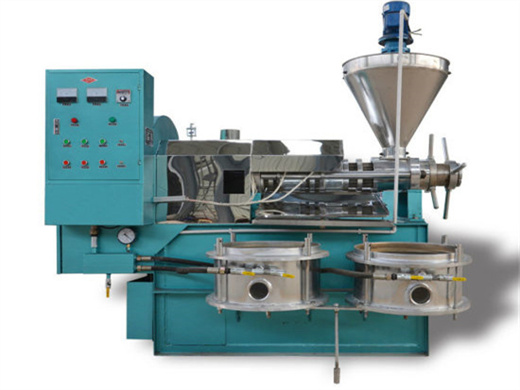

peanut oil extraction machine briquette machine in indonesia

- Usage: pre-press high oil content oilseeds

- Type: Cold & Hot Pressing Machine

Production Capacity: 200~300kg/h - Voltage: 220V~380V, adjustable

Power(W): 110kw - Dimension(L*W*H): 4832*2917*3236mm

- Weight: 12650kg

Certification: ISO9001 - Warranty: 1 Year

Business type: manufacturer - Net weight: 12650kg

- Property: steady and eco-friendly

Capacity: 20~50T/D - Residual oil in cake: 15~18%

- Cultivation Type: organic

Power: 110kw A Comprehensive Order of Briquette Charcoal Plant. To kick-start this endeavor, the Indonesian factory placed a substantial order with Shuliy Machinery, totaling over $60,000. The order comprised a complete set of charcoal briquette processing equipment to ensure a seamless production process. briquette charcoal processing plant.

It can be judged by the color of peanuts. 3. Feeding and pressing. Put the fried peanuts into the oil press while hot. If equipped with a feeding machine, automatic feeding is realized. 4. Filter machine. The crude oil squeezed out by the peanut oil press needs to be filtered by a filter, which can remove impurities in the crude oil.

Design and analysis of briquette molding machine

- Voltage: 220V

- Dimension(L*W*H): 38*38*38cm

- Weight: 12 KG

- Core Components: Motor, Other

- Oil type: Plant Oil

- Usage: Essential Oil Extracting Machine Distiller

- Product name: Essential Oil Making Machine

- Function: Essential Oil Extraction

- Raw material: Rose

- Application: Plant

- Capacity: 2800ml/h

- Feature: Multifunction High Efficient

Things to be considered first in the machine's design are the specifications of pressure and material used. The briquette machine frame design is shown in Figure 2. The material specification used for the molding machine is shown in Table 1. This briquette machine frame has 500 mm x 400 mm x 1,100 mm in size. Fig. 2.

Walnut shells can be used as fuels in power plants directly or as biochars obtained by pyrolysis or torrefaction. They are an example of clean waste biomass which shows a low ash content and a high Net Calorific Value, making them excellent for energy recovery in industrial and non-industrial applications, such as in bakeries, restaurants, and homes. Their main inconvenience is their low bulk.

Guide to Briquetting Presses: Types, Processes, and Uses

- Usage: Peanut Oil, Cooking Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 300-500kg/h

- Voltage: 220V/380V/CUSTOMIZED

- Dimension(L*W*H): 2450*790*2050mm

- Weight: 1020 KG

- Warranty: 5 years

- Core Components: Motor, Gear, Bearing

- Oil type: Peanut Oil

- Raw material: Peanut

- Product name: Oli Press Machine

- Name: Automatic Oil Press Machine

- Color: Custom-made

- Application range: Oil Seed press Machine

- Character: Oil Processing Line

- Function: Oil Pressing

Here is a list of the types of briquetting presses that can be used for manufacturing biomass briquettes. Piston Press. Hydraulic Press. Manual Press. Screw press. Roller Press. 1. Piston Press. This mechanical briquetting press is made up of a ram (piston) and a die.

From scrap to purpose, harness the power of briquetting to create value from your waste. Benefits of briquette machines include: Volume of input material can be reduced by up to 90%. Improved waste-material handling. Minimised disposal costs. Gaining of storage space.

Charcoal briquettes production line - Shuliy Machinery

- Usage: extraction

- Type: Oil Extraction Machine

- Production Capacity: 75-1250kg/h

- Voltage: 110V / 220V

- Dimension(L*W*H): 660*300*450mm

- Weight: 24.5 KG

- Core Components: Motor

- Oil type: Peanut Oil,attrValueId: 13238208

Among them, the briquettes extruder machine is the main equipment of the charcoal briquettes production line, which mainly processes the charcoal powder into various shapes and sizes. Common briquettes are square and hexagonal in shape. By changing with different extruding molds, we can customize the briquettes’ shapes.

Cold Pressing Peanut Oil: Integrated Screw Oil Press Advantages. 1. A wide range of application. It can press more than 20 kinds of oil plant seeds, such as soybean, peanut, sesame, rapeseed, sunflower, olive, palm, peanut and flax seed, etc. 2. High oil yield and purer oil. The equipped vacuum filter is used to remove residue to ensure the.

Peanut Oil Extraction Methods

- Usage: Peanut Oil, All kinds of oil seeds

- Type: Cold Pressing Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 380V/50HZ

- Dimension(L*W*H): L*W*H: 1900*1500*1800mm

- Weight: 1100 KG

- Warranty: 1 Year, 12 Months

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Peanut/Mustard Seeds Oil Extraction

- Oil type: Peanut Oil

- Name: Peanut/Mustard Seeds Oil Extraction

- Application: Oil Production Line

- Capacity: 30t/d

- Used for: Pressed Vegetable Oil

- Material: Stainess Steel

- Quality: ISO Certification

- Extraction of Oilseeds: 98% Oil Yield

- Processing Types: Seed Oil Press Machine Extracor

- Feature: Energy Consumption

The way of steaming, the effect is very good. In addition, when the press is pressed, the setting of the temperature of the oil press is also very important. If it is to make the oil taste strong, the temperature can be a little higher. If it is for the sake of good oil quality, it is recommended that the temperature be set at about 140 degrees.

Production steps of peanut oil extraction. Peanut Shelling Machine. 1, Oil extraction of peanuts first to go through the shell, select the sprouted and bad, before pressing peanuts can manually peel off peanut shells, but this is more time-consuming, generally only when the amount of family oil extraction is small, only in advance of shelling.

- How to choose the best peanut oil extraction machine?

- What’s more, the amount of slag taken by the oil press has a direct effect on the quality of the oil. Choosing LONGER peanut oil extraction machine is a very good choice. An advanced oil extraction machine, plus the right press, can produce high quality peanut oil.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What is a peanut oil processing factory?

- The whole peanut oil processing factory includes pretreatment plant, solvent extraction plant and refinery plant. The processing steps of peanut pretreatment and oil pressing workshop: Shelling- separating shells and kernels- cleaning- crushing- flaking- cooking- oil pressing or pre-pressing.

- How is peanut oil extracted by mechanical pressing?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

- Voltage: 220V~380V, adjustable