full palm kernel oil expeller machine 220v in malawi

- Feature: Anti-wrinkle, QUICK DRY, Compressed, Anti-pilling, Breathable, Sustainable, Anti-Shrink, EL Flashing, Contrast Trim

- Collar: O-Neck

- Technics: Printed

- Sleeve Style: Short sleeve

- Gender: Men

- Pattern Type: Solid

- Style: Casual

- Fabric Type: knitted

- 7 days sample order lead time: Support

- Weaving method: knitted

- Material: 100 Palm

- Design: ODM Designs

- Printing: Cutsom Printed

- Quality: High-quality

- Logo: OEM Custom Logo

- Label: Size Label

- MOQ: 1pc

- Payment: Paypal.western Union.TT. Trade Assurance

- Shipping: DHL\EMS\UPS\FEDEX\by Sea\by Air

- Size: s-xxxl

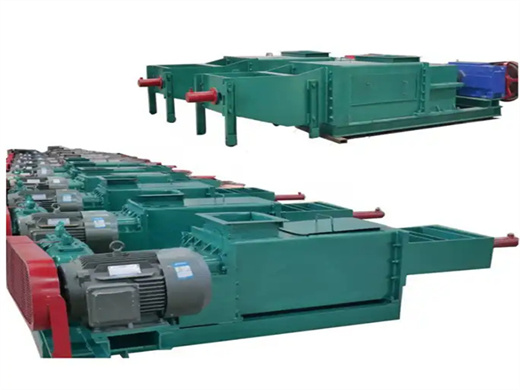

Specially designed and manufactured for maximum oil extraction from palm kernel. Minimal residual oil content in the second press cake. Independent gearbox system reduces noise level, consume less power and ensure zero contamination of mineral oil with edible oil. Alloy steel with ultrasonically tested screw shaft with heavy-duty branded bearings.

Palm Kernel Oil Expellers / Palm Kernel Screw Press are screw type machines that presses oil seeds in order to extract the oil in the seeds. These seeds are fed from one side of the press, which then enters into the pressing chamber. The palm-kernel machines uses pressure and friction from the screw drives to move as well as to compress the oil.

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

- Usage: Palm oil grinding machine

- Type: Palm oil grinding machine

- Production Capacity: 80-600KG/H

- Model Number: 6YL Palm oil extraction machine

- Voltage: 110V,280V,380V,440V

- Power(W): according to the capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- name: Palm oil grinding machine

- texture: carbon steel and stainless steel

- man power: 1 person a shif

- motors: special for Palm oil grinding machine

- package: wooden cases special for Palm oil producing machine

- land area: according to the capacity

- color: according to the customer

- materials: Palm,all edible s material

- end products: edible oil, oil cake for animal feed

- filter: with vaccum filters

The full set of Palm Kernel Oil (PKO) Processing Machines include Husker, Crusher, Cooker, Oil Press Expeller, Oil Filter, Oil Refinery Machine, etc.. Oil Capacity: 1~1000 Tons/Day. Oil Yield: >45%. Oil Residual in Cake:

The choke mechanism Machine Capacity: The theoretical capacity of the expeller was determined as 280.6kg/hr using a modified form of the equation given by (Adetola et al (2014) as: Q c = 60 π 4.

Palm Kernel Oil Manufacturing Process

- Usage: Palm Palm Oil processing

- Type: Palm & Palm Kernel Oil Pressing Machine

- Automatic Grade: Automatic

- Voltage: 380/440V

- Dimension(L*W*H): Customized

- Weight: 10000 KG

- Marketing Type: High quality cooking Oil factory

- Warranty of core components: 1 Year

- Core Components: Motor, Pump, Engine

- Oil type: Palm Oil, Palm Kernel Oil

- Certificate: CE/ISO9001/2000

- Customized: Accept

- Supplier: China manufacturer,factory

- Machine capacity: 5-5000T/D and accept customize

- Application: Palm Oil Production plant

- Raw material: Palm,corn gram,Palm Kernel,Palm

- Machine Material: 304 stainless steel,Iron,steel

- After-sales Service Provided: Online Video Technical Support,Engineer's on-site guidance

- Product name: cooking Oil making machine

- Keyword: Palm Oil production line

The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing. Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing.

Palm kernel oil is a type of vegetable oil which is high in saturated fat and Omega 6, presenting serious health concerns. It is derived from the palm kernel, grown on the African oil palm tree. Oil palms originated in West Africa. Palm kernel oil is an important part of the oil market in the world, at present, it is more than 30% in the oil.

Design and Fabrication of a Palm Kernel Oil Expeller Machine

- Usage: Palm oil extraction plant

- Type: Palm oil extraction plant

- Production Capacity: 1-500T/D

- Model Number: YY88

- Voltage: 380V-415V

- Power(W): depend on the mode of the Palm Oil Machine

- Dimension(L*W*H): depend on the mode of the Palm Oil Machine

- Weight: depend on the mode of the Palm Oil Machine

- item: beans oil extract machine

- production process: pretreatment,extraction,refining

- Raw material: Palm, Palm Kernel

- Waste Bleaching Earth Oil Content: 25% to 35 %

- Electric Consumption: 28Kwh/T Oil

- Soften Water: 150Kg/T Oil

- Phosphoric Acid: 2~3 kg/T Oil

- Bleaching Earth Consumption: 80-500KG/T Oil

- Supplier Type: Palm oil extraction plant

- Steel material: Stainless Or carbon steel

The aim of this work is to design and fabricate an effective palm kernel oil expeller machine. A high torque and low rotational speed palm kernel oil expeller machine was developed by introducing an adjustable choke mechanism that permits adjustment of the back pressure to regulate the thickness and dryness of the pressed cake passing through the clearance between the barrel and the screw shaft.

The Super Duo Series Expeller is ideal for capacities of 10-30 tons per day on difficult-to-process specialty materials such as corn germ, coffee beans, sesame seed, and grapeseed. The unique dual-pressing design allows for the lowest possible residual oil levels in a single pass. Speak to a Representative.

Malaysia Palm Kernel Expeller | Mills Manufacturer

- Usage: Palm oil

- Type: Oil Pressing Machine, Palm oil processing equipment

Production Capacity: 250-400 kg/h - Voltage: According to customer demand

Power(W): 21 KW - Dimension(L*W*H): 2200*1600*2150

- Weight: 1300kg

Color: White, green Production Raw material: Palm, Palm Kernel - Work principle: Mechanical extruding

- Warranty period: One year

English manual: Yes - Factory visiting: Yes

Muar Ban Lee Group is a world-leading palm kernel expeller manufacturer specializing in palm oil machinery and oil seed crushing machinery. We provide "One Stop Service" in setting up Palm Kernel Crushing Plants from Plant Design and Fabrication to Installation and Commissionning. With our in-depth knowledge of the industry, our expertise and.

The New EK-300-K is designed and built for profitability optimization. MBL devoted monumental efforts in R&D of the EK-300-K. R&D started in 2013 headed by professional engineer with a team of six experienced technical engineers through actual oil extraction test. In total, MBL accumulated 18 months or 9,000 hours of in house field test on the.

- What is a palm kernel expeller machine?

- Palm kernel expeller machines are designed using the most advanced technology by experienced professionals. These machines make it easy to extract palm oil and palm kernel cake. Palm kernel cake is a product that is obtained when palm kernel is crushed to expel oil. This is a mechanical process that is important in the production of animal feed.

- What are the different types of oil expeller machines?

- MBL is a manufacturer of a variety of such oil expeller machines. Our product range includes many kinds of oil expeller machines including copra oil expellers, jatropha oil expellers and palm kernel expellers. Palm Kernel Oil Expellers / Palm Kernel Screw Press are screw type machines that presses oil seeds in order to extract the oil in the seeds.

- What is MBL palm kernel oil expeller / palm kernel screw press?

- MBL palm kernel oil expellers / palm kernel screw press ensure efficient extraction of oils by producing the most yield from each press. Our trademark worm collar/worm screw ensures longer lifespan and reduction in maintenance cost. Extraction of Oil: Oil can be expelled from seeds in normal screw type oil expeller.

- How does a palm kernel machine work?

- The machines break down the palm kernels into small fragments before grinding them. Once the kernels are ground, the machines screw presses them to expel oil. Some of the machines are designed to cook kernels. The expeller machines can also crush the kernels without going through any pre-treatment process.

- Voltage: According to customer demand