sunflower oil direct solvent extraction plant in lagos

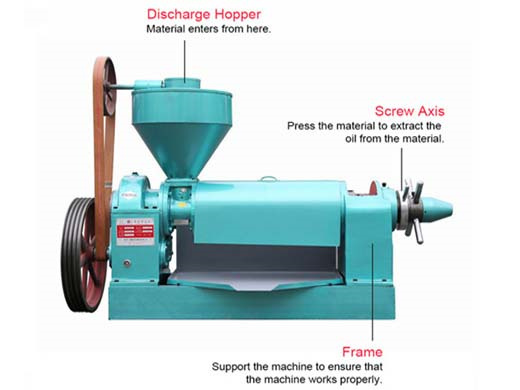

- Usage: Sunflower Oil Press Equipment

- Production Capacity: 98%-100%

- Model Number: 6LD

- Voltage: 380

- Power(W): 5.5KW~15KW

- Dimension(L*W*H): 2200*1600*2150

- Weight: 780kg

- Certification: CE ISO

- Capacity of cold pressed Sunflower oil: 35kg-400kg/h

- Material of cold pressed Sunflower oil: Stainless Steel SS304/316

- Residual oil rate: 5~7%

- Raw material: Sunflower Seed

- Advantage: 36 Years for oil press machine

- Warranty period: 12 months

- Application range: Oil Production Line

- Feature of cold pressed Sunflower oil: High Oil Yield Efficiency

- Function of cold pressed Sunflower oil: Produce High

- Character: Sunflower Oil Press Equipment

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Ultrasound-assisted extraction (power 0.67 W/g oil and 35 C) has been used to greatly improve the direct enrichment of edible oils (sunflower, rapeseed, olive, and soya) with carotenoids from sea buckthorn pomaces in terms of quantity and process time (from

Extraction of sunflower oil using ethanol as solvent

- Usage: Sunflower Oil

- Production Capacity: 5-500 TPD

- Model Number: X1808

- Voltage: 440V

- Weight: 500TONS

- Certification: ISO,CE

- After-sales Service Provided: Engineers available to service machinery overseas

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

Characterization of sunflower oils obtained separately by pressing and subsequent solvent extraction from a new line of seeds rich in

- Usage: Cooking Oil, Sunflower Oil and so on

- Production Capacity: 10--500T/D

- Voltage: 220/380V

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1100kg

- Core Components: Motor, Pressure vessel, Pump, Gear

- Name: Oil press machine

- Raw material: shea kernel

- Application: sunflower oil press

- , Field maintenance and repair service

- Local Service Location: Egypt, Peru, Sri Lanka, Bangladesh, Ukraine, Nigeria, Uzbekistan

- Certification: ISO CE

Oil content (% w/w) extracted from a new line of sunflower seeds rich in phytosterols (IASP-18) and conventional seeds (HA-89) by pressing and subsequent solvent extraction compared to total oil.

Summary. Solvent extraction is the preferred method for the final separation of oil from oleaginous materials containing less than 30% oil by weight. For oleaginous materials with less than 30% oil by weight, such as soybeans, cottonseed, dry process corn germ and rice bran, the material is mechanically and thermally prepared and then sent to.

Efficiency of ethanol and hexane extraction of sunflower oil from seeds of plants inoculated with Azospirillum brasilense and fertilized

- Usage: cotton seed oil

- Type: Cooking Oil Press Machine

- Production Capacity: 6-7Tons/24hrs

- Voltage: 380V/50HZ

- Dimension(L*W*H): 2900*1850*2640mm

- Weight: 4850 KG

- Core Components: Motor, Engine

- Oil type: Sunflower Oil

- price: low, cheap, best, factory price

- quality: high quality, efficient, performance

- application range: Sunflower

- capacity: 10t/d, 20t/d, 30t/d, 40t/d, 50t/d, 60t/d, 70t/d, 80t/d, 100t/d

- section: pretreatment, extraction, refining

- scale: mini, small, large scale

- Oil rate: refining ≥ 97%,

- material: carbon steel & stainless steel

- character: screw oil press, combined oil press

- item: cotton seed oil mill machinery

Oil yield (%) in sunflower seeds cut from plants grown with sludge doses (0; 5,000; 10,000 and 15,000 kg/ha) and two inoculation conditions (with and without inoculation with Azozpirillum.

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

Vegetable Oils as Alternative Solvents for Green Oleo-Extraction, Purification and Formulation of Food and Natural Products - MDPI

- Usage: Sunflower oil processing equipment malaysia

- Type: Sunflower oil processing equipment malaysia

Production Capacity: 10TPH-40TPH - Voltage: 220V/380V

Power(W): According to your Capacity - Dimension(L*W*H): depend on the mode

- Weight: depend on the mode

Certification: ISO9001 - Item: Sunflower oil processing equipment malaysia

After sale service: Yes - Oil extract rate: 21-23%

- Oil content in press cake: 6 %

Oil content in final effluent: 0.6% - Kernel content in cyclone fiber: 0.15%

- Kernel content in dry shell: 2%

Market: Asia, Africa, Southeast Asia - Brand: ;e

Since solvents of petroleum origin are now strictly regulated worldwide, there is a growing demand for using greener, bio-based and renewable solvents for extraction, purification and formulation of natural and food products. The ideal alternative solvents are non-volatile organic compounds (VOCs) that have high dissolving power and flash point, together with low toxicity and less.

Sunflower Seed Preparation and Oil Extraction. is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- Can sunflower oil be used as a substitute for organic solvents?

- Likewise, Li et al. applied sunflower oil as a substitute for organic solvents in carotenoids extraction from fresh carrots using an ultrasound-assisted extraction (UAE) process [ 82 ]. This procedure was compared with conventional solvent extraction (CSE) using hexane as the solvent.

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- How does a sunflower extractor recover the solvent pumped to the extractor?

- The solvent evaporated from the sunflower meal and the miscella are both recovered in the solvent recovery system within the solvent extraction process area. A typical sunflower plant will recover 99.8?99.9% of the solvent pumped to the extractor.

- Voltage: 220V/380V