two shaft sunflower seeds oil extraction plant in lusaka

- Usage: Cooking Oil

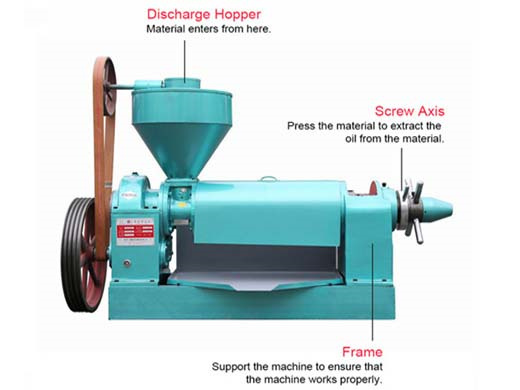

- Type: Oil Extraction Machine

- Production Capacity: 50 TPD

- Voltage: 100 HP

- Dimension(L*W*H): 3505t1820t1981

- Weight: 12000 KG

- Core Components: Motor, Bearing, Gearbox

- Oil type: Sunflower Oil

- Extraction of Oilseeds: Sunflower ,Cotton,Sunflower,Sunflower ,Sunflower Kernel ,Sunflower

- Capacity: 50Ton (24Hours)in pre-pressing & 25 to 30 Ton in Single&Final crushing

- Motor: 100 HP

- Cooking Kettle: Multi Stage

- Bearings: Heavy Duty

- Chamber: Steel Fabricated Chamber

- Body: All Steel Fabrication

- After Warranty Service: Spare parts

- Certification: ISO 9001-2008

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

For today, there are two methods of extracting oil plant raw materials: press and extraction. The advantage of the extraction method is the high degree of oil extraction of 97-98 %, the use

Sunflower Oil Extraction Process, Methods A Full Guide

- Usage: chia seed oil solvent extraction mill

- Type: chia seed oil solvent extraction mill

- Production Capacity: 100%

- Model Number: chia seed oil solvent extraction mill

- Voltage: 220V/380V/440V

- Power(W): 18.5KW/T

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- Certification: ISO9001

- After-sales Service Provided: Overseas service center available

- Keywords: oil press machine

- Name: oil press

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: Chia seed oil solvent extraction mill

- oil rate: 20%-98%

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

When oleic sunflower oil is expressed, a longer reversed pitch screw improves oil extraction yield, which can rise 80% in the optimized operating conditions (Lacaze-Dufaure et al., 1999a). When two reversed pitch screws are used, the oil extraction yield increases with the distance between them and with the decrease of the screw pitch (Amalia.

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Usage: Sunflower Oil

- Type: Cold & Hot Pressing Machine, Sunflower bean oil crushing machine

- Production Capacity: 10TPD-500TPD

- Model Number: 6YY-260

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Certification: ISO9001-2008, CE, BV

- Color: According to customer demand

- Production Material: Carbon steel, stainless steel

- Raw material: Sunflower Seed

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical principle

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

Prepress solvent extraction relies on exerting medium pressure on the prepared seed to separate the majority of the oil, followed by solvent extraction to separate additional oil from the solids fraction, recovering over 40% oil from the seed in modern crushing plants. In a typical sunflower crushing plant using the prepress solvent extraction.

Recent industrials extraction of plants seeds oil used in the

- Usage: Sunflower Oil

- Production Capacity: 100%

- Voltage: 380V

- Power(W): 30kwh

- Dimension(L*W*H): 18M*12M*18m

- Weight: 1 tons

- Certification: ISO9001

- Raw material: Sunflower

The safflower plant is used to produce two types of safflower oil in which the most frequently used oil is an unsaturated oil that accounts for about 75% to 80% of linoleic acid. It contains an enormous amount of unsaturated fatty acid along with less amount of monounsaturated fatty acid which is the major cause to get rancid earlier.

Extraction of oil from crushed sunflower seeds with supercritical CO2 was performed at 280 bar and 40 °C on a laboratory apparatus of 0.15 × 10-3 m3 volume and on a pilot plant of 1.5 × 10-3 m3.

Research on mechanical?structure properties during sunflower

- Usage: SunflowerOil

- Type: Oil Pressing Machine

Automatic Grade: Semi-Automatic - Production Capacity: 100%

- Voltage: 220V/380V

Power(W): 7.5kw - Dimension(L*W*H): 1910*550*765 mm

- Weight: 1200kg

Certification: ISO9001 - Product name: Good quality Sunflowereeds peeling machine on sale

Application: Oil Production Line - Advantage: Energy Saving

- Warranty period: 12 months

Material: Carbon Steel Q235 - Item: Vertical Oil Press

- Feature: Multifunction

Section: Pre Pressing Section - Raw material: Sunflower Seed

- Function: Oil Press + One Drum Filter

The traditional sunflower seed oil extraction method is press ex - traction, which can retain good oil quality and unique flavor (Kartika et al., 2005). It is of great significance to study the mechanical prop-erties of sunflower seeds for oil extraction. So far, many scholars at home and abroad have conducted much research on the mechanical

Oilseed processing and oil extraction processes are designed to obtain high quality oil with minimal undesirable components, achieve high extraction yields and produce high value meal. There are several techniques for extracting oil from oilseeds. Two common oilseed extraction processes are solvent extraction and mechanical extraction using a.

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- How is sunflower oil extracted?

- Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil.

- What is a prepress solvent extraction method in a sunflower crushing plant?

- In a typical sunflower crushing plant using the prepress solvent extraction method, the initial steps of seed pre-cleaning and seed drying are located in the seed receiving section of the facility, prior to seed storage.

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.