low residual oil in cake sunflower oil press in cape town

- Usage: for cooking oil

- Type:

- Production Capacity: 200~2000T/D(daily processing capacity)

- Model Number: POM

- Voltage: 380

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Certification: ISO9001

- Materials:

- Brands:

- After-sale services:

- Expanding,Extraction,Refinery:

carried out using such a con?guration, the corresponding cake meal contained less than 10% residual oil, and the total oil yield was 78% in the best operating conditions. Neverthe less, the contribution of the aqueous extraction stage was extremely limited, less than 5% in the best trial, partly due to a ratio of the water to the press cake.

According to [34], sunflower press cake has a residual oil content of up to 18%, which due to it being a semi-drying oil, slowly hardens during thermal treatment at 110 C, thus forming a.

Aqueous extraction of residual oil from sunflower press cake

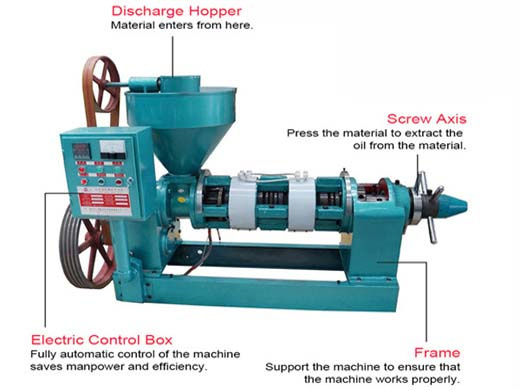

- Usage: Sunflower Oil

- Type: For Sunflower oil production machine prices usage

- Production Capacity: 50-3000TPD

- Model Number: JXSE 1231

- Voltage: 380v 440v

- Power(W): As Sunflower oil production machine prices output every day

- Dimension(L*W*H): As your Sunflower oil production machine prices ouput per day

- Weight: Depend on Sunflower oil production machine prices output

- Certification: ISO9001

- Item: Sunflower oil production machine prices

- Material: stainless steel

- Application: for all seeds extraction

- Output: as Sunflower oil production machine prices request

- Residual oil in meal: less than 1%

- Solvent consumption: less than 2kg/t

- Power consumption: not more than 15KWh/T

- Process of refining: Degumming ,Decolorization

- Rate of Sunflower extraction: 38%- 42 %

- Payment: l/c t/t

The corresponding oil yields were 19% and 41%, respectively, with higher ratios of the water to the residual oil (36:1 in the case of press cake A, 40:1 in the case of press cake B). When the inlet flow rate of the whole sunflower seeds was too low ( Table 6 ; trial 9), even if the aqueous extraction stage was more efficient, the total oil.

DOI: 10.1016/J.INDCROP.2008.09.001 Corpus ID: 51753365; Aqueous extraction of residual oil from sunflower press cake using a twin-screw extruder: Feasibility study @article{Evon2009AqueousEO, title={Aqueous extraction of residual oil from sunflower press cake using a twin-screw extruder: Feasibility study}, author={Philippe Evon and Virginie Vandenbossche and Pierre-Yves Pontalier and Luc.

Aqueous extraction of residual oil from sunflower press cake

- Usage: Sunflower OIL, Cooking Oil

- Production Capacity: 180-260kg/h

- Voltage: 220V/380V

- Dimension(L*W*H): 2130x1050x2850mm

- Weight: 1480 KG

- Core Components: Motor, Pump, Bearing, Other

- Oil type: Sunflower Oil

- material: Stainless steel

- Application: Oil Production Line

- Advantage: Long Service Life

- Capacity: 180-260kg/h

- MOQ: 1 Set

- Color: Customers' Requirements

- Quality: High Level

Pressing was therefore much more efficient even if no filtrate (filtrate 1′) was collected in module 6. The moisture content of press cakes A and B were 8% and 1% (Table 2), respectively. It confirmed the better. Conclusion. The aqueous extraction of the residual oil from sunflower press cakes was carried out using the twin-screw extrusion.

DSC analysis of sunflower press cakes SME2 = ′ +Q , QC1 LCR Differential Scanning Calorimetry (DSC) analysis was used to where SME2 is the specific mechanical energy consumed by evaluate the denaturation level of proteins in sunflower press the motor per unit weight of solid matters (press cake and cakes (Rouilly et al., 2003).

Extraction of proteins and residual oil from flax (Linum

- Usage: All kinds of oil seed

- Production Capacity: 200-300KG / H

- Model Number: 6YL series screw oil press

- Voltage: 220V, 380V, or other, 220v/other

- Power(W): 11000

- Dimension(L*W*H): 900*750*1400

- Weight: 880kg

- Certification: CE& BV

- Product type: hydraulic Sunflower Oil press machine

- Raw material: Sunflower Seed

- Application: oil press

- Warranty: One Year

- Feature: High Output

- Advantage: dual pressure

- Material: Carbon Steel Stainless Steel

- Character: cold and hot press

- Price: Negotiable

The oilseed pressing process for the production of vegetable oils creates large amounts of cakes as by-products that contain high-added-value substances such as proteins and lipids. This work targets the chemical characterization of flax cake (FC), camelina cake (CC), and sunflower cake (SC) in order to evaluate the composition of proteins and residual oil, which are two of the main components.

esting components of the cakes are residual oils, mostly tri-glycerides, accounting usually for 8?10%, and different amounts of cellulose, lignin, and other compounds [7]. Therefore, the large availability and low cost make press cakes attractive raw materials, especially to obtain and valo-rize proteins and residual oils for various.

Sunflower oil cake (OK-Net Ecofeed Practice Abstract)

- Usage: Sunflower Oil

- Production Capacity: 150-300kg/h

- Voltage: 220v/380v/Customer request

- Dimension(L*W*H): 1900*1400*1700mm

- Weight: 1100 KG

- Core Components: Motor

- Oil type: Sunflower Oil

- Name: Sunflower oil press machine

- Raw material: Sunflower Sunflower

- Function: Oil Pressing

- Operation: Automatic Operate

- Advantage: Energy Saving Low Residual

- Oil rate: Meal Residual: 1%

- Capacity: Large

- Material: Stainess Steel

- Processing Types: Screw Pressing

- Keep working: 24 Hours

Sunflower oil cake is a high protein and fat feed source for livestock. It is a by-product obtained from the extraction of oil from sunflower seeds. It can be obtained by mechanical pressing resulting in a ?cake“ (see Figure 1) containing 15-20 % oil or by solvent, which increases the quantity of oil. In organic farming, oil may only be.

Highest oil extraction yield (70.6%) with good press cake quality (residual oil content lower than 8%) was obtained under operating conditions of 153 rpm screw rotation speed, 5.16 kg/h inlet flow.