palm kernel oil pressing oil mill machine in lusaka

- Usage: Small Scale Oil Mill

- Type: Oil Pressing Machine

Production Capacity: 98%-100% - Voltage: 380

Power(W): 5.5KW~15KW - Dimension(L*W*H): 2200*1600*2150

- Weight: 780kg

Capacity of cold pressed Palm oil: 35kg-400kg/h Material of cold pressed Palm oil: Stainless Steel SS304/316 - Residual oil rate: 5~7%

- Raw material: Palm, Palm Kernel

- Warranty period: 12 months

- Application range: Oil Production Line

Feature of cold pressed Palm oil: High Oil Yield Efficiency - Function of cold pressed Palm oil: Produce High

- Character: Screw Oil Pressing Machines

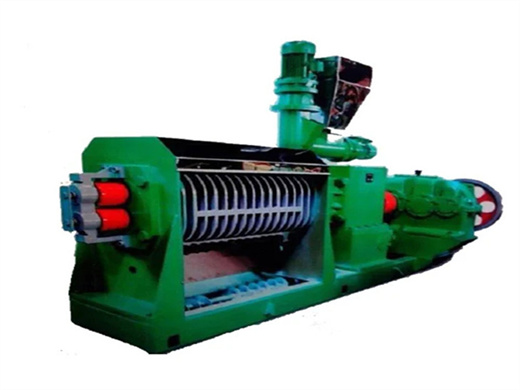

Palm Kernel Oil Mill Introduction. Automatic double-shaft palm kernel oil mill can squeeze out most of the oil from fresh palm kernels by the high mechanical pressure. Palm kernel oil extraction machine has a large processing capacity and high oil yield which is special for crushing palm kernels, and its service life is three times higher than.

The digester is like a big blender and has a central shaft with arms that rotate and mesh up the fruit. This action breaks up the oil cells and conditions the fibre for pressing. This process involves the crushing of the fruits and warming the pulp before oil extraction is done. Warming is important in order to maximize oil extraction.

small scale edible oil refining technology for zambia

- Usage: Cooking Oil

- Production Capacity: 3.5-50kg/h

- Voltage: 820w

- Dimension(L*W*H): 430*290*210

- Weight: 7100kg

- Core Components: Motor, Other, Bearing

- Oil type: Palm Oil

- Raw material: Palm

- Product name: Oil Press Machine

- Function: Making Edible Oil

- Application: Edible Oil Production

- Name: Home Oil Pressing Machine

3, 500-2000T/D large-scale cooking oil pretreatment & pre-press production line Oilseeds pretreatment and pre-pressing machine Palm fruit /palm kernel oil processing machine; 1-2-3-5TPH small palm oil processing machine 15-30-45-60-80-120TPH

The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing. Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing.

Palm oil press machine | FFB oil press | Palm oil mill plant

- CNC or Not: CNC, CNC

- Machine Type: Punching Machine

- Slide Stroke (mm): 180-280

- Power Source: Mechanical, Mechanical

- Voltage: 220-380V, 380V/50HZ

- Dimension(L*W*H): 7100*3500*3600

- Motor Power (kW): 15

- Model Number: SEAC-80AS-5

- Weight (T): 11.8

- Warranty of core components: 2 years

- Core Components: PLC

- After-sales Service Provided: after-sales service

- Weight: 11800KG

- Certification: CE ISO

- Advantage: High Efficiency

- PLC: Mitsubishi Japan

- Motor: SIEMENS

- After Warranty Service: Video technical support

Palm Oil Press Station: Separate palm fruit and kernel, and palm oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Palm fruits through elevator and conveyors, enters into upper steaming boiler of oil.

After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts. In palm kernel recovery plant, the nuts and fiber are separated by physical means. The nuts are sent to palm kernel crushing and solvent extraction plant to make palm kernel oil, while the fiber is used as biomass fuel in boiler on-site.

A study of palm oil mill processing and environmental

- Type: Centrifuge

- Product Type: Tubular Centrifuge

- Marketing Type: Ordinary Product

- Warranty of core components: 1 Year

- Core Components: PLC, Engine, Bearing, Motor, Gear

- Voltage: 380V/415V/220V Customizable

- Power: 2.2kw

- Weight: 400

- Dimension(L*W*H): 800*700*1400mm

- Application: Palm oil

- Function: separate oil from milk

- Operation: manual discharge

- Material: carbon steel or stainless steel

- Name: Palm oil extractor

- Machine type: Centrifugal Solid- -Liquid-Liquid Separator

- Description: VCO extraction

- Item: GF105

- Keyword: Liquid Extraction Machine

- Product name: Tubular Centrifuge Separator

PDF | On Apr 8, 2019, Azam Akhbari and others published A study of palm oil mill processing and environmental assessment of palm oil mill effluent treatment | Find, read and cite all the research.

KERNEL RECOVERY STATION EQUIPMENT LIST: 1.Nut Auger conveyor 2.Destoner Column c/w Fan,Ducting and Airlock 3.Nut Grading Drum 4.Nut Hopper c/w structure 5.Nut Vibrating Feeder 6.Super Craker (Ripple Mill) 7.Steel Support,Maintained Platform 8.Cracked Mixture Conveyor 9.Cracked Mixture Elevator 10.Winnowing System No.1&2Cyclone&Ducting 11.

Combination Digester And Hydraulic Press Systems

- Usage: Palm OilPalm OilPalm Oil

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: 150-200KG/H,3.5-5T/24H

- Voltage: 380V/220V

- Dimension(L*W*H): 1900*1300*2000mm

- Weight: 910 KG

- Marketing Type: Ordinary Product

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other

- After-sales Service Provided: Engineers available to service machinery overseas

- pressing cage heating power: 0.8kw-220v

- Filter air compressor power: 2.2kw-220v

- pressing power: (7.5-11kw)-6p

- Main shaft heating power: 1.8kw-220v

- Raw material: Palm, Palm Kernel

- Application: Palm Oil Production

- machine material: Carbol Steel

TechnoServe Inc. brought the digester, hydraulic press and spindle press into a rural community together with the business management training to create small-scale palm oil processing enterprises. However there were engineering problems with plant layout and matching the throughput of machine components.

The hydrocyclone separates palm kernel from shell particles by using of their proportion. The equipment list of palm kernel recovery station: 1.Cake Breaker Conveyor c/w Maintenance Platform&Supports 2. Nut Polishing Drum 3.Depericarper Column c/w Supports 4.Fibre Ducting’s&Air Ducting 5.

- Voltage: 380