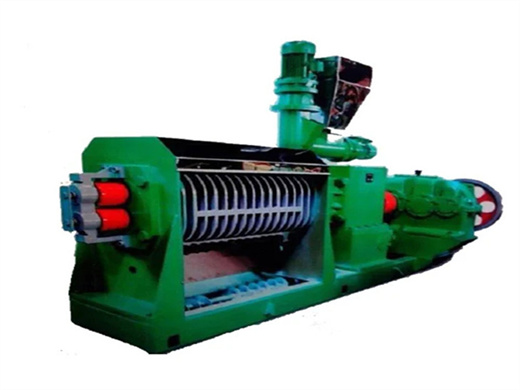

crude palm kernel oil press machine in lesotho

- Type: Rotary Drying Equipment

- Application: Drying Processing

- Voltage: 220v-10kv

- Power: 20-35kw

- Dimension(L*W*H): Customized

- Weight (KG): 6500

- Marketing Type: New Product 2020

- Warranty of core components: 1 Year

- Core Components: Motor, PLC

- Heating Method: Biomass, natural gas, diesel, coal

- Material: SUS304, SUS304L, SUS316, SUS316L, Ti, Other

- Product name: Palm Fiber Rotary Dryers

- Vaporization(t/h): 0.76-2.25

- Early moisture(%): 30-45%

- Final moisture(%): 15-18%

- Temperature range(℃): 100-180℃

- Application material: Cocopeat,Palm coir,Palm fiber, palm slag, etc

- Feature: Continuous Drying Machine

- After-sales Service Provided: Field installation, commissioning and training

- After Warranty Service: Video technical support

- Certification: ISO

For decades, Alfa Laval has worked closely with palm oil mills in the development of reliable, efficient solutions for converting palm fruit into crude oil. Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack centrifuges optimized for mills, as well as.

Palm Oil press station: Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Digester Machine. The fruits are then digested in the digester.

Palm oil press machine

- Usage: edible oil

- Type: Vegetable Oil Machine

- Production Capacity: 80kg/h, 500kg/h, 100kg/h

- Model Number: LD1

- Voltage: 220V/380V/440V

- Power(W): 11KW

- Dimension(L*W*H): 1.5*2.6*3.6M

- Weight: 0.5-10T

- Raw material: Palm, Palm Kernel

- Application: all kinds of oil s

- Function: get grade 1 cooking oil

- Feature: Multifunction High Efficient

- Model: LD88

- Quality: 15 years service time

Palm Oil Press Station: Separate palm fruit and kernel, and palm oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Palm fruits through elevator and conveyors, enters into upper steaming boiler of oil.

The palm kernel oil press is the same as the conventional oil press and can be used in general. Throughpressing, we can get crude palm kernel oil. 7. Palm Kernel Oil Filtration Equipment. Crude palm kernel oil contains a lot of impurities, and palm kernel oil filtration equipment can enable us toobtain higher quality palm kernel oil.

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

- Type: Screw

- Configuration: PORTABLE

- Power Source: AC POWER

- Lubrication Style: Lubricated

- Mute: Yes

- Model Number: SLTS-4.5V

- Voltage: 220V/380V

- Dimension(L*W*H): 1020*540*1035mm

- Weight: 100kg

- Working Pressure: 7 bar, 8 bar, 12 bar, 12.5bar

- Marketing Type: Other

- Warranty of core components: 2 years

- Core Components: PLC, Pressure vessel, Engine, Gear, Motor, Pump, Bearing, Gearbox

- Gas Type: Air

- Product name: Single phase Air Compressor

- Cooling method: Air Cooling

- Application: General Industry

- Motor: IP55

- Power: 3.7kw-9kw

- Color: Customized Color any color

- Capacity: 100~250L/min

- Drive method: Driect Drive

- MOQ: 1pc

- Consumable parts: Air Filter

The full set of Palm Kernel Oil (PKO) Processing Machines include Husker, Crusher, Cooker, Oil Press Expeller, Oil Filter, Oil Refinery Machine, etc.. Oil Capacity: 1~1000 Tons/Day. Oil Yield: >45%. Oil Residual in Cake:

Palm Oil Press Station: Separate palm fruit and kernel, and palm oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Palm fruits through elevator and conveyors, enters into upper steaming boiler of oil.

Palm Kernel Oil Manufacturing Process With Flowchart - Hongde

- Usage: Palm Oil

- Type: Palm oil solvent extraction equipment

- Production Capacity: Palm oil solvent extraction equipment

- Model Number: oil extraction machine

- Voltage: Palm oil solvent extraction equipment

- Power(W): according the capacity of oil solvent extraction machine

- Dimension(L*W*H): according the capacity of oil solvent extraction machine

- Weight: according the capacity of oil solvent extraction machine

- color: Yellow

- capacity: 20-300TPD oil solvent extraction machine

- madel: Palm oil solvent extraction equipment

- function: solvent extraction Palm oil

- extractor system:

- usage:

- solvent name:

- residual oil content: maxmum 1%

- material:

- Packaging Detail:

The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing. Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing.

Palm Kernel Oil Pressing Equipment: crusher, dryer, oil expeller. Application: High efficiency crude oil pressing from palm kernel with low oil residual. Palm Kernel Oil Pressing Plant Flow Chart: Main process in palm kernel press line: Palm kernel Cleaning : It is used for removing the iron impurities, stone, fiber and pthers.

Palm Oil Pressing Station - Palm Oil Mill Machine Leading

- Usage: oil solvent extraction plant

- Type: oil solvent extraction plant

Production Capacity: 30~100TPD(24hrs), high - Voltage: according to capacity

Power(W): depend on the capacity - Dimension(L*W*H): 1200*400*900mm3

Solvent consumption: <2Kg/T (No.6 solvent oil) Finished meal moisture: <13% (adjustable - Power consumption: ≤ 23KWh/T

- Residual oil in meal: <1%

Crude oil moisture and volatile matter: <0.3% - Refining Consumption: 1%

- Phosphoric Acid: 2~3 kg/T Oil

Waste Bleaching Earth Oil Content: 25% to 35 % Digesting temperature keeps at 95-100℃ about 20 minutes. Palm fruit after digesting enters into screw oil expeller for palm oil pressing. The equipment list of pressing station: 1.Fruit Elevator 2.Digester Feed Conveyor 3.Digester Feed Conveyor 4.Fruit Recycle Conveyor 5.Digester 3000 Litter 6.Screw Press P10 7.Crude Oil Gutter 8.Sand Trap.

Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel. Main station description. 1. Sterilize As the first step in palm fruit crushing, sterilization is crucial to the quality of palm oil. 2.Threshing The main function of threshing is to separate the palm fruits from the fruit bunches.

- What is palm kernel oil pressing process?

- Palm kernel oil pressing. Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing.

- What is palm kernel oil extraction machine?

- Palm Kernel Oil Extraction Machine is divided into two types: special palm kernel oil press and conventional oil press. Purify the impurities within the oil by clarifying and filtering the crude palm kernel oil The quality of palm kernel oil obtained through above processing steps is high and enough to reach the standard of cooking oil.

- What is palm oil processing technology?

- Palm oil processing technology involves machines that are developed to make palm oil from palm fruit. These machines are : palm fruit sterilizer machine, palm fruit thresher machine, palm fruit digester and presser machine, crude palm oil clarification machine, palm oil dryer machine and palm kernel recovery machine.

- What are the methods of palm kernel oil production?

- For large scale palm kernel oil production, there are two oil processing method, one is mechanical pressing, the other is solvent extraction. Mechanical pressing mainly adopts large scale oil press to squeeze oil, while solvent extraction utilizes solvents, such as hexane, to extract oil.

- Voltage: according to capacity