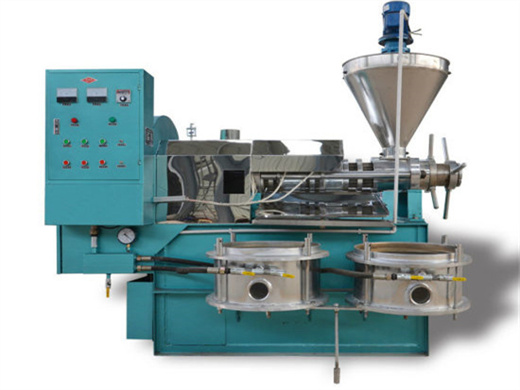

big factory peanut oil solvent extraction machine in rwanda

- Usage: Squeezing and extraction of oil and agricultural products, Squeezing and extraction of oil and agricultural products

- Type: Cold & Hot Pressing Machine, Cold & Hot Pressing Machine

- Production Capacity: ≥98%

- Voltage: 380V/50HZ

- Dimension(L*W*H): 5000*2580*2700 mm

- Weight: 8000 KG, 8000kg

- Core Components: Other, Gear, Gearbox, frame, Squeezing part, Feeding system

- Oil type: Peanut Oil, Safflower seed Oil, Peanut oil

- Product name: seed oil press

- Maximum capacity: 20-25T/D

- Power: 45KW

- Residual oil rate: 6-9%

- OEM: Manufacturer with self-support import and export rights

- Item: Essentials Oil Steam Distillation Equipment

- After Warranty Service: Video technical support

Hongde SCREW PRESS is a leading manufacturer of groundnut / peanut / earthnut oil mill plants. We have exported oil mill machinery and equipment for customers around the world. Our groundnut oil extraction machines are successfully running in India, Nigeria, Tanzania, Chad, Senegal, Cameroon, Ethiopia, Niger, Ghana, Sudan, Mali, Burkina Faso.

Groundnut is a very common oil bearing material, so the technology of extracting peanut oil is relatively mature. Hongde GROUP is the largest groundnut oil extraction machine manufacturer and supplier in India. We are focused on providing the most advanced oil processing machines to help our customers reduce costs and improve oil production.

Groundnut Oil Manufacturing Process With Flowchart - Hongde

- Usage: Peanut oil extraction machine price

- Type: Peanut oil extraction machine price

Production Capacity: 50-300TPD - Voltage: 380V/50HZ

Power(W): according to capacity - Dimension(L*W*H): 1200*400*900mm3

Certification: ISO CE BV - Name: Peanut oil extraction machine price

Warranty: 1 year - Application: oil extracted

- Residual oil in meal: less than 1%

Power consumption: not more than 15KWh/T - Solvent consumption: less than 2kg/t

- Crude oil moisture and volatile matter: ≤ 0.30%

Finished meal moisture: ≤ 13% (adjustable) - Residual solvent in finished meal: ≤300PPM (qualified detonated experiment)

- Steam consumption: ≤ 280KG/T (0.8MPa)

Groundnut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into.

Hexane and ethanol as peanut oil solvents. Absolute ethanol is a better solvent for extracting peanut grits than 95% ethanol, with hexane intermediate in its action.

What is the basic principle of peanut oil solvent extraction?

- Usage: Peanut OIL, for rosehip, Peanut, etc

- Type: Cooking Oil Press Machine

- Production Capacity: 13.50kg/hour, 13.50kg/hour

- Voltage: 220v/50hz, 220v/50hz

- Dimension(L*W*H): 860*650*1200mm, 1000*600*800mm

- Weight: 350 KG, 350KG

- Core Components: Spare parts

- Oil type: Peanut Oil

- Life time: 15 years

- Certification: CE,ISO

- After Warranty Service: Online support

- After-sales Service Provided: Online support

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

The peanut oil solvent extraction plant is designed to extract oil directly from oil seed containing less than 20% oil like soyabean after flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm kernel, canola, copra, castor and variety of other materials.

Peanuts Solvent Extraction Plant - Oil Mill Machinery

- Usage: 100TD mustard oil refining machinery

- Type: 100TD mustard oil refining machinery

- Production Capacity: 100tpd 100TD mustard oil refining machinery

- Model Number: Jinxin 100TD mustard oil refining machinery

- Voltage: 380v or According to the local voltage

- Power(W): According to the capacity of 100TD mustard oil refining machinery

- Dimension(L*W*H): 430*230*350 of 100TD mustard oil refining machinery

- Weight: 1050 KG of 100TD mustard oil refining machinery

- Certification: ISO9001 100TD mustard oil refining machinery

- After-sales Service Provided: Engineers available to service machinery overseas, Engineers available to service machinery overseas

- Name: 100TD mustard oil refining machinery

- Automatic grade: Full automatic

- Residual oil in meal: Less than 1%

- Material: Stainless steel

- Crude oil moisture and volatile matter: Less than 0.30%

- Consumption: Low

- Oil grade: 1st,2nd,3rd

- Port: Qingdao

The solvent extraction method recovers almost all the oils and leaves behind only 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant etc. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%.

Groundnut Oil Press Peanut Oil Extraction Plant Section Introduction: We can provide the equipments to process different capacity of peanut groundnut They bring unrivalled experience to bear in producing accurate drawings detailing foundation loadings, building dimensions and overall plant layout designs, tailor made to

Peanut Oil Press Machine - Professional Supplier Of Oil Mill

- Usage: Peanut Oil

- Type: whole Peanut kernel expeller malaysia

- Production Capacity: 100%

- Model Number: 1st series Doing Peanut kernel expeller malaysia

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Certification: CE and ISO

- Raw material: Peanut

- Product: to make crude Peanut oil or refined Peanut oil

- Solvent name: n-hexane

- Capacity: from 5T to 2000T Peanut kernel expeller malaysia

- Oil content in Peanut: about 40%

- Oil residues: less than 1%

- Function: getting Peanut oil

- Manufacturing experience: 19 years experience in edible oil field

- Material of equipment: stainless steel and carbon steel

3. Flaking Process: After crush and peel,we need to flake the crushed peanut , which make the cell wall of peanut broken . And we flake the peanut to 0.55 mm thickness. Then it is useful for the oil extracting. 4. Cooking Process: After the flaker,we need to cook the flaked peanut , control the moisture at 5-7% , the temperature is 110-115degree .

Henan Glory Company specializes in peanut oil processing machine for 10+ years, customized 1-1000tpd peanut oil extraction machine, offering real-time quotes,great after-sales service. WhatsApp/Tel: 008613526627860 get a free quotation

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- Where are groundnut oil extraction machines used?

- Our groundnut oil extraction machines are successfully running in India, Nigeria, Tanzania, Chad, Senegal, Cameroon, Ethiopia, Niger, Ghana, Sudan, Mali, Burkina Faso & many other countries. We undertake turnkey project solutions for the complete groundnut / peanut / earthnut Oil Mill Plant.

- Who are the best coconut oil extraction machine manufacturers in India?

- Micro Fab Engineers is the best coconut oil extraction machine manufacturers in India at a reasonable cost. We a team of professionals are working with the latest technology and using a high- grade components to ensure high quality. Are you wondering about the coconut oil manufacturing machine price in India?

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- Voltage: 380V/50HZ