copra oil pressing oil sunflower production in bangladesh

- Model Number: AM20

- Type: Sunflower oil extraction plant making processing machine price

- deodorization: continuous deodorizaiton

- Description: cold and hot press

- Material: Stainless steel or CS

- color: fresh bright

- smell: no objectional odor

- original: china

- technology: new technology

- cetificates: CE/BV/ISO9001

- type: Sunflower oil extraction plant making processing machine price

- oil content: 18--21%

The company invested in an oil mill for processing, and their product aims to be the first sunflower oil sold in Dhaka supermarkets that comes from Bengali farmers. NCPL also signed an agreement with the RDC activity to establish production and marketing groups among farmers in the Patuakhali and Barguna districts of coastal Bangladesh from.

Processing copra oil. Traditionally, processors feed flaked copra into stacked cooking and drying vessels, which reduce the moisture levels down to about 3 or 4% by weight. Then, dried flakes are crushed in a screw press expeller to separate the copra oil from the solid meal. Containing up to 70% oil by weight, coconuts have the highest oil.

sunflower oil processing machinery in bangladesh

- Weight (KG): 980

- Core Components: PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

- Type: Cooking Equipment, Cooking Equipment

- Application fields: Vegetable processing plant, Meat processing plants, Snack food factory, Dairy products factory, Seasoning plant, Cooking oil factory

- Machinery Capacity: 15-450KG

- Machinery Function: cooking, frying

- Name: Food Cooking Mixer Machine

- Material: Full body stainless 304

- Pot size: 50L~800L

- Temp. Control: accurate wireless temp.control

- Heating source: gas, steam, electricity, thermal oil

- Agitation: planetary mixing, adjustable speed

- Dsicharging: auto tilting to 90 degrees

- Scrapers: thick Tef-lon material, endurable high temperature and anti corrosion

- Motor reducer: silent mode, no need maintenance

sunflower oil press machine. QIE grain and oil machinery co., LTD is a company specializing in the production of grain and oil machinery and equipment, scientific research, manufacturing, sales for the integration of large-scale private enterprises, the company with the mechanical design and research institute of henan province, henan university of technology (the former college of food.

According to the Fortune Business Insight, the global sunflower oil market size was worth $18.5 billion in 2020, and is expected to reach $29.59 billion in 2028, exhibiting a compound annual growth rate (CAGR) of 6.12 per cent during the forecast period. More than 90 per cent of Bangladesh’s demand for sunflower oil is met through imports as.

Coconut/Copra Oil Production

- Usage: Sunflower Oil

- Production Capacity: 5-500 TPD

- Model Number: X1792

- Voltage: 440V

- Weight: 500TONS

- Certification: ISO,CE

- After-sales Service Provided: Engineers available to service machinery overseas

The process of coconut oil production is not complicated. There two traditional processing method of coconut oil: dry processing (make oil from copra) and we processing (make oil from fresh coconut). Copra Oil Pressing Process. The followings are some photos about a 20 TPD oil pressing and 10 TPD refining plant we built before in the Philippines.

The client can install our sunflower oil mill machine and start their own production of the crude sunflower oil production. The complete setup is handled and managed by our company from installation to production. All the sunflower oil press machines are guaranteed against making defects and come with a special warranty of 1 year. Machine Usage.

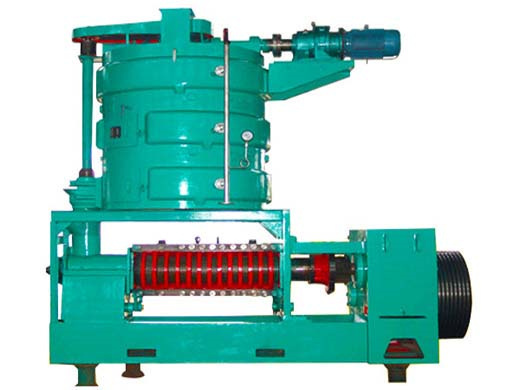

Large Capacity Oil Processing Machine

- Usage: Sunflower Oil

- Production Capacity: 400~600kg/h

- Model Number: 6LD

- Voltage: 220V/380V

- Power(W): 18.5kw

- Dimension(L*W*H): 1500*1600*2500mm

- Weight: 2000kg

- Certification: ISO9001

- Product name: vegetable oil refinery plant

- Raw material: Sunflower Seed

- Advantage: Energy Saving

- Machine Material: Part of are stainless steel

- Warranty: 1year

- Residual: Less than5%

- Supplier strength: with 30 years experiences

- Machine color: According customer needs

- Item: vegetable oil refinery plant

This Expeller has Two Chambers made of Cast Steel. Feed Side: 16″ x 50″ Long, Discharge Side : 16″ x 50″ Long. Hard Faced Worm Assembly, Discharge Ring. Main Worm Shaft can be withdrawn without disturbing the Gear Box. Chamber Lifting system is motorised. Kettle : 8 Stages with Steam Jackets of 78”for efficient cooking of Seed.

Discover production data of Refined Sunflower Oil in Bangladesh. Get production volume, price data, trends, and more. The information below is based on the FAO code 0268 (Oil, sunflower).

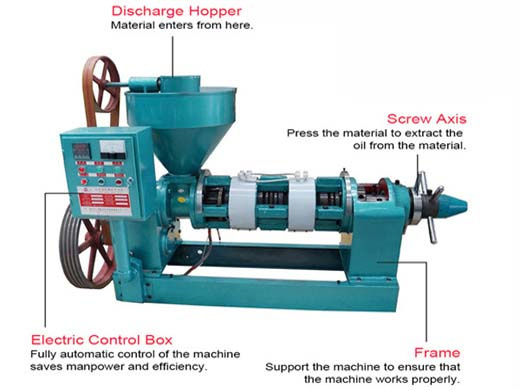

Coconut Oil: Chemistry, Production and Its Applications - A

- Usage: Sunflower Oil

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Model Number: QIE-lp075

- Voltage: 220V

- Power(W): 5.5kw

- Dimension(L*W*H): 46*32*36cm

- Weight: 130kg

- Certification: ISO9001

- Product name: best price screw oil press for oil seeds

- Item: Vertical Oil Press

- Advantage: Energy Saving

- Warranty: One Year

- Function: Hot Press

- Feature: Multifunction

- Product: Oil Reach

- Section: Pressing Section

- Application: Oil Production Line

- Use for: Vegetable Cooking Oil Pressing Machine

C oconut oil is produced by crushing copra, the dried kernel, which contains about 60-65% of the oil. The oil has the natural sweet taste of coconut and contains 92% of saturated fatty acids(in.

For Sima Sana, a resident of Tildanga, Bangladesh, sea-level rise, increased cyclones, and intensifying salinity was taking many of the traditional livelihood options off her plate. “High tides and cyclones are bringing salinity to our lands and destroying our crop production every year. We lost our standing rice and vegetable crops due to tidal flood, intrusion of saline water during normal.

- How is copra oil made?

- Copra oil is pressed from dried coconut meat. Harvesting coconuts for copra is a labor-intensive process. Farmers and plantation workers manually remove the fibrous outer husk, then split open the coconut shell to drain the liquid.

- How is copra pressed?

- After grinding, cracking, and flaking, copra can be pressed like other oilseeds to extract the valuable oil. Copra drying process. Traditionally, processors feed flaked copra into stacked cooking and drying vessels, which reduce the moisture levels down to about 3 or 4% by weight.

- What is copra used for?

- Copra, after extraction of oil, leaves a residue which is palatable oil cake (or copra meal or mash). It is used in animal feeds, mainly for ruminants. It is used as fodder for horses, cattle, sheep and deer. Its high protein content (and oil content) is fattening for stock.

- How is dry copra extracted?

- More commonly, the dry copra is first extracted by the solvent-free method using expellers to obtain better quality coconut oil. Then the residue is processed through solvent extraction plant using food-grade hexane as a solvent to extract the residual coconut oil (8 to 12%). Dry copra may be extracted directly in solvent extraction plants.