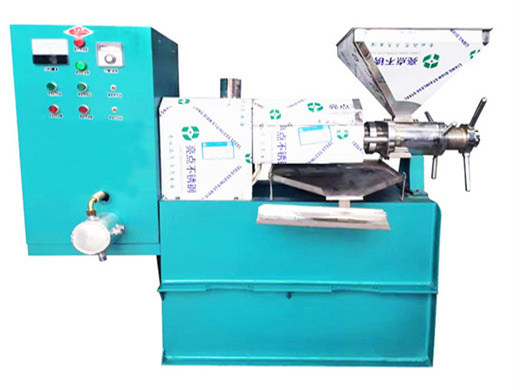

crude coconut oil procissing machine plant in uganda

- Usage: Coconut Oil Production Factory

- Type: Oil Pressing Machine

Production Capacity: 45 sets per year - Voltage: 380V/440V

Power(W): 30KW - Dimension(L*W*H): 1200*2800*1200mm

- Weight: 500TON

Certification: CE/ISO9001/BV - usage: Coconut Oil Production Factory

oil clolor: yellow - advantage: save energy

- bleaching earth consumption: 5-50kg/t oil

decolor function: remove the bad color - deodor function: remove the bad smell

- Name: Best quality cooking oil making refinery machine

Function: Making Edible Oil - Material: Coconut

- Advantage: good quality

Here are the important coconut oil manufacturing plant machines you need to start an oil manufacturing business: Boiler. Copra Cutter. Copra Dryer. Cooker / Kettle. Copra Oil Expeller Machines. Crude coconut oil storage tanks. Oil Filter Press Machines. Bucket Elevator.

Virgin coconut oil is a useful substance in our daily life. It contains a high percentage of lauric acid which has many health benefits. The current industry has developed several methods to extract the oil out from the coconut fruit. This review paper aims to highlight several common extraction processes used in modern industries that includes cold extraction, hot extraction, low-pressure.

Coconut Oil Processing Machine Manufacturer - Copra Oil Machine

- Usage: Coconut oil

- Type: whole

- Production Capacity: 100%

- Model Number: 1st series YL Coconut oil refinery plant

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Certification: CE and ISO

- Raw material: Coconut

- Product: to make crude Coconut oil or refined Coconut oil

- Solvent name: n-hexane

- Capacity: from 5T to 2000T Coconut oil refinery plant

- Oil content in Coconut: about 44-55%

- Oil residues: less than 1%

- Function: getting Coconut oil and refining it

- Manufacturing experience: 19 years experience in edible oil field

- Material of equipment: stainless steel and carbon steel

Hongde 1500. 45 150 Tonnes per 24 Hours. 3-Phase 170 H.P. 5500 MM. 1380 MM. 1980 MM. Are you looking for the most suitable and cost effective Coconut Oil Extraction Machine or Coconut Oil Extraction Plant to start your own Coconut Oil Manufacturing Business, then you are in the right place. Hongde is the best and reliable manufacturer.

Follow-on Zoom calls with the local team, including experts in coconut agriculture, allowed me to further expand my understanding of the challenges faced by coconut farmers. Once a foundational understanding was gained regarding the structure of the coconut economy, activities were focused primarily on gaining a clearer view on the current.

Copra Oil Mill Machine for 20TPD Coconut Oil Production Plant

- Usage: Coconut Oil

- Type: extraction machine, Coconut oil extraction machine

- Production Capacity: 10-5000T/D

- Model Number: DT-10099

- Voltage: 220V/380V/440V

- Power: 2.2KW

- Dimension(L*W*H): 1910*550*765 mm

- Weight: 420 KG

- Certification: ISO9001

- Raw material: Coconut

- Function: Vegetable Oil

- Application: Coconut,etc.

20TPD Copra Oil Mill Plant in Philippines. This is one of our project in Philippine a medium scale copra oil mill, including 20TPD oil extraction line and 10TPD oil refinery line. The daily capacity is processing 20 tons of copra (desiccated coconut) and get 10 tons of refined coconut oil. It is designed for manufacturing edible coconut oil.

The Codex Standards for Aqueous coconut products states that coconut milk should contain at least 10% fat, 2.7% non-fat solids, and 12.7-25.3% total solids. While coconut cream should contain at least 20% fat, 5.4% non-fat solids and 25.4-37.3% fat (Table 6.1). Table 6.1. Classification of coconut milk and cream.

Breaking Down the Basics of Copra Oil Processing

- Usage: oil cold press machine

- Type: nut oil press machine

- Production Capacity: 30t/d

- Model Number: OC30, CC60

- Voltage: 380V

- Power(W): 15-30KW

- Dimension(L*W*H): 1200*400*900mm3

- Certification: ISO9001/BV/CE

- Use: Used for oil extraction centrifuge

- Moisture: 3%

- deodorizaiton time: about 30min

- oil content: 60%-70%

- residual oil in cake: 2%

- oil flow out time: 0.5min

- original: china

- capacity: 1-50t/d

- press type: oil extraction machine

Processing copra oil. Traditionally, processors feed flaked copra into stacked cooking and drying vessels, which reduce the moisture levels down to about 3 or 4% by weight. Then, dried flakes are crushed in a screw press expeller to separate the copra oil from the solid meal. Containing up to 70% oil by weight, coconuts have the highest oil.

15.3.3 Coconut oil. Coconut oil is very popular in recent years in food and skin products [30]. It is derived from the white lining within the shell, of mature coconuts [30]. Coconut oil contains high levels of lauric acid, which has been shown to have antimicrobial and anti?inflammatory effects [30].

Process flow chart for the production of Virgin Coconut Oil

- Usage: Edible oil

- Type: Oil Extraction Machine

- Production Capacity: 93%

- Voltage: 380V/Others

- Dimension(L*W*H): 2100X620X770mm

- Weight: 530kgs

- Core Components: Motor, Pump, Gear, Bearing, Engine, Gearbox

- Oil type: Coconut Oil

- Raw material: Coconut

- Application: Edible Oil Production

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: South Africa

- After-sales Service Provided: Video technical support, Online support

A total of 17 genera with relative abundances greater than 0.01% constitute the core microbiome of the two processing lines and account for 74% to 97% of the microbial abundance in all coconut.

Our units sweeten sour crudes through a series of separation stages where H 2 S and CO 2 are absorbed by ethanolamine, leaving sweet gas in the top of an absorber and separating H 2 S and water for disposal. Joule designs and engineers crude oil processing products to help maximize flexibility and optimize production.

- What is the cost effective machinery for coconut oil extraction?

- For small or medium size coconut oil mill plant, the screw coconut oil expeller is the cost effective machinery in the from these aspects, including oil yield, investment cost, operation and maintenance. Coconut oil expeller machine is now the most commonly used machinery for coconut oil extraction.

- Who are the best coconut oil extraction machine manufacturers in India?

- Micro Fab Engineers is the best coconut oil extraction machine manufacturers in India at a reasonable cost. We a team of professionals are working with the latest technology and using a high- grade components to ensure high quality. Are you wondering about the coconut oil manufacturing machine price in India?

- What is the manufacturing process of coconut oil?

- The manufacturing process of coconut oil is from the white pulp of the coconut, which is the base from which the oil is extracted. With regard to extraction, a distinction must be made between virgin coconut oil and industrial coconut oil.

- Who is the manufacturer of coconut husk processing machinery?

- M.M Engineering are leading Manufacturers, Exporters and Suppliers of a wide ranging variety of Coconut Husk processing machinery, Coir Extraction products & Processing. Since our inception in the year 1990. Read More Infrastructure To keep up with the emerging Worldwide marketdemand for Coconut Processing Machinery Coir Extraction products.

- Voltage: 380V/440V