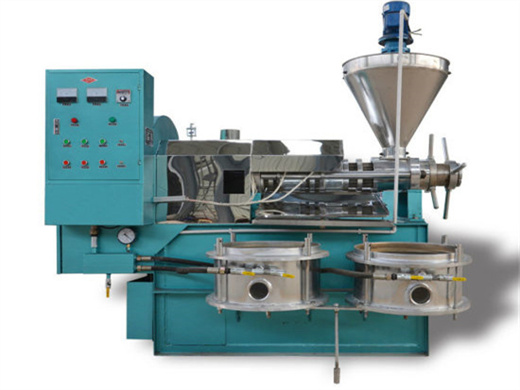

hot pressed peanut oil extraction machine in lesotho

- Usage: Oil press

- Type: Oil press

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): 7.5kw

- Dimension(L*W*H): 1200*400*900mm3

- Weight: According to the Peanut Press capacity

- Certification: ISO9001

- Item: Peanut Screw Oil Presser

- Material: Stainless Steel 304

- Function: Oil press

- Advantage: Energy Saving

- Feature: High output

- Performance: Excellent

- Color: As your requirement

- Application: Peanut,etc.

- Turnkey Project: Yes

The conditioned peanut kernels are transported by a conveyor to the twin-screw press for cold pressing; the cold-pressed crude oil and cold-pressed peanut meal with low denaturation will be obtained. After the cold-pressed crude oil is filtered with frame filter, product oil is obtained, which will be packaged by a filling machine to form cold-pressed peanut oil products ( Fig. 3.8 ).

The way of steaming, the effect is very good. In addition, when the press is pressed, the setting of the temperature of the oil press is also very important. If it is to make the oil taste strong, the temperature can be a little higher. If it is for the sake of good oil quality, it is recommended that the temperature be set at about 140 degrees.

Peanut Oil Press-- Integrated Screw Oil Press for Both Cold Pressing & Hot Pressing

- Usage: Peanut Oil, All kinds of oil seeds

- Production Capacity: 50-800kg

- Voltage: 220v Or 110V

- Dimension(L*W*H): 53*27*38

- Weight: 18 KG

- Core Components: Motor, Bearing, Engine

- Oil type: Peanut Oil

- Product name: Screw Press Oil Expeller

- Advantage: Energy Saving Low Residual

- Feature: Multifunction High Efficient

- Application range: Food Edible Oil Produce Line

Cold Pressing Peanut Oil: Integrated Screw Oil Press Advantages. 1. A wide range of application. It can press more than 20 kinds of oil plant seeds, such as soybean, peanut, sesame, rapeseed, sunflower, olive, palm, peanut and flax seed, etc. 2. High oil yield and purer oil. The equipped vacuum filter is used to remove residue to ensure the.

Our country has a vast territory, a large number of crops, a variety of fruits, vegetables, and a variety of oil crops.So what is our usual use of vegetable oil?Let’s know which materials are suitable for hot press equipment. When the raw materials are suitable for cold pressing, we should first understand the difference between the hot press and the cold press of the oil press.

Bioactive Phytochemicals from Peanut Oil Processing By-products

- Voltage: 380V

- Power: 3KW,380V,50/60Hz

- Dimension(L*W*H): (L)335*(W)73*(H)163CM

- Weight: 900 KG

- Application fields: Snack food factory, Commercial catering, Meat processing plants, Frozen food Factory, Dairy products factory, Cooking oil factory, Fruit processing plant, Flour mill, Beverage Factory, Cannery, Vegetable processing plant, Seasoning plant, Bakery, Winery

- Machinery Function: Multifunctional

- Raw material: Water, Fruit, Nuts, Wheat, Peanut, Milk, Vegetables, Flour, Peanut, Egg, Sugar

- Output product name: Toast,Baguette,Breadsticks,Burger Buns Bread

- Core Components: Bearing, Motor, Pump, Gear, PLC, Gearbox, Pressure vessel, Engine

- Power Source: Gas/Electric

- Application: Baguette Processing Machine

- Usage: French Bread Making Machine

- Type: Automatic Forming Machine

- Function: Multifunctional Bread Production Line

- Keyword: Automatic Bread Machine

- Suitable for: French Long Bread Baguette Bread

- Material: Food Grade Stainless Steel

- Feature: High Capacity

- Advantage: High Speed Stability

- Certifications: CE and ISO90001

2 Chemical Composition and Bioactive Compounds of Extracts from Peanut Oil-Processing By-Products. The edible kernel comprised about 68?72% of the peanut, while the balance 28?32% is the peanut hull [ 8 ]. Peanut kernel’s average thickness, width, and length are 6.9 mm, 3.6 mm, and 8.5 mm, respectively [ 9 ].

Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine applies pressure on the peanuts, resulting in oil being extracted.

Peanut oil press machine | peanut oil extraction machine - Oil press machine, Hydraulic press oil, Oil Refinery Machine

- Usage: Peanut oil

- Type: Cold & Hot Pressing Machine

Production Capacity: 10-100TPD - Voltage: 220V/380V

Power(W): Standard - Dimension(L*W*H): Standard

- Weight: Standard

Certification: CE ISO9001 - Name: Virgin Refined oil press machine/ Peanut oil refining plant for sale

Raw material: Peanut - Advantage: Simple Operation

Feature: High Output High oil yield. The peanut oil press machine is clean in a single press, with a high oil yield and it saves labor and time. It can realize multi-stage propulsion in a single press, and the oil yield can increase by 10-30%. Compared with the old peanut extraction equipment, the normal oil yield can be 2 to 3 percentage points higher.

The 6YL-100A peanut oil extraction machine is an integrated oil press machine suitable for both cold and hot pressing. It is capable of extracting oil from various oil-bearing crops like rapeseed, cotton seed, sesame seed, soybeans, sunflowers, jatropha, linseed, and other vegetable oil plants, making it a versatile machine for oil extraction.

Peanut proteins: Extraction, modifications, and applications: A comprehensive review

- Usage: Cocoa,Peanut,Peanut

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Dimension(L*W*H): depend on model

- Weight: KG

- Core Components: Motor

- Oil type: Peanut Oil

- Product name: Hydraulic oil pressing machine

- Material: Stainless steel

- Color: Formulate

- Operation Manual Book: English & Chinese

- Price: high quality with factory price

- Advantage: Energy Saving,easy operation

- Raw material: Peanut ,cocoa butter etc.

- Name: Oil Press Machine

- Function: Oil Pressing

Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent (n-hexane) extraction [29]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

In this study, peanut oil was prepared by cold pressing (temperature under 60 C), hot pressing (temperature above 105 C), and enzyme-assisted aqueous extraction technology. Influences of an extraction technology on the oil fatty acid composition and the content of minor bioactive compounds, including tocopherols, polyphenols, and squalene, were investigated in detail.

- What is peanut oil processing technology?

- This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- What is the capacity of cold press oil extraction machine?

- Semi automatic cold press oil extract machine, capacity: 1-5… Cold press oil extraction machine, capacity: 10-12 kg/hr, si… Mini expeller multi seed oil extraction machine, capacity: u… Have a Question? Ask our expert

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- How is cold pressed peanut oil made?

- After the cold-pressed crude oil is filtered with frame filter, product oil is obtained, which will be packaged by a filling machine to form cold-pressed peanut oil products ( Fig. 3.8 ). Figure 3.8. Flow chart of equipment for cold pressing of peanut oil. 2.

- Voltage: 220V/380V