peanut oil cake solvent extraction machine in botswana

- Usage: Peanut Oil, Cooking Oil

- Production Capacity: 40-600kg/h

- Voltage: 220

- Dimension(L*W*H): 43*29*21cm

- Weight: 7.5 KG

- Warranty of core components: 2 years

- Core Components: Motor, PLC, Gear, Engine

- Oil type: Peanut Oil

- Product Name: Mini small cold press extractor machin automatic machine oil pressers

- Function: Oil Press + Drum Filter

- Material: Stainess Steel

- Keyword: oil pressers

- Feature: Automatic Machine

- Press type: Screw Cold Oil Press

- Power: 820W

- Application: Edible Oil Production

- Operation: Automatic Operate

- Motor: Pure Copper

Craft Flow for Peanut Oil Extraction Mill . Product advantages of peanut oil extraction. 1.Automatic temperature control: scientific heating, automatic temperature control press. 2.Auto oil filter:the use of the principle of negative pressure air,vacuum streaming technology, built-in vacuum shunt, oil, slag effective separation 3.Safe and convenient:the structure of the peanut oil extraction.

The solvent extraction method recovers almost all the oils and leaves behind only 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant etc. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%.

Groundnut Oil Making Process (Peanut), Business Plan

- Usage: Peanut Oil, Cooking Oil

- Type: Oil Filter

- Production Capacity: 120 to 180 L/H

- Voltage: 220v/380v 50hz

- Dimension(L*W*H): 1060*610*960

- Weight: 500 KG

- Core Components: Motor

- Oil type: Peanut Oil

- Application: Screw Oil Expeller

- Revolving speed: 1246

Groundnut or Peanut is the largest oilseed in India in terms of production. It accounted for about 35.99 percent of the oilseeds production of the country during 2007-08. Generally, 2.5 kg of groundnut to produce 1 liter of the groundnut oil. The cost of procurement and processing of the groundnut or peanut is around Rs. 90/kg.

As shown in Fig. 3.4, during the process the temperature rises from 60 to 90°C, the oil/residual oil ratio of the system decreases gradually, reaching 4.5% at 90°C. . However, during the process of the temperature rise, the content of the soluble protein of the residual cake decreases slightly at 60?70°C, and when the temperature exceeds 70°C, the content of the soluble protein of the.

Peanut meal | Feedipedia

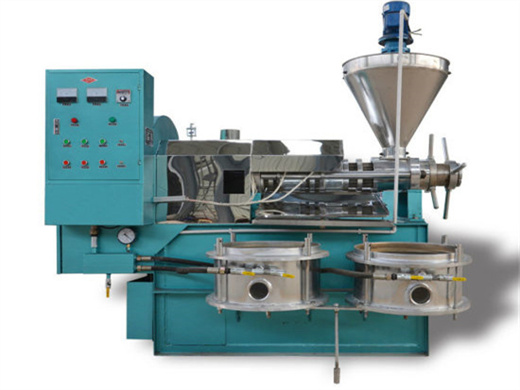

- Usage: hot/fry press, cold/raw press, about 150 types oil crops expellers

- Type: oil press machinery, oil expeller, screw oil press expeller

- Production Capacity: 1-100T/DAY

- Voltage: 220V/380V, 380V

- Dimension(L*W*H): 1400*1000*1500mm

- Weight: 440 KG

- Core Components: Motor, Peanut oil processing machine

- Oil type: Peanut Oil

- Main body motor power: 11~22KW

- Oil Filter power: 1.1~2.2KW

- Spiral Axes Rotation Speed: 90-150r/min

- Operation Quantity: 3.5-5.5t/24h

- Material: Stainess Steel

- Feature: Eco-Friendly

- Used for1: Peanut Peanut Peanut

- Certification: ISO9001

The skins are then removed and the kernels are ground into a paste, which is cooked and then pressed, yielding 25-40 kg of oil cake (Lambaré, 2015). Solvent extraction is less common than for other major oil meals. In the USA, as of 2014, only one processing plant (out of 4) was using solvent extraction . Solvent-extracted peanut meals have.

The peanut cake solvent extraction machine is part of peanut oil mill plant which is designed to extract oil from peanut cake.Our peanut cake solvent extraction machine adopt new type energy saving technolog, which can reduce steam, water and electric consumption. What's more, the peanut cake solvent extraction machine can ensure good quality.

Solvents for Oil Extraction from Peanut Press Cake

- Usage: Peanut Oil

- Type: Oil Pressing Machine, Peanut oil milling machine

Production Capacity: 1TPD-500TPD - Voltage: According to customer demand

Power(W): According to project - Dimension(L*W*H): According to project

- Weight: According to customer demand

Certification: ISO9001-2008, CE, BV - Color: According to customer demand

Production Material: Carbon steel, stainless steel - Raw material: Peanut

- Work principle: Mechanical principle

- Warranty period: One year

English manual: Yes - Factory visiting: Yes

the residual solid obtained from the extraction of peanut oil with a solvent, notably hexane, is used as animal feed to prepare soups and bakery products, such as cookies, as proposed by Tate et al. [24]. Based on the above information, it is necessary to compare hexane and ethanol for the extraction of residual oil from peanut press cake.

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

What are the common extraction methods of extracting peanut

- Usage: Nut Oil Press

- Type: Oil Pressing Machine

Production Capacity: 98%-100% - Voltage: 380

Power(W): 5.5KW~15KW - Dimension(L*W*H): 2200*1600*2150

- Weight: 780kg

Certification: CE ISO - Capacity of cold pressed Peanut oil: 35kg-400kg/h

Material of cold pressed Peanut oil: Stainless Steel SS304/316 - Residual oil rate: 5~7%

- Raw material: Peanut

- Warranty period: 12 months

- Application range: Oil Production Line

Feature of cold pressed Peanut oil: High Oil Yield Efficiency - Function of cold pressed Peanut oil: Produce High

- Character: Screw Oil Pressing Machines

The peanut oil pressing method belongs to purely physical squeezing oil producing technology, the whole pressing process does not add any additives, which ensures that the extracted peanut oil can be ate directly.To make the peanuts reach the best pressing state, we usually need to use a series of pretreatment machines, like: cleaning machine.

1. Solvent pumps: continuously spray solvent to the rotary-typr extractor. 2. Solvent extractor: spray and soak the soybean cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil). 3. DTDC: used to separate the solvent from the wet meal. 4. Miscella tank 1st.

- What is solvent extraction of peanut oil?

- The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

- What is the workflow of peanut oil solvent extraction plant?

- The workflow of peanut oil solvent extraction plant including extracting, desolventizing, evaporating and stripping, condensing and recovering. First, using organic solvents to extract oil from press peanut cake inside oil extractor, then we can get mixed oil and wet meal.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- How does peanut oil refining plant work?

- After being treated, the solvent in the mixed oil is evaporated and enters the solvent condensation recovery system.The peanut oil will be fed into the peanut oil refining plant. The solvent evaporated by the mixed oil evaporation system passes through the condenser, and then is stored for recycling in the next production.

- Voltage: 380

- Voltage: According to customer demand