage: Depend on Palm oil processing machinery capacity

- Power(W): Depend on Palm oil processing machinery capacity

- Dimension(L*W*H): Depend on Palm oil processing machinery capacity, Depend on the capacity

- Weight: Depend on Palm oil processing machinery capacity

- Steam consumption: 450kg/T oil

- Waste bleaching earth oil content: Less than 35%

- Color: Based on Palm oil processing machinery

- Use: Use Palm oil processing machinery

- Residual oil in meal: Less than 1%

- Crude oil moisture and volatile matter: Less than 0.30%

- Item: Palm oil processing machinery

Palm kernel oil is a type of vegetable oil which is high in saturated fat and Omega 6, presenting serious health concerns. It is derived from the palm kernel, grown on the African oil palm tree. Oil palms originated in West Africa. Palm kernel oil is an important part of the oil market in the world, at present, it is more than 30% in the oil.

The New EK-300-K is designed and built for profitability optimization. MBL devoted monumental efforts in R&D of the EK-300-K. R&D started in 2013 headed by professional engineer with a team of six experienced technical engineers through actual oil extraction test. In total, MBL accumulated 18 months or 9,000 hours of in house field test on the.

- Where can oil palm be grown in the Congo Basin?

- Most of the roughly 280 million hectares (Mha) of additional land suitable for oil palm in the Congo Basin are found in the Democratic Republic of Congo (60%), Cameroon (11%) and the Republic of Congo (10%). Many heavily forested countries in the Congo Basin are setting national targets to increase production to meet national and regional demands.

- Will oil palm production increase in the Congo Basin?

- Land area allocated to oil palm increased by 40% in the Congo Basin and five additional top-producing countries in Africa between 1990 and 2017. Without intervention, future production increases in the region will likely come from expansion rather than intensification due to low crop and processing yields, possibly at the expense of forest.

- How has the Congo Basin impacted oil production?

- Many heavily forested countries in the Congo Basin are setting national targets to increase production to meet national and regional demands. Land area allocated to oil palm increased by 40% in the Congo Basin and five additional top-producing countries in Africa between 1990 and 2017.

- Can palm oil mills reduce deforestation in the Congo Basin?

- Sustainability strategies initiated by companies and aimed at certifying palm oil mills are unlikely to be effective at curbing deforestation in the Congo Basin. Smallholder farmers are an engine of growth in the regions palm oil sector, and recent evidence suggests they are actively clearing forest to expand.