made sunflower oil extraction plant cost in togo

- Usage: Sunflower Oil, home ues

- Type: Seed Roaster

- Production Capacity: 300-400kg/h

- Voltage: 220V

- Dimension(L*W*H): 2.1*1.5*1.8m

- Weight: 1000kg

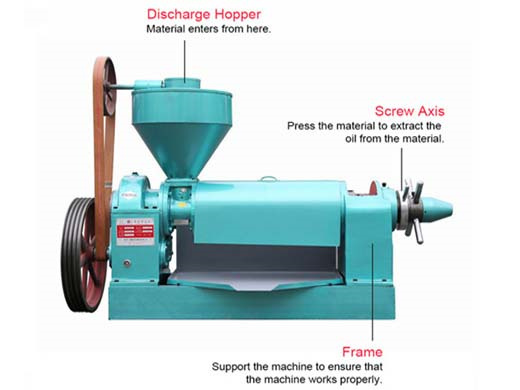

- Core Components: Propeller, screw

- Name: Screw type Sunflower kernel oil press machine with best price

- Squeezer diameter: 125mm

- Squeezer speed: 37r/m

- Main motor power: 15kw

- Capacity(cold press): 300-400kg/h

- Operation: easy to operate

- Material: stainless steel

- Color: as per your requirement

- After-sale service: send technician

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Certification: ISO9001

Estimated Cost per Ton ($) Peanut Oil. $800. Palm Oil. $900. Sunflower Seed Oil. $700. Please note that these amounts are for illustrative purposes only and may not reflect the actual current market prices. It's essential to consult the latest data and conduct a thorough cost analysis for accurate estimations.

The oil type sunflower seeds, which are used for extraction of oil, contain about 38 to 50% oil and about 20% protein. In other terms, 1.398 kg of sunflower seeds can produce one litre (1 lit) of oil. The actual oil yield depends on the geographical factors (soil, weather), quality of seeds, extraction methods and parameters, etc.

Sunflower Oil Extraction Process, Methods A Full Guide

- Usage: Sunflower Oil

- Production Capacity: 5-500 TPD

- Model Number: X1598

- Voltage: 440V

- Weight: 500TONS

- Certification: ISO,CE

- After-sales Service Provided: Engineers available to service machinery overseas

Cost of Sunflower oil extraction machine: Cost of automatic Sunflower oil extraction machine approximately, Rs 1.45 Lakh/Piece. Benefits of Sunflower oil. May enhance oral health. Sunflower oil is extremely useful for oil pulling. Sunflower oil reduces plaque-related gingivitis.

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

A Step-by-Step Guide on How Sunflower Oil is Made

- Usage: seeds oil, edible oil solvent extraction machine

- Production Capacity: Sunflower seeds oil extraction machine

- Model Number: Sunflower seeds oil extraction machine

- Voltage: 220V&380V

- Power(W): according to the capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Certification: CE&BV9001

- solvent:

- residual oil in cake: 1%

- extractor type: rotocel extractor

- capacity: 30-300TPD oil solvent extraction equipment

- Equipment material: Stainless steel or carbon steel

- Raw material: Sunflower Seed

- Extractor system: Toasting system

- Use:

- Solvent:

Oil refining is a multi-stage process, with the steps involved varying greatly based on the oil in question. When it comes to sunflower oil, the steps that are critical in the production of clear, high quality, and safe edible oil are degumming, alkali neutralisation, bleaching, dewaxing, deodorisation, and an optional winterization process.

Launch of the extraction shop, start of sunflower seeds processing (December 17, 1947). 1949 - commissioning of the soap-making area. 1948, (March) start of the margarine plant construction. 1951, (December) - the first output of margarine products. 1955 - merger of the fat plant and oil and fat plant into one enterprise.

How much does it cost to build a sunflower oil processing plant?

- Usage: Sunflower Oil

- Type: Cooking Oil Processing Machine, Crude Oil Refinery Oil Degumming, Dephosphorization, Decolorization

- Production Capacity: 10-500ton/day

- Voltage: 380v

- Dimension(L*W*H): 1500X580X1350mm

- Weight: 140 KG

- Warranty: 1 Year, 1year

- Core Components: Other, Gear

- Oil type: Sunflower Oil

- Name: Oil Refinery Sunflower Oil Degumming, Dephosphorization, Decolorization

- MOQ: 1 Set

- Raw material: Oil Seeds

- Advantage: Simple Operation

- oil type: Crude Oil Refinery Oil Degumming, Dephosphorization, Decolorization

- Item: Crude Oil Refinery Oil Degumming, Dephosphorization, Decolorization

- After-sales Service: Technology Supporting

- Delivery: 15 Working Days

Because the cost of building a sunflower oil processing plant is affected by many factors, such as: factory cost, raw materials cost, equipment cost, shipment cost, workers cost, operating running cost and so on. Next, Doing Holdings - Henan Glory Company will analyze the costs of building a sunflower oil processing plant for you. Sunflower oil.

Andreotti Impianti extraction plant is designed for oil solvent extraction starting from oil seeds flakes or pre-pressed cake. This environmental-friendly extraction system reduce the hexane content in the air emission, where the air is washed with mineral oil and the hexane is absorbed. Absorbed hexane is evaporated and recycled.

Establish A Small Scale Sunflower Oil Production Line

- Usage: edible oil extraction

- Type: Cooking Oil Press Machine

- Production Capacity: 40-500 kg/h

- Voltage: 380V/50HZ

- Dimension(L*W*H): 880x440x770mm

- Weight: 160kg

- Core Components: Motor

- Product name: 6YL-68 Oil Press Machine

- Oil rate and lever: oil yield≥98%, cake≤5% , meal residual≤1% , lever 1,1st grade oil

- Material: carbon steel or stainless steel

- Key words: Sunflower Oil Extraction Machine

- Raw material: Sunflower,Sunflower,

- Quality: china best brand and quality

- After-sales service: provide longlife technical support

- Warranty period: 1 years

- Application: Agriculture Vegetable Seeds

- Color: According to your request

- After Warranty Service: Video technical support, Online support

- Certification: CE, ISO, BV

Here we can give your some references on equipment cost of sunflower cooking oil production line: The cost of 5ton/day oil pressing line is about $5500. The cost of 1ton/day oil refinery plant is about $19800. For 1ton/day sunflower oil dewaxing machine, the price is about $13000.

Step 1: First, the extractor will allow the solvent to come in contact with the plant or seeds, completely saturating them. Step 2: After that, the compounds of the seeds will begin to separate. How long this takes depends on the process the extractor chooses to perform. Step 3: Next, the extractor will draw out the desirable compounds.