save labour sunflower oil dewaxing machine in congo

- Usage: Sunflower Oil, Sunflower EDIBLE OIL

- Production Capacity: 1-3t

- Voltage: 220V/330V

- Dimension(L*W*H): depends on capacity

- Weight: 5000 KG

- Warranty: 1 Year, One Year's Guarantee

- Warranty of core components: Not Available

- Core Components: PLC

- Oil type: Sunflower Oil

- Raw material: Sunflower

- Name: Edible Sunflower Oil Refining Machine

- Capacity: 1 to 20t/d

- Material: 304 Stainless Steel

- Feature: Turnkey Solution

- Item: FOB

- Processing: Semi continious

- Quality: Top Level

- After-sales Service: Life long service

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Certification: CE

Dry dewaxing also has its limitations, such as a maximum wax content of 900 ppm for the feedstock to pass the 24-hour cold test. To achieve effective wax removal, many edible oil producers now combine wet dewaxing and dry dewaxing processes in their refining plants. This combination enables oil producers to pass the 72-hour cold test.

When oils like SFO, RBO, & Corn oil are subjected to dewaxing, mainly the wax that is aimed for separation. Thus in simple words, cooling oil to remove high-melting components is known as winterizing.

Why does sunflower oil need dewaxing?_Tech

- Usage: Cooking Oil

- Production Capacity: 15-20kg/h

- Voltage: 220V

- Dimension(L*W*H): 640*290*680mm

- Weight: 73 KG

- Warranty of core components: 6 Months

- Core Components: Other

- Oil type: Sunflower Oil

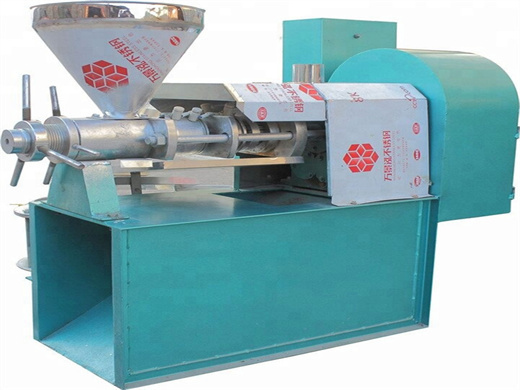

- Product name: Mini Oil Press Machine for small business

- Application: Edible Oil Production

- Function: Press Oil Seeds and vegetable

- Feature: Cold Pressing

- Capacity: 15~20kg/h

- Advantage: Simple Operation

- Application range: Edible oil production

- Material: 304 Stainless Steel

- Machinery type: Automatic Oil Mill Machine

- Package: Wooden Case

4. At last, sunflower oil is pumped into filter machine to separate the wax and sunflower oil. The above is the introduction of sunflower oil dewaxing process. If sunflower oil is not dewaxed, the presence of wax makes the oil appear cloudy at room temperature. But after dewaxing, the sunflower oil remains clear after 24h of storage at 0?C.

The isoparaffins structures formation improves the dewaxing yield at 90.7% reported on the miscella crude oil with 270 ppm waxes content with an almost double-cold dewaxed oil stability.

Dewaxing Process, Oil Dewaxing Process, Sunflower Oil

- Usage: Sunflower Oil, Sunflower EDIBLE OIL

- Type: Vegetable Oil Processing Equipment

- Production Capacity: 5TPD

- Voltage: 220V/380V

- Dimension(L*W*H): 670*950*1460mm

- Weight: 924kg

- Core Components: Motor, PLC, Hydraulic system

- Raw material: Sunflower , Sunflower , Sunflower etc.

- Capacity: 34-51 kg/h

- Material: Alloy

- Item: FOB

- Application: Edible Oil Production

- Processing Types: Hydraulic Press

- Process: Batch-type

- MOQ: 1 Set

- Operation: Easily

- Shipping: Sea

- After Warranty Service: Video technical support, Online support, Spare parts

- Local Service Location: India, Colombia

- Certification: CE ISO

The reason for hazy appearance is due to the precipitation of dissolved waxes. The presence of wax makes the oil appear cloudy at room temperature. The oil normally becomes cloudy in 5?6 h but with proper dewaxing the oil remains clear after 24h of storage at 0?C. Dewaxing is carried out by chilling the oil up to 10-15°C into the crystallizers.

The low solubility of wax in oil at low temperatures, where the oil remains liquid, forms the basis of common dewaxing processes. They cause the wax to crystallize by cooling the oil, and then they remove the crystals. There is a problem, though. The oil viscosity increases considerably when the oil is cooled down.

Dewaxing - Farmet

- Usage: black Sunflower hull extract

- Type: Vegetable Seed Oil Machine

- Production Capacity: 100%

- Model Number: DT-150

- Voltage: 220V/380V

- Power(W): 22kw/h

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 40tons

- Certification: ISO CE

- Capacity: 10-500tpd

- Application: Sunflower

- Oil rate: 18-22%

- Processing capacity: 20tpd to 200tpd

- Steam consumption: ≤280Kg/T (0.8MPa)

- Power consumption: ≤ 15KWh/T

- Solvent consumption: ≤3Kg/T(6#solvent oil)

- Residual oil in meal: ≤1%

- Residual solvent in finished meal: ≤ 300PPM (qualified detonated experiment )

The highest wax content (up to 1,000 ppm) is found in oil pressed out of unhulled sunflower seeds. Pressing hulled seeds usually results in an oil with less than 200 ppm of wax. The dewaxing technology can be supplied at capacities between 1 and 10 tons of oil per hour; wax content at output tends to be less than 20 ppm.

Dewaxing or Winterization is a process to remove solids (saturated glycerides or waxes) from oil. These solids cause cloudiness in oil at low temperature. This process is suitable for oils like Sunflower Oil, Cottonseed Oil, Corn Oil, Ricebran Oil etc which have wax contents more than permissible limit. The oil is mixed with filter-aid and is.

A Modern Dewaxing Technology For Edible Oils Refining

- Usage: Sunflower Oil ,Sunflower Oil ,

- Type: Oil Extraction Machine

- Production Capacity: 1t/day-1t/hour-100%

- Voltage: 220V/380V

- Dimension(L*W*H): 1050*800*1400mm

- Weight: 330 KG

- Core Components: Motor, Bearing

- Oil type: CUSTOM

- Name: high efficiency Sunflower oil press machine with filter shanghai

- Capacity: 200-250Kg/Hour

- Material: stainless steel and carbon steel

- Usage range: Sunflower Oil ,Sunflower Oil ,

- Oil-content rate: less than 8%

- Wearing parts: Loops\spirals\bars

- HS CODE: 8479200000

- Certification: ISO CE

The dewaxing process was analysed in case of high-oleic sunflower crude oil samples with 75% oleic acid content and up to 5% saturated acids in the triacylglycerols native structures.

How the dewaxing process works Wet dewaxing & Dry dewaxing. In most of the cases, it is important to note that wet dewaxing alone removes sufficient amounts of wax to achieve the oil stability required to pass the 24-hour cold test; this is based on average quality sunflower oil with the wax content 600 ppm.

- Is dewaxing required for edible oil refining?

- Dewaxing may be the fifth process considered for the edible oil refining. It is not a compulsory process and it is not required for every type of oil. Dewaxing is performed only for high wax containing oils such as Sunflower Oil, Rice Bran Oil, Corn Oil etc.

- What is a tinytech dewaxing plant?

- Dewaxing is performed only for high wax containing oils such as Sunflower Oil, Rice Bran Oil, Corn Oil etc. Tinytech Dewaxing Plants are incorporated with intrinsically designed Crystallizer Equipments which are specially made of very slow cooling with continuous agitation for better heat transfer.

- Why is dewaxing important?

- Dewaxing is critical to enhancing edible oil stability as well as preventing crystal formation and cloudiness at low temperatures. Getting the most out of crude sunflower, corn and cottonseed oils requires the right system optimized to your process requirements.

- How much does Naomi kamuwikeni sell a bag of sunflower?

- Mrs Kamuwikeni can sell a 25-kg bag of sunflower for 150 Zambia Kwacha ($6.60 US). Or she can process that bag into 10 litres of cooking oil and sell it for 430 Kwacha ($19 US). It’s seven o’clock in the morning and Naomi Kamuwikeni is quickly walking to the oil expeller at Gondar market. She is carrying sunflowers to process into oil.