cost of palm oil processing extractor in cape town

- Voltage: 220V/380V

- Power: 7.5kw

- Dimension(L*W*H): 1860*1660*1680

- Weight: 120-1800kg

- After-sales Service Provided: Engineers available to service machinery overseas

- Certification: CE ISO

- Color: Optional

- Price Level: Wholesale factory price oil press machine

- Energy consumption: Energy-saving Palm oil press

Report Overview: IMARC Group’s report titled “Palm Oil Processing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a palm oil processing plant. It covers a comprehensive market overview to micro-level information such.

3.1.4 Digestion of the fruit. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of beater (stirring) arms.

What are the main costs of palm oil production and processing?

- Usage: Palm OIL, Cooking Oil

- Production Capacity: 20tpd-100%

- Voltage: 220V,380V,440V

- Dimension(L*W*H): 1950x1300x1900mm

- Weight: 650 kg

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Raw material: Palm,etc

- Name: Palm/Palm/Palm oil expeller machine price

- Function: Making Edible Oil

- Advantage: Energy Saving

- Product name: Screw Press Oil Expelle

- Application: Screw Oil Expeller

- Material: 304 Stainless Steel

- Color: Clients' Requirements

- Item: Edible Oil Press

- After Warranty Service: Video technical support, Online support, Field maintenance and repair service

- Local Service Location: Kazakhstan

- Certification: ISO9001

Palm oil production costs vary by region, scale, production technology, energy prices, and other factors. Following are some of the factors that affect the cost of palm oil production: Labor cost: including labor costs in planting, picking, processing and other links. Land rent or purchase cost: Palm oil plantation requires a large area of land.

The equipment price is around $20,000~$30,000 for establishing a 5~10 ton/d small palm fruit oil milling factory. About $60,000 is needed as equipment investment to run a complete palm oil milling plant with capacity of 50 ton/day. If you want to build a complete oil mill plant including both palm fruit and palm kernel oil extraction, with.

Palm oil: Processing, characterization and utilization in the

- Usage: Palm OIL, Cooking Oil

- Type: Oil Extraction Machine

- Production Capacity: 60-850kg/h

- Voltage: 220V/110V

- Dimension(L*W*H): 1200*400*900mm

- Weight: 260 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Palm Oil

- Raw material (1): Palm\ Palm\ Rape \ Palm\ Palm

- Raw material (2): Palm \ Palm kernal\ Palm , etc

- Material: Stainless steel

- Machine color: Blue\ Customized

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: India

- Certification: S G S/CE

The oil palm tree is an ancient tropical plant that originated from West Africa. Palm oil has centuries? long use as food and medicine. This review covers the recent significant materials found in the literature on palm oil processing, refining, and use in frying especially in blends with other vegetable oils.

The full set of Palm Kernel Oil (PKO) Processing Machines include Husker, Crusher, Cooker, Oil Press Expeller, Oil Filter, Oil Refinery Machine, etc.. Oil Capacity: 1~1000 Tons/Day. Oil Yield: >45%. Oil Residual in Cake:

Palm Oil Production Process: A Step-by-Step Guide

- Usage: Palm Oil

- Type: set of machine

- Production Capacity: 100%

- Voltage: 220V/380V, 220V/380V

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1500 KG

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, Engine

- After-sales Service Provided: Engineers available to service machinery overseas

- Material: Carbon Steel/SS

- Function: Palm pretreatment and oil extraction

- Raw material: Palm, Palm Kernel

- Color: as you wish

- Advantage: Automatic as you require

- Company type: manufacturing and sales

- Years of factory: 60 years

- Service: full service,design to after-sales

Unveiling Palm Oil Production Process Steps. Refining Process-Starting a Palm Oil Refining Plant Cost. Solvent Extraction Process-Palm Oil Production Plant. Extraction Process-Palm Oil Extraction Machine for Sale. Threshing Process-Threshing Drum for Palm Oil Mill Plant. Fractionation Process-Palm Oil Crystallization & Cooling.

3.1.6 Clarification and drying of oil 3.1.7 Oil storage 3.1.8 Kernel recovery. 3.2 Process equipment design and selection criteria. 3.2.1 Batch systems 3.2.2 Semi-continuous systems. 3.3 Plant sizing 3.4 Process technology/capital investment considerations. 4. TRADITIONAL TECHNIQUES AND INNOVATIONS IN SMALL-SCALE PALM OIL PROCESSING. 4.1.

Water consumption and wastewater generation from small-scale

- Usage: Palm Oil

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: 80-100kg/h

- Dimension(L*W*H): 1700*950*1650

- Weight: 780 KG

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump

- Raw material: Palm, Palm Kernel

- Product name: Oli Press Machine

- Application: Palm Oil Production

A review of the literature shows that both dry and wet methods of palm oil extraction are used by small-scale processing mills in Ghana (Poku 2002; Adjei-Nsiah et al. 2012; Osei-Amponsah et al. 2012). The method of palm oil extraction influences the quantity of water demand and wastewater generated.

4.1 Mechanical extraction. Pounding (digestion) and oil extraction are the most tedious and essential operations in traditional palm fruit processing; therefore early efforts concentrated on these tasks. In small-scale processing, digestion, the breaking up of the oil-bearing cells of the palm fruit’s mesocarp, is the most labour intensive.

- Why palm oil processing machine is not available in Africa?

- Since many Africa customers, especially in Ghana, Nigeria, and other countries, requires relatively small scale palm oil making machine. But, most of the Palm Oil Machinery Manufacturers can’t supply the palm oil processing machine with such small scale capacity.

- What is palm oil processing equipment?

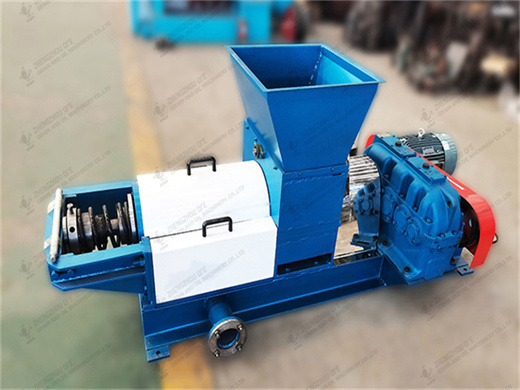

- The palm oil processing equipment includes sterilizer, thresher and oil presser ,oil filter.The above picture is screw type palm oil extraction machine.The capacity of this small palm oil extraction machine is 8-12TPD (tonnes per day), which is the best selection for small capacity palm oil production.

- How Hongde palm Machinery Works?

- Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of palm oil production business. Palm kernel is an important kind of by-product from palm oil extraction plant.

- Is palm oil processing machine suitable for small scale business?

- But, most of the Palm Oil Machinery Manufacturers can’t supply the palm oil processing machine with such small scale capacity. So, it is not easy for small scale business man or small scale farmers to start their own palm oil production business. Fortunately, we have palm oil processing machine that is designed for small scale capacity.