first grade sunflower oil extraction plant in lesotho

- Type: Canola edible oil production machine

- Form: Oil

- Part: Seed

- Extraction Type: Solvent Extraction

- Packaging: Glass Container, Plastic Container

- Grade: best

- Model Number: Canola edible oil production machine

- Product Name: Canola edible oil production machine

- certification: BV&CE9001

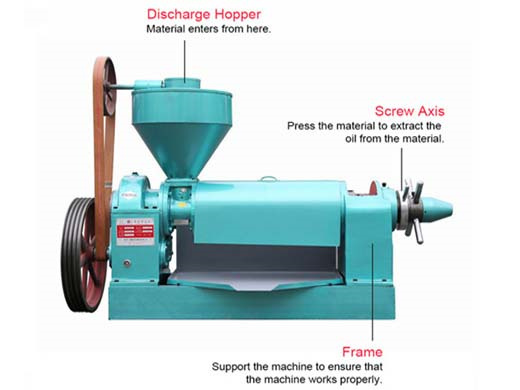

- funcation: oil press

- capacity: 10-1000TPD

- material: Sunflower, plam, cotton

- Weight: 1050 KG

- Warranty: 1 year

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

Sunflower Oil Extraction Process, Methods A Full Guide

- Usage: oil seed oil refining machine

- Type: oil seed oil refining machine

- Production Capacity: 1-100T/D

- Model Number: NP88

- Voltage: 380V/440v

- Power(W): 20-50KW

- Dimension(L*W*H): depond on capacity

- Weight: depond on capacity

- Certification: ISO9001/BV/CE

- Main export countries: Asia,Africa,Latin American,Malaysia...

- Packaging: Glass Container,Plastic Container

- Grade: first Grade

- refined oil: 1st grade edible oil

- oil content: 35%-48%

- fatty: 40~60.7

- protein: 20~37.2

- phosphlipid: 1.25~1.75

- saccharides: 5~15

- Refiney type: oil seed oil refining machine

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

Download scientific diagram | Extracting and refining steps of sunflower oil. from publication: Effects of refining process on sunflower oil minor components: A review | Sunflower oil is well.

Sunflower Oil Production Process Introduction - Edible Oil

- Usage: all nuts and seeds

- Model Number: PR70

- Power(W): 3kw

- Dimension(L*W*H): 1.3*0.78*1.4m

- Weight: 288

- Certification: CE Approved

- After-sales Service Provided: No overseas service provided

- Function: Automatic

- Capcity: 40-60kg/hour

- Color: Clients' Requirements

The processing characteristics of first-grade sunflower oil are: First of all, sunflower seeds are selected and cleaned to remove impurities, and then the seeds are de-husked and crushed. After that the embryo is flaked and steamed in the frying pan, the fried product is pre-squeezed out of the oil and the remaining oil is extracted by solvent.

Andreotti Impianti extraction plant is designed for oil solvent extraction starting from oil seeds flakes or pre-pressed cake. This environmental-friendly extraction system reduce the hexane content in the air emission, where the air is washed with mineral oil and the hexane is absorbed. Absorbed hexane is evaporated and recycled.

Cold pressed sunflower (Helianthus annuus L.) oil

- Usage: Sunflower oil

- Production Capacity: different capacity

- Voltage: 380V/Customize

- Dimension(L*W*H): according to specific capacity

- Weight: 4000 KG

- Core Components: Motor

- Oil type: Sunflower Oil

- Product name: oil refining equipment

- Keyword2: Sunflower oil extractions and refining machine

- Function: to refine various crude oil(crude Sunflower oil)

- Final finished product: refined oil, edible oil, RBD oil

- Raw material: different various vegetable crude oil

- Certification: CE ISO

- main process: degumming, decolizataion,bleaching, deodorization

- After-sales Service: Technology Supporting,engineer install&commissioning machine

- refining type: chemical and physical oil refinery

If, after (first) pressing, the seed of the cake contains significant amounts of “residual” oil, it can be pressed again: the second pressing (Fils, 2000).The utilization of pressing depends primarily on the type of raw material, that is, on the content of oil in the starting material for pressing, then on the preparation of the starting material, particle size composition, hull content.

exports sunflower oil to over than 100 countries of the world, which requires more efficient technologies for its production for the purpose of providing with world demand. For today, there are two methods of extracting oil plant raw materials: press and extraction. The advantage of the extraction method is the high degree of oil extraction of.

ABOUT - Ол?яр

- Usage: Sunflower Oil

- Type: Cold & Hot Pressing Machine, Sunflower preprocessing machines

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Model Number: pn013

- Voltage: 220V/380V

- Power(W): 7.5kw

- Dimension(L*W*H): 1910*550*765 mm

- Weight: 1200kg

- Certification: ISO9001

- Product name: Sunflower oil mill machines extractors press

sunflower oil of the “P” mark Shelf life: 24 months. The energy value of 100g of product 3696 kJ (899 kcal). Complies with all FSSC 22000. Majola Unrefined winterised first grade sunflower oil Shelf life: 15 months. The energy value of 100g of product 3694 kJ (899 kcal). Complies with all FSSC 22000. Oliyar MasterFry ?

The hot pressed oil sunflower can be pressed evenly when it reaches 70% or 80% roasting degree, with the highest oil yield and very fragrant oil. Step 2, Pressing. The round bar of the sunflower oil press in the sunflower oil production plant has a zigzag curve and a conical surface.

- What are the processes involved in sunflower oil mill plants?

- There are various processes involved in Sunflower Oil Mill Plants: Seed Cleaning, Seed Conditioning, Oil Extraction, Oil Filtration, Steam Generation and Oil Filling. Prior to extraction, oilseed is passed through the seeds cleaner to remove the impurities such as dust, leaves and metals.

- How to start a sunflower oil mill plant?

- Here we have listed some of the basic machinery required to Start a Sunflower Oil Mill Plant There are various processes involved in Sunflower Oil Mill Plants: Seed Cleaning, Seed Conditioning, Oil Extraction, Oil Filtration, Steam Generation and Oil Filling.

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- What is sunflower oil?

- Sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process.