coconut oil fractionation machinery technology in congo

- Usage: Coconut oil

- Type: Vegetable Oil Processing Equipment

- Production Capacity: 3-300T/DAY

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1700*1300*1750mm

- Weight: 30 KG, 30tons

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Coconut Oil

- Advantage: Energy Saving Low Residual

- Material: steel,carbon steel

- residual oil in meal: less than 1%

- Acid value: less than 1.0mg koh/g

- Function: crude oil refinery to edible oil

- Dimension(L*W*H): : 1700*1300*1750mm

- indine value: 44-46 gl/ 100g

- Raw material: crude vegetable oil

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: Egypt, Turkey, Italy, France, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, Chile, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

- Certification: ISO9001,CE

Improvements in solid fat properties to stabilize fat products are of great interest. For this purpose, a new fractionation process based on crystallization of low-viscous emulsions, the so-called emulsion fractionation process, has been developed using model emulsions of coconut oil, water, and sucrose ester laurate (L-195).

Similar to palm kernel oil, coconut oil (CNO) is a vegetable oil that contains a multi-component mixture of triglycerides containing 50% lauric acid and 35% of C16 to C18:2 (Canapi et al., 2005) which can be fractionated for confectionery products. Coconut oil has hardness, mouth feel and flavour release

Dry fractionation of coconut oil by melt crystallization

- Usage: Coconut oil crushing machine

- Type: Coconut oil crushing machine

- Production Capacity: 10T-3000T/D

- Model Number: Jinxin Coconut oil crushing machine

- Voltage: 220v / 380v or local voltage

- Power(W): Depend on Coconut oil crushing machine capacity

- Dimension(L*W*H): Depend on Coconut oil crushing machine capacity

- Weight: Depend on Coconut oil crushing machine capacity

- Certification: ISO9001

- Product name: Coconut oil crushing machine

- Electric Consumption: Depend on Coconut oil crushing machine capacity

- Handling capacity: Depend on Coconut oil crushing machine capacity

- Function: Making Coconut into small pieces

- Raw material: Coconut

- Export markets: All over the world

- Delivery time: 25-45 Days

- Machine color: Depend on customers' request

- Supplier Type: Manufacturer

- Suitable for: Coconut and other plants seed

Abstract. Layer melt crystallization was applied for the dry fractionation of multi-component mixtures using coconut oil as a model substance. The aim of the experiments was to optimize the crystallization parameters (e.g. crystallization temperature, melt temperature, cooling rate, agitation speed) in order to obtain the solid fraction with a.

avocado oil standards for ΔK; therefore, the limit used by the Interna onal Olive Council (COI/T.15/NC No 3 /Rev. 14) for extra virgin olive oil (ΔK< 0.01 ) is used for comparis on.

Emulsion Fractionation of Coconut Oil: A New Fractionation

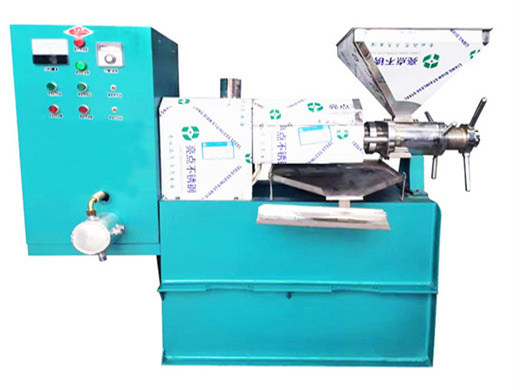

- Usage: Coconut OIL, All kinds of oil seeds

- Type: Oil Extraction Machine

- Production Capacity: 60%

- Voltage: 220V/380V

- Dimension(L*W*H): 1200*780*1400mm

- Weight: 760 KG

- Core Components: Motor

- Oil type: Coconut Oil

- Product name: home use oil presser

- Keyword: Coconut oil press machine

- Raw material: Oil Seeds

- Function: Oil Pressing

- Color: Customizable Color

- MOQ: 1 Set

- Package: Wooden Case

- Method to press: Screw Squeezed Press

- Keep working: Long Time

- Application: Food Industry

Coconut oil was fractionated to get 40% and 60% stearins (CSt1 and CSt2), blended with a hard fraction (PSt) from palm oil (10?90%) and its suitability as a plastic fat was studied.

Dry fractionation of coconut oil using 120 kg-scale crystallizer to produce concentrated medium chain triglycerides MURSALIN 1,2) , PURWIYATNO HARIYADI 2,3) , EKO HAR1 PURNOMO 2,3) , NURI.

Virgin Coconut Oil Machinery Gem Allied Industries Pvt. Ltd

- Usage: Coconut oil refinery morocco, edibe oil processing

- Type: Coconut oil refinery morocco

Production Capacity: 50TPD~100TPD - Voltage: according to capacity

Power(W): according to capacity - Dimension(L*W*H): 1200*400*900mm3

Certification: ISO9001 - Item: Coconut oil refinery morocco

Bleaching earth consumption: 5~50Kg/T oil - Deodorization loss consumption: ≤0.5%

Waste bleaching earth oil content: <35% - Description: batch refining, semi-continuous, full continuous

- Business type: manufacturer

material: Stainless steel & carbon black - Brand: QI'E

At Gemtech Projects LLP, we manufacture and supply high-quality Virgin Coconut Oil Machinery in India, guaranteeing standard performance and output levels. Our team of engineers has specialised knowledge and expertise in machinery designing implemented with the latest technology. Our integrated solutions come with built-in features and embedded.

Emulsion Fractionation of Coconut Oil: A New Fractionation Technology. Kesarin Chaleepa J. Ulrich. Chemistry. 2011. Fractional crystallization technologies are commonly used to modify the triglyceride compositions of fats in order to extend their utilization. Improvements in solid fat properties to stabilize fat…. Expand.

Dry fractionation of coconut oil by melt crystallization

- Usage: Coconut Oil

- Type: Coconut oil making machine

- Production Capacity: 150-250kg/h

- Model Number: 6YL-100 Coconut oil making machine

- Voltage: 380V

- Power(W): 7.5Kw

- Dimension(L*W*H): 1950x1300x1900

- Weight: 950 kg

- Certification: CE,BV & ISO9001

- Screw speed:

- Heater:

- staff requirement:

- space requirement:

- Package:

- Gear ratio:

- usage:

- features:

- Vacuum pump:

- Dimension: 1950x1300x1900

Thermal study of coconut oil. Coconut oil exhibits a single melting point at 24.83 ± 0.15 °C and a crystallization point at 10.3 ± 0.86 °C, respectively. It posses a solid fat content of 27.09% at 25 °C. The isothermal crystallization and remelting profile of coconut oil were studied by DSC within the temperature range between the melting.

Abstract. This work was aimed to study the solvent fraction of coconut oil (CNO). The fatty acid and triacylglycerol compositions, solid fat content (SFC) and the crystallization properties of CNO and its solid and liquid fractions obtained from fractionation at different conditions were investigated using various techniques. CNO was dissolved.

- How is coconut fractionation performed?

- The fractionation was carried out following the method described by Md Zaidul et al. (2006) with some modification. Approximately 20 g dried grated coconut was loaded into a 50 mL extraction vessel. Liquid carbon dioxide (purity of 99.9%) was pumped into the heated extraction cell.

- What is the melting behaviour of coconut oil fractions (F-CNO)?

- Melting behaviour of coconut oil fractions (F-CNO) A melting behaviour test was performed to determine the melting temperatures (Tonset, Tpeak, Tendset) of CNO fractions, (F1, F2, F3, F4), unfractionated CNO and commercial CB.

- Is layer melt crystallization effective in dry fractionation of coconut oil?

- 4. Conclusions Our results allow the conclusion that layer melt crystallization carried out by using the cold-finger apparatus is an effective technique in the dry fractionation of coconut oil.

- Why is the yield of coconut oil important in centrifugation?

- Yield of the coconut oil is used to optimize the parameters. For centrifugation speed, results showed that when increasing the speed, the coconut oil yield increases as well, reaching 9.27% when centrifuged for 15 min at 12,000 rpm. As for the centrifugation time, the longer the sample is centrifuged, the higher the yield of coconut oil is.

- Voltage: according to capacity