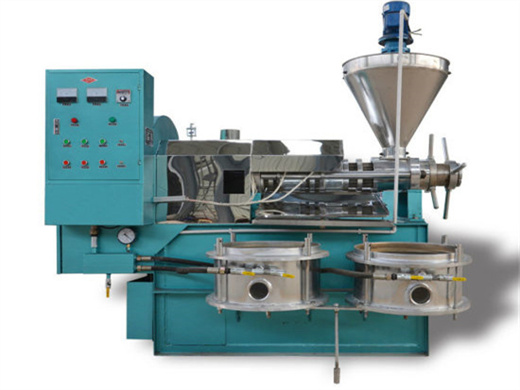

of peanut cake oil extractor machinen in lesotho

- Usage: Peanut Oil, about 150 types oil crops

- Type: Cold Pressing Machine

- Production Capacity: 5-150kg/h

- Voltage: 380v

- Dimension(L*W*H): 420mmx180mmx280mm

- Weight: 140 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other, Motor, Peanut oil processing machine

- Oil type: Peanut Oil

- Raw material: Stainess Steel

- Product name: Oil Press Machine

- Oil Filter power: 1.1kw

- Color: Gray

- Used for1: Peanut

- Used for2: Peanut Peanut bean

- Feature: Eco-Friendly

Foods 2023, 12, 2886 2 of 17 relatively high oleic acid contents [3,4]. The percentage of this monounsaturated fatty acid in regular grains can vary between 41 and 67%, while in grains classi?ed as high-oleic, it can reach 80% [4]. Oil with a high oleic acid content

The defatting ratio is the oil extraction yield, which is the ratio of extracted oil to the total oil that is initially present in peanut seeds before pressing. The mass of extracted oil is the difference between the initial oil content and the residual oil in the cake, which was determined by Soxhlet extraction (as shown in Section 2.6.1 ).

Peanut Oil Processing Technology

- Usage: Peanut etc

- Type: Cooking Oil Processing Machine

- Production Capacity: 2-200T/D

- Model Number: YS Refining

- Voltage: 220V/380V

- Power: Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Certification: ISO9001

- Item: vegetable oil refinery plant

- Material: Alloy steel and cast steel

- Warranty: High quality production, strong structure

- Application: Edible grain and oil production line

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

Ethanol (Et) has been suggested as a substitute for hexane (Hx) for use in the extraction of oils from different oleaginous matrices. In this study, Et and Hx were used to extract the residual oil present in a peanut press cake (PPC). Certain variables, such as temperature, solid/solvent ratio and the number of contact stages, in the sequential cross-current extraction process were evaluated.

Mechanical Methods of Oil Extraction from Peanuts

- Usage: Peanut Oil

- Production Capacity: 20-2000TPD

- Model Number: 011

- Voltage: 380V

- Power(W): standard

- Dimension(L*W*H): standard

- Weight: tandard

- Certification: CE,ISO

- Application: Peanut Oil Production Machine

Peanuts are commonly eaten as a snack or processed into peanut butter, while more than 70% of the harvest is used for oil extraction []. Indeed, peanuts contain between 45.9% and 55.4% of lipids that are specifically high in essential polyunsaturated fatty acids [ 5 ] [ 6 ] [ 7 ] .

Materials Peanuts of commercial variety were procured from the local market in Amritsar (Punjab), India and were stored at 4 C for further treatments and analysis. Methanol, n-hexane, iso-octane, potassium hydroxide and p-anisidine were purchased from Merck (India). 2,2-Diphenyl-1-picrylhydrazyl (DPPH) and 5-hydroxymethylfurfural (HMF) were obtained from Sigma-Aldrich (St. Louis, MO, USA).

Validation of a Simple Extraction Method for Oil Bodies Isolated from Peanuts - ResearchGate

- Condition: New, New, Newest technology

- Usage: Peanut oil refinery ,race bran oil refinery ,Peanut oil refinery

- Type: refined Peanut oil specification

- Production Capacity: 100%, 10TPD-100TPD raw material

- Model Number: 20tons

- Voltage: Local Voltage

- Power(W): 5.5-15.5kw

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 100kg -1200kg

- Certification: CE ISO

- Pressing type: screw oil press

- Oil standard: First class

- Function of refined Peanut wax: refinery oil from crude oil

- power: 20kw/h

- Quality of refined Peanut wax: Superior International

- Residue in cake: less than 6%

- Using of refined Peanut wax: Peanut oil refinery oil plant

- Capacity of refined Peanut wax: 5TPD-1000TPD

subdivided into four equal portions; the ?rst was used to grind the sample using a blender (18000rpm, MJ-60BE01B, Midea) for 2min. The slurry was ?ltered through three layers of cheese cloth.

Oil cakes are produced during oil processing of seeds and categorized in two types i.e. edible and non-edible cakes [5]. Oil cakes have been in use for feed applications to poultry, fish and swine.

Enzyme-Assisted Aqueous Extraction of Peanut Oil - ResearchGate

- Usage: blackseed oil cold pressed machine

- Type: blackseed oil cold pressed machine

Production Capacity: 35-550kg/h - Power(W): 1.5KW

Dimension(L*W*H): 900*850*1550 - Weight: 6-800kg

- Certification: ISO9001

Item: blackseed oil cold pressed machine - Model: 6YY-230 900*850*1550(L,W,H)

Production Handling capacity: 35-550kg/h - Main engine: Y901-4-1.5KW

Electric heating coil temperature: 70-100鈩?/td> PN(MPa): 1000KN - Unit loading weight: 6-800kg

business type: manufacturer - Market: Asia,Africa,Southeast Asia

The optimal conditions were: enzyme concentration of 2.5% (w/w) in 10 g of peanut seeds, pH 4.0, 40°C, and 18 h incubation with constant shaking at 80 rpm. Centrifuging the mixture at 18,000 × g.

The peanut oil solvent extraction plant is one of the most important pieces of equipment in the peanut oil mill plant.Peanut oil solvent extraction plant is ideally suitable to extract and produce oil from any kind of oil cake,such as peanut / groundnut, sesame, copra, linseeds, sunflower, castor seed, cotton seed, palm kernel etc..

- Power(W): 1.5KW