turnkey project sunflower oil expeller in estonia in botswana

- Usage: Sunflower Oil

- Production Capacity: 250-300KG/H

- Model Number: DYZ-300

- Voltage: 380V

- Power(W): 3KW

- Dimension(L*W*H): 2000x1200x2500mm

- Weight: 2200kg

- Certification: ISO CE SGS

- oil press machine japan: oil press machine japan

- Material: 316 Stainless Steel

- Barrel Dia: 40cm

- Cake oil rate: 3%

- Pressure: 35-50mpa

- Multi-purpose: yes

- Advantage: Energy Saving

- Color: Clients' requirements

- Raw material: Sunflower Seed

- Movable: Yes

Sunflower Oil Mill Plant. We are a well-known manufacturer of small, medium and large scale industrial sunflower seed oil mill plants. Our oil mill machinery and equipment deserve praise for their excellent quality. The sunflower seed producing countries are Ukraine, Russia, Argentina, China, Romania, Bulgaria, Turkey, Hungary, USA and Tanzania.

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

Oil Mill Machinery

- Usage: CBD Oil, Water Chilled

- Production Capacity: 1tpd

- Voltage: 380V/60Hz

- Dimension(L*W*H): 770*850*1320mm

- Weight: 157kg

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Sunflower Oil, CBD Oil, HEMP Oil

- Product name: CE industrial liquid circulating chillers system DLSB-50/40

- Application: Industrial Cooling Solutions

- Refrigerant: R404A

- Cooling capacity: 12775-650W

- Compressor power: 2.2~30kw

- Cooling type: Chilled Cooling Water

- Evaporator type: Stainless Steel Shell Tube

- Temperature range: -40C-RT

- Function: Controller

- After Warranty Service: Video technical support, Online support, Spare parts

- Certification: CE

Our oil mill machinery installation and turnkey solutions are designed to offer a seamless and hassle-free experience for our clients, covering every aspect of the project from conceptualization to full-scale operation. Our Oil Mill / Oil Plant turnkey projects are designed with a keen focus on cost-effectiveness.

Turnkey Solutions. Tinytech Udyog has been engaged in the business of cooking oil extraction machinery and edible oil refining since 1992. We undertake project execution on turnkey basis backed with team of highly qualified and experienced engineers. We provide superior quality of turnkey solutions and turnkey services.

Turnkey Soybean Oil Processing Project Installed In Africa

- Usage: Making Edible Oil

- Production Capacity: 5TPD-100TPD

- Voltage: 380V/50HZ/Triple phase

- Dimension(L*W*H): 2900*1850*3640mm

- Weight: 5500 kg

- Core Components: Motor, Engine

- Oil type: Sunflower Oil

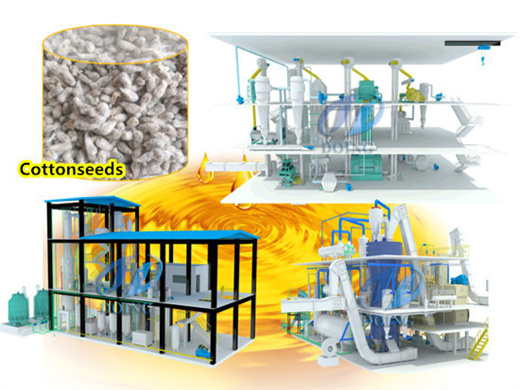

- Product name: cotton seed oil mill machinery

- Raw material: Sunflower ,Sunflower,Sunflower

- Section: pretreatment, extraction,refining

- Oil rate: meal residual: ≤ 1%, press cake residue ≤ 6%

- Capacity: 40-50Tons/24hrs

- Material: Carbon steel and stainless steel

- Price: bottom price, factory price

- Color: Clients' Requirements

- Name: Screw Oil Press Machine

- Function: Making Edible Oil

- After Warranty Service: Video technical support, Online support

- Certification: CE ISO

This is a turnkey soybean oil mill plant established in Africa for one of our customer, and this unit consists mainly of oil expeller, oil filtering equipment, cooking kettle, cleaning equipment, etc. It is a turnkey project with a raw material extraction capacity of 50 tonnes per day. If you are interested in starting your own soya bean oil.

In Dry milling Corn / Maize Flour is the main product. Oil content of Corn / Maize germ produced by Wet Milling is as high as 50% and that by Dry Milling is about 25%. We undertake turnkey project solutions for the complete Corn / Maize-Germ Oil Extraction Plant. Major Corn producing countries are USA, China, Brazil, Argentina, Mexico, Ukraine.

Crude Oil Processing -Oil Mill, Oil Expeller & Solvent

- After-sales Service: on Line Service

- Type: Oil Press

- Feature: Automation, Precision, High Efficiency

- Certification: ISO9001, CE

- Customized: Customized

- Transport Package: Wooden Case

- Production Capacity: 10, 000

Solvent extraction is a counter current extraction process for extracting crude edible oil from oilseeds and nuts using solvent, with Hexane. Hexane-based processes is popular for maximizing oil yield in excess of 95% with a solvent recovery of over 95% which in compare to 60 to 70% oil yield by mechanical expeller pressing. Thus Solvent.

This is a complete set of sunflower oil processing machine ordered by one of our client in Moldova, including equipment for seeds hulling, cooking, oil expelling, sieving, oil filtering, oil refining, bottling and labeling. It is turnkey project of 10TPD oil pressing and 3TPD refining. The refined sunflower seeds oil are bottled and labeled.

Sunflower Oil : Everything we need to know - Hongde Screw Press

- Usage: sasame

- Type: Smal scale Sunflower oil cold press

Automatic Grade: Semi-Automatic - Production Capacity: 35~550kg/h

- Voltage: adjustable

Power(W): 1.5KW - Dimension(L*W*H): 900*850*1550mm

- Weight: 1000kg

Certification: ISO9001 - Item: Smal scale Sunflower oil cold press

Mpa: 50 - Plant: 30~50 square meters

- Business type: Manufacturer

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA - Guarantee:

- Packing: Wooden package

Suitable objects: Sunflower etc. - Manufacturing experience: 30+ years

The sunflower oil is obtained through expeller pressing or solvent extraction methods, and than it is sent for oil filtration or oil refining and processed for various applications, including culinary use, skincare products, and industrial purposes such as biodiesel production. The resulting sunflower oil is a versatile and widely used product.

Oil Mill Projects. We has a qualified team who are technically experienced in giving special attention to the project evaluation process. We can provide professional guidance from the Blueprint for the Installation of the project. According to the local conditions, space requirement and environment restrictions, the customized turnkey solution.

- How to start a sunflower oil mill plant?

- Here we have listed some of the basic machinery required to Start a Sunflower Oil Mill Plant There are various processes involved in Sunflower Oil Mill Plants: Seed Cleaning, Seed Conditioning, Oil Extraction, Oil Filtration, Steam Generation and Oil Filling.

- Which countries produce sunflower seed oil?

- Our oil mill machinery and equipment deserve praise for their excellent quality. The sunflower seed producing countries are Ukraine, Russia, Argentina, China, Romania, Bulgaria, Turkey, Hungary, USA and Tanzania. We undertake turnkey project solutions for the complete Sesame Seed oil extraction plant.

- What are the processes involved in sunflower oil mill plants?

- There are various processes involved in Sunflower Oil Mill Plants: Seed Cleaning, Seed Conditioning, Oil Extraction, Oil Filtration, Steam Generation and Oil Filling. Prior to extraction, oilseed is passed through the seeds cleaner to remove the impurities such as dust, leaves and metals.

- How sunflower seeds are conditioned in a vertical cooking kettle?

- The Sunflower Seeds are conditioned using Steam in a Vertical Cooking Kettle. The conditioned sunflower seeds are fed into the chamber. A screw rotates inside the chamber which increases the pressure by reducing the length of the screw pitch in the direction of axial motion.