coconut oil leave pellet machine in malawi

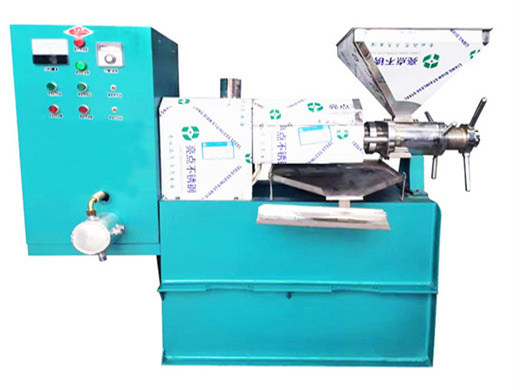

- Usage: Coconut OIL, All kinds of oil seeds

- Production Capacity: 8-10T/H

- Voltage: 220V/380V

- Dimension(L*W*H): 2200*1650*1750mm

- Weight: 3500 KG

- Warranty: 1 Year, One Year

- Core Components: Other

- Oil type: Coconut Oil

- Capacity: 8-10 t/h Coconut Oil Mill Machinery

- Screw diameter: 130mm Coconut Oil Mill Machinery

- Raw material: Coconut ,Coconut, Argan

- Application: Screw Oil Expeller

- Advantage: Simple Operation

- Color: Optional Coconut Oil Mill Machinery

- Certification: CE ISO

Factory for coconut pellet plant. 1. Convenient traffic. The factory should be in the place with convenient transportation, which helps raw materials import and final pellets export. It would be better that the factory is near where abundant raw materials can be supplied, which can lower the transportation cost. 2.

The drying machine used for 500kg/h coconut shell pellet line is airflow wood dryer which consists of heater, feeder, drying tube, cyclone separator and blower. The following information shows its working steps for drying coconut shells: * Use wood feeder to feed coconut shells into drying tube. * Use air heater to heat airflow.

Coconut Shell Pellet Plant Production Line - Herm machine

- Usage: automatic oil refine machine

- Type: automatic oil refine machine

- Production Capacity: 1-100T/D

- Model Number: MN6

- Voltage: 380V/440v

- Power(W): 20-50KW

- Dimension(L*W*H): depond on capacity

- Weight: depond on capacity

- Certification: ISO9001/BV/CE

- Main export countries: Asia,Africa,Latin American,Malaysia...

- Packaging: Glass Container,Plastic Container

- Grade: first Grade

- refined oil: 1st grade

- oil content: 35%-48%

- fatty: 40~60.7

- protein: 20~37.2

- phosphlipid: 1.25~1.75

- saccharides: 5~15

- Refiney type: automatic oil refine machine

Packaging. Last but not least, coconut shell pellets should be appropriately packed. In the process, you only need to place the bags in proper place. All the following filling, weighing, conveying, sewing and sealing are done automatically. Weighing sensor and adjuster are designed on biomass pellet packing machine.

Advantages of Coconut Shell Pellets. High calorific value and cost-effective: the calorific value of coconut shell pellets is 20.8MJ/kg, which is cost-effective regarding its much lower price. Renewable: different from fossil fuels such as coal and natural gas which is expendable (formed in a very long time), coconut shell pellets are renewable.

Coconut Shell Pellet Machine from Leading Manufacturer of

- Usage: cold pressed Coconut oil machinery

- Type: cold pressed Coconut oil machinery

- Production Capacity: according to the specification of cold pressed Coconut oil machinery

- Model Number: according to specification of cold pressed Coconut oil machinery

- Voltage: 220V/380V/440V

- Power(W): Capacity

- Dimension(L*W*H): according to specification of cold pressed Coconut oil machinery

- Weight: according to specification of cold pressed Coconut oil machinery

- Certification: ISO9001

- Machinery type: cold pressed Coconut oil machinery

- Usage range: all seeds

- Function: cold pressed Coconut oil machinery

- port: qingdao

- Warranty: 1year

- engineer abroad service: yes

- Spare parts: supply

- factory strength: more than 30 years experience

- guide installation service: yes

- Color: at the customer's request

Coconut shells are wastes from the production of coconut milk, desiccated coconut, dried coconut and coconut oil. Coconut shells have been used to make charcoal, activated carbon and handicrafts. In recent years, coconut shells become a popular biomass resource for renewable energy to substitute fossil fuel through pelletizing.

The fruits of coconut palm tree are high in palm crown. Coconut shells are a kind of waste by-products of coconut production including coconut oil, desiccated coconut, dried coconut and coconut milk. But these waste shells are proved to have a very high calorific value and this makes coconut shell an ideal biomass material for making fuel pellets.

CoCoMaN Coconut Machines

- Usage: for Coconut

- Type: Oil press

- Voltage: 220/110V

- Dimension(L*W*H): 450*180*305MM

- Weight: 15KG

- Core Components: Motor

- Product name: Oli Press Machine

- Function: Press Oil Seeds

- Material: Stainess Steel

- Application: for Coconut

- Advantage: Energy Saving Low Residual

- Feature: High Oil Yield Efficiency

- Keyword: Mini Oil Expeller

- After Warranty Service: Video technical support, Online support

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support,attrValueId: 190000883

Specifically designed for coconut processing from dehusking to coconut oil extracting, coconut husk processing and coconut shell processing. We have exported and installed our coconut machines in countries such as Indonesia, Nigeria, Ghana, Papua New Guinea, Fiji, Tahiti, Bahamas, Dominican Republic, Guyana, Ecuador and Mexico. Ask Us.

Coir Fiber after Crushing. Coir pith pellets are made from the coconut's fibrous husk (known as coir) that is bound together by lignin (known as pith), by using a pellet machine. The resulting coir pith pellet is reduced in size by about 30%~60% over the same amount of coir pith in an uncompressed form, making it easier to transport than.

Oil Expeller Manufacturer | Copra Oil Expeller Machines - MBL

- Usage: Coconut OIL

- Type: Raw vegetable oil equipment

- Production Capacity: 10-800T/D

- Model Number: JINXIN

- Voltage: 220V ,380V

- Power(W): According to the capacity of Raw vegetable oil equipment

- Dimension(L*W*H): Our engineer will design for you according to your capacity

- Weight: According to Raw vegetable oil equipment

- Certification: CE.BV. ISO

- Supplier type: Manufacturer of Raw vegetable oil equipment

- Features: high quality Raw vegetable oil equipment

- Taste,smell: Has the inherent Coconut oil taste and smell,non odor

- Moisture and volatile matter%: less than 0.1

- Insoluble wastes: less than 0.05

- Acid value mgKOH/g: less than 1

- Peroxide value mmol/kg: less than 6

- Saponified matter content%: less than 0.03

- Solvent residual(mg/kg): no

- Heating test 280 degree: yellow color is constant, red color augmenter less than 0.4

The moisture content of copra should not be more than 5%, based on M.E.O.M.A Standard. After 1st pressing. 16% to 20% oil content remain in cake. After 2nd pressing. 9% to 10% oil content remain in cake. Worm & Collar / Worm Screw. Hardfacing on worm & collar (worm screw) Thickness of hardfaced layer : 6~8mm. Longer life span.

The pellets had an average diameter and length of 10 mm. Pelletization significantly increased the bulk density from 30 kg/m? of the original coconut jelly and 70 kg/m? of ground dried coconut.

- What is the cost effective machinery for coconut oil extraction?

- For small or medium size coconut oil mill plant, the screw coconut oil expeller is the cost effective machinery in the from these aspects, including oil yield, investment cost, operation and maintenance. Coconut oil expeller machine is now the most commonly used machinery for coconut oil extraction.

- Who are the best coconut oil extraction machine manufacturers in India?

- Micro Fab Engineers is the best coconut oil extraction machine manufacturers in India at a reasonable cost. We a team of professionals are working with the latest technology and using a high- grade components to ensure high quality. Are you wondering about the coconut oil manufacturing machine price in India?

- Why should you choose a coconut oil expeller?

- The coconut oil expeller, we provide is highly appreciated by the customers for its various quality features such as fine and smooth operation. In addition, this machine is tested on various parameters to meet quality standards. The above machine combination is for reference only. Equipment list may vary for different business plans.

- Who are cocoman coconut machines?

- Based in Malaysia, a country where coconuts are one the main agricultural product, we have years of experience in designing and developing coconut machines focusing on qualities and reliabilities. Since 2003, we are one of the best known manufacturer and exporter of CoCoMaN coconut machines.