small sunflower seeds oil extraction oil plant in sri lanka

- Usage: all kinds of seeds

- Production Capacity: 40-650kg/h

- Voltage: 380v,220v

- Dimension(L*W*H): 1080x920x1830mm

- Weight: 460kg

- Core Components: Gear, Gearbox

- Color: Different according to requirement

- Control box: Yes

- English manual: Yes

- Feature: With the auto frying

- Raw material: Oil Seeds

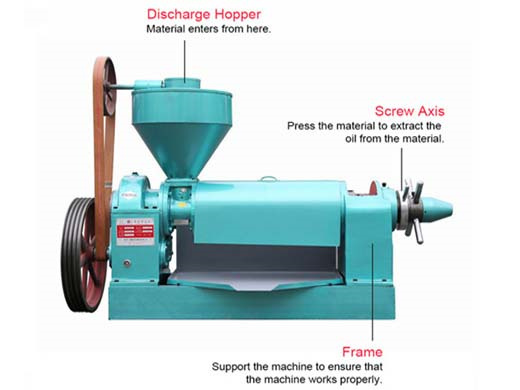

- Name: oil expeller

- Function: Making Edible Oil

- Product name: Edible Oil

- Application: Screw Oil Expeller

- Advantage: Energy Saving

- After Warranty Service: Video technical support, Online support, Spare parts

- Certification: CE,ISO

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Prepress solvent extraction relies on exerting medium pressure on the prepared seed to separate the majority of the oil, followed by solvent extraction to separate additional oil from the solids fraction, recovering over 40% oil from the seed in modern crushing plants. In a typical sunflower crushing plant using the prepress solvent extraction.

Field Crops Sunflower Department of Agriculture Sri lanka

- Usage: Sunflower Sunflower

- Production Capacity: 20tpd-100%

- Model Number: 6YL-80

- Voltage: 220V/380V

- Power: 5.5kw

- Dimension(L*W*H): 1320*540*1020mm

- Weight: 1200kg

- Application: Edible grain and oil production line

Seed production is comparatively easy. The oil yield is comparatively low (25-35%). The empty seed percentage can be high, if artificial pollination is not practiced. Hybrids. Seed yield and oil yield is higher (45-50%) than open pollinated varieties. Most of the imported types are now hybrids. Therefore, seed production cannot be done locally.

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

The sunflower seeds oil extraction: the mechanism and

- Usage: Sunflower oil

- Type: Oil Extraction Machine

- Production Capacity: >4.5TPD

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1720*580*1185

- Weight: 600 KG

- Core Components: Gear, Bearing, Gearbox

- Oil type: Sunflower Oil

- Color: Customized

- Advantage: High Oil output

- Capacity: 4.5Ton/Day

- Oil content dry cake: <7.8%

- Noise: <80dB

- Product name: Sunflower oil mill

- Application: Sunflower

- Function: Making Sunflower oil

- Name: Sunflower oil mill

extraction of oil from amaranth seeds and rapeseed under the conditions of a moving layer,” Scientific works of the Odessa National Academy of Food Technologies , vol. 41, no. 1, pp. 128-133, 2012.

exports sunflower oil to over than 100 countries of the world, which requires more efficient technologies for its production for the purpose of providing with world demand. For today, there are two methods of extracting oil plant raw materials: press and extraction. The advantage of the extraction method is the high degree of oil extraction of.

Supercritical extraction of sunflower seed oil: Experimental

- Usage: screw Sunflower oil press machine

- Type: screw Sunflower oil press machine

Production Capacity: 400~600kg/h - Voltage: 220V/380V

Power(W): 18.5kw - Dimension(L*W*H): 1500*1600*2500mm

- Weight: 2000kg

Certification: ISO9001 - Keywords: screw Sunflower oil press machine

Raw material: Sunflower Seed - Advantage: Energy Saving

- Machine Material: Part of are stainless steel

Warranty: 1year - Residual: Less than5%

- Supplier strength: with 30 years experiences

Machine color: According customer needs - Product name: screw Sunflower oil press machine

- Business type: manufactory

Stahl et al. [3] measured the solubility of sunflower seed oil in CO 2 at various pressure values (in the range between 150 and 700 bar) and at a temperature of 40 °C; the authors [3] performed extractions with hexane at atmospheric pressure and with CO 2 in the pressure range between 250 and 350 bar, obtaining an oil yield (kg oil /kg seeds.

The application of pulsed electric field (PEF) as one of the nonthermal intensification methods has been proposed to increase oil yield extraction from sunflower seeds. PEF treatments have been carried out under various electrical parameters such as electric field, pulsed frequency, pulse width, time of treatment and sample conductivity. 55 fractional factorial design has been used for the.

Research on mechanical?structure properties during sunflower

- Usage: Cooking Oil

- Type: Oil Extraction Machine

- Production Capacity: 10TPD

- Voltage: 220V380V

- Dimension(L*W*H): 1.2*0.78*1.1m

- Weight: 300 KG

- Core Components: Motor, Pressure vessel, PLC

- Oil type: Sunflower Oil

- Product name: cooking oil Sunflower oil production line

- Method to press: Screw Squeezed Press

- type: Oil Pressers

- Raw material: Sunflower Seed, Sunflower , sunflower,etc

- Keyword: oil press machine

- Application range: Crude Seed Oil

- Function: Oil Mill Making Pressing Extracting Machine

- Used For: Sunflower /Sunflower seeds

- Processing Types: Oil Press

- Extraction of Oilseeds: : 90% Oil Yield

The traditional sunflower seed oil extraction method is press ex - traction, which can retain good oil quality and unique flavor (Kartika et al., 2005). It is of great significance to study the mechanical prop-erties of sunflower seeds for oil extraction. So far, many scholars at home and abroad have conducted much research on the mechanical

The oil yield was found to increase by 9.1% after treatment of sunflower seeds by variation of PEF parameters: 30 s under an electric field of 7.0 kV/cm having frequency of 15 Hz, solvent content of 40 wt% and pulse width of 30 μs.

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- What is sunflower seed processing?

- Sunflower seed processing focuses on sunflower oil as the most valuable product. It is used as high-value oil in various food applications. The deoiled meal is considered a byproduct and is mostly used as animal feed. In 2011, annual world production of deoiled sunflower meal was at 16 million tons ( FAO, 2013 ).

- Does Ukraine export sunflower oil?

- It should be emphasized that Ukraine exports sunflower oil to over than 100 countries of the world, which requires more efficient technologies for its production for the purpose of providing with world demand. For today, there are two methods of extracting oil plant raw materials: press and extraction.

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- Voltage: 220V/380V