high efficient oil seeds crushing sunflower press in malawi

- Usage: Sunflower Oil

- Production Capacity: 250-300KG/H

- Model Number: DYZ-300

- Voltage: 380V

- Power(W): 3KW

- Dimension(L*W*H): 2000x1200x2500mm

- Weight: 2200kg

- Certification: ISO CE SGS

- Sunflower oil press machine: Hydraulic Sunflower Seeds Oil Press Machine

- Material: 316 Stainless Steel

- Barrel Dia: 40cm

- Cake oil rate: 3%

- Pressure: 35-50mpa

- Multi-purpose: yes

- Advantage: Energy Saving

- Color: Clients' requirements

- Raw material: Sunflower Seed

- Movable: Yes

Dehulled se are sflaked from dehulled sunflower se with d atwin,crew pr iss to 0.35 mm to rupture cell structures and free the oil, highly efficient. steam-cooked and partially dried, then expressed at 80-105°C and 4-7% moisture until 15-18% oil remains. KEYWORDS: Dehulled sunflower seeds, oil expression, The twin,screw 3-4 mm thick presscake.

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Usage: Sunflower oil thresher

- Type: Sunflower oil thresher

Production Capacity: 10T-3000T/D - Voltage: 220V/380V/440V

Power(W): 10-50kw - Dimension(L*W*H): 1200*400*900mm3

- Weight: According to Sunflower oil processing capacity

Certification: ISO9001/CE/BV - Item: Sunflower oil thresher

, long term technical support - Supply scope: EPC/Turn-key Project

- Plam oil extraction method: Press method

Acid value: depend on the Sunflower fruits quality - Color of crude Sunflower oil: brown red

- Color of machine: depend on your requirement

Oil content in Sunflower fruit: 22% - Sunflower oil refining machine: available

- Raw material: Fresh Sunflower

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

The oil extraction by mechanical pressing is the most common method for continuous treatment of oleaginous seeds without solvent. Different types of presses can be used depending on the purpose (expeller, expander, and twin-screw extruder) and on the capacity range (3 kg h?1 to 150 t day?1). At the laboratory scale, many authors have highlighted the effect of operating parameters (screw.

A Twin-screw extruder for oil extraction: I. Direct

- Weight (KG): 600

- Core Components: Engine, Motor, Pressure vessel, Pump

- Product name: waste oil recycling filtration tank fuel decolourization machine

- Application: waste diesel oil filtering

- Material: Q235

- Filter media: silica gel or mineral sand

- Size: 0.8mm

- Usage: cleaning waste oil

- Brand: SIMBO

- Length: 1300mm

- color: blue /grey /white

- power: 7.5kw or 11kw

The positive impact of high temperatures has been observed in the pressing of sunflower seeds, where an oil extraction efficiency of 66% was obtained at 80°C, whereas 70% was obtained at 120°C.

Improved value chain coordination. The Malawi Oilseed Sector Transformation (MOST) programme aims to reduce poverty by facilitating changes in the cotton, groundnut, soybean and sunflower markets using a market systems approach. It aims to increase the incomes of at least 58,500 poor smallholder producers and entrepreneurs, at least 50 per cent.

A new twin screw press design for oil extraction of dehulled

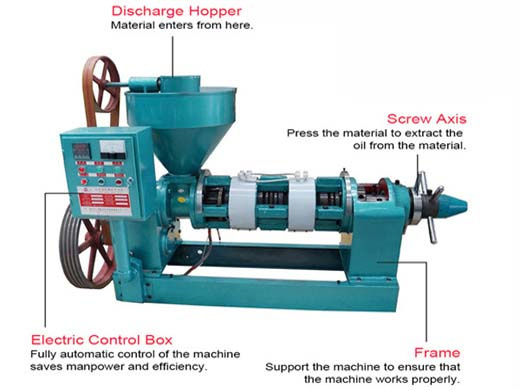

- Usage: Sunflower OIL, Cooking Oil extraction machine middle

- Type: Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1700*1300*1750mm

- Weight: 1200 KG, 30tons

- Warranty of core components: 2 years

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Sunflower Oil

- Product name: Sunflower oil extractor machinery

- Acid value: less than 1.0mg koh/g

- Material: steel,carbon steel

- residual oil in meal: less than 1%

- Dimension(L*W*H): : 1700*1300*1750mm

- Function: crude oil refinery to edible oil

- indine value: 44-46 gl/ 100g

The results were compared to a single-screw lab-scale press. Dehulled sunflower seed (wt, 6.0%; oil, 58.6%) without pretreatments (crushing or cooking) gave 93.6% oil recovery with the twin-screw press, in contrast to 20% oil recovery with the single-screw press. The oil expressed with a twin-screw press had less foreign material than the oil.

The ram press is a manually operated mechanical (Fig. 1) press capable of pressing a range of oil-seeds including sunflower, sesame and groundnuts, as well as seeds from pumpkin, rape, watermelon.

Research on mechanical?structure properties during sunflower

- Usage: Sunflower ,cocoa oil press

- Production Capacity: 10TPD-100%

- Voltage: 220V/380V

- Dimension(L*W*H): 800*950*1050mm

- Weight: 550 KG

- Core Components: Motor

- Oil type: Sunflower Oil

- Product name: hydraulic oil press machine price

- Raw material: Sunflower , cocoa

- Advantage: Energy Saving, High Oil Yield, Simple Operation, High Efficient

- Capacity: 120kg/h

- Material: 304 Stainless Steel or Carbon Steel

- Item: Edible Oil Press

- Oil Yield: 40-70%

- Name: Oil Pressing Machine

- Function: Press Oil Seeds

- Application: Edible Oil Production

The traditional sunflower seed oil extraction method is press ex - traction, which can retain good oil quality and unique flavor (Kartika et al., 2005). It is of great significance to study the mechanical prop-erties of sunflower seeds for oil extraction. So far, many scholars at home and abroad have conducted much research on the mechanical

Introduction. Sunflower (Helianthus annuus L.) is cultivated for its seeds’ high oil content.Oil represents up to 80% of its economic value. The industrial processes for oil production consist of four successive stages: trituration, pressing, extraction of the residual oil using hexane and refining (Isobe et al., 1992, Rosenthal et al., 1996).

- Voltage: 220V/380V/440V