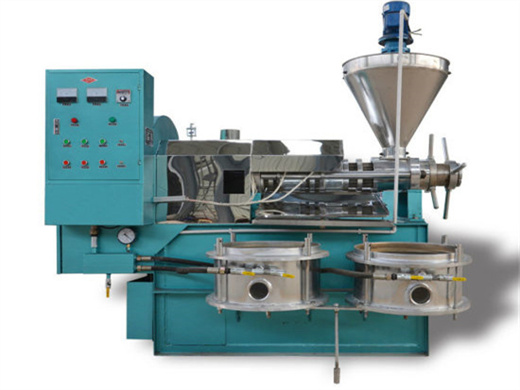

big using peanut oil extraction machine in tanzania

- Usage: Peanut and other

- Type: Vegetable Seed Oil Machine

- Production Capacity: 98%-100%

- Model Number: 6LD

- Voltage: 380

- Power(W): 5.5KW~15KW

- Dimension(L*W*H): 2200*1600*2150

- Weight: 780kg

- Certification: CE ISO

- Capacity of oil screw press with filter: 35kg-400kg/h

- Material: Stainless Steel SS304/316

- Residual oil rate: 5~7%

- Raw material: Peanut

- Advantage of oil screw press with filter: 36 Years for oil press machine

- Warranty period: 12 months

- Application range: Oil Production Line

- Feature of oil screw press with filter: High Oil Yield Efficiency

- Function of oil screw press with filter: Produce High

- Character: Screw Oil Pressing Machines

Hongde SCREW PRESS is a leading manufacturer of groundnut / peanut / earthnut oil mill plants. We have exported oil mill machinery and equipment for customers around the world. Our groundnut oil extraction machines are successfully running in India, Nigeria, Tanzania, Chad, Senegal, Cameroon, Ethiopia, Niger, Ghana, Sudan, Mali, Burkina Faso.

Groundnut Decorticator. Groundnut decorticator machine is used to remove the hard shell of peanuts and get red skin peanut kernels automatically. The shelled peanut kernel can be applied to the peanut oil production line. Groundnut decorticator is versatile in shelling not only peanuts but other oil seeds like almonds, sunflower seeds.

peanut oil press machine for sale/large peanut oil processing

- Usage: Edible oil, Edible Oil

- Production Capacity: High

- Model Number: Peanut processing equipment, Peanut processing equipment

- Voltage: Depend on Peanut processing equipment capacity

- Power(W): Depend on Peanut processing equipment capacity

- Dimension(L*W*H): Depend on Peanut processing equipment capacity, Depend on the capacity

- Weight: Depend on Peanut processing equipment capacity

- Certification: ISO9001

- Steam consumption: 450kg/T oil

- Waste bleaching earth oil content: Less than 35%

- Color: Based on Peanut processing equipment

- Use: Use Peanut processing equipment

- Residual oil in meal: Less than 1%

- Crude oil moisture and volatile matter: Less than 0.30%

- Item: Peanut processing equipment

Taizy provides a peanut roasting machine and other supporting equipment to help increase the oil yield and improve work efficiency. When roasting peanuts, stir-fry the peanut kernels until they reach eight maturities. Keep the temperature at about 130 degrees and the water content is about 1 to 2%.

The Manual Screw Press for Small-scale Oil Extraction, This book describes the Practical Action oil press manufacture and use, Oil Processing: Food Cycle Technology Source Book by UNIFEM, This book has a broader coverage. Small-scale Peanut Butter Processing in Tanzania Food Chain Journal Number 30 June 2002, ITDG.

Groundnut Oil Manufacturing Process With Flowchart - Hongde

- Usage: Peanut Oil, Cooking Oil

- Production Capacity: 1-100T/DAY

- Voltage: 380V/440V

- Dimension(L*W*H): 3050 * 3050 * 2150

- Weight: 0 KG

- Warranty: One Year warranty against manufacturer defect.

- Core Components: Other

- Oil type: Peanut Oil

- After Warranty Service: Field maintenance and repair service

- Certification: ISO

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

The way of steaming, the effect is very good. In addition, when the press is pressed, the setting of the temperature of the oil press is also very important. If it is to make the oil taste strong, the temperature can be a little higher. If it is for the sake of good oil quality, it is recommended that the temperature be set at about 140 degrees.

An Overview of Groundnut Oil Extraction Technologies

- Usage: Peanut Oil;

- Production Capacity: 100%, 99%

- Model Number: HT-POM

- Voltage: 380V

- Power(W): less than 85KW

- Dimension(L*W*H): according to the specification

- Weight: about 35ton

- Certification: ISO9001,CE,BV

- type: Peanut oil press equipment

- Raw materials: Peanut, cutton seed

- Material of equipment: stainless steel and carbon steel

- including: machines,installation,tech consulting after sales

- operattion: automatic and safe

- Capacity: 1T to 500T

- color: according to your need

- Warranty period: 1 year

Abstract and Figures. Groundnut oil extraction involves removing oil content of the groundnut seed. Study conducted in Northern Nigeria revealed that 75% of the rural women engaged in groundnut.

This groundnut oil processing machine set is fully adopted mechanical driven, it connects each oil production machinery together to extract oil with higher oil yield (including, cooker, conveyor and multi-function oil expeller with filter). Here is the details and features of the groundnut / peanut oil production machine: Big pressing force in the chamber, making high oil output; Easier to.

Groundnut Oil Extractor | Peanut Oil Expeller

- Usage: Oil Press

- Type: Oil Press Machine

- Production Capacity: 5TPD

- Voltage: 380v

- Dimension(L*W*H): 880*440*770mm, 880*440*770mm

- Weight: 140 KG

- Core Components: Gear, Bearing, Engine

- Oil type: Peanut Oil

- Product name: Peanut oil cold press machine

- Modle: 6YL-68

- Productivity: 800-1000kg/24h

- Power(kw): 5.5kw

- Function: Oil Pressing

- Advantage: High Oil Yield Etc

- Used for: Pressing Oil Seeds

- MOQ: 1PC

- Keywords: Peanut oil cold press machine

High oil output rate. The oil yield of a groundnut oil extractor can reach about 50%. The dry cake residue rate is less than or equal to 8%. High efficiency. Our peanut oil expeller can process 500 kg of raw materials per hour. And only one person can operate the machine. Wide range of applications.

Production steps of peanut oil extraction. Peanut Shelling Machine. 1, Oil extraction of peanuts first to go through the shell, select the sprouted and bad, before pressing peanuts can manually peel off peanut shells, but this is more time-consuming, generally only when the amount of family oil extraction is small, only in advance of shelling.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- How is peanut oil extracted by mechanical pressing?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

- How to choose the best peanut oil extraction machine?

- What’s more, the amount of slag taken by the oil press has a direct effect on the quality of the oil. Choosing LONGER peanut oil extraction machine is a very good choice. An advanced oil extraction machine, plus the right press, can produce high quality peanut oil.

- What are the different methods of peanut oil production?

- Currently, there are two main methods of peanut oil production: a) Traditional Pressing (Mechanical Method): In this method, a peanut oil press is utilized to squeeze out the oil from the peanuts. The mechanical force applied through pressing allows the oil to be extracted effectively.