capacity virgin palm oil extractor separator in rwanda

- Usage: Palm Oil

- Type: Palm fruit oil production line

- Production Capacity: 200~2000T/D

- Model Number: PalmOL

- Voltage: 380v/50Hz

- Power(W): up to specification

- Dimension(L*W*H): 1360*950*1170mm

- Weight: up to specification

- Function: Palm fruit oil production line

- Capacity Model: 10T/H,30T/H,45T/H,60T/H,80T/H,100T/H

- Suitable material: Palm oil processing

- Patent product: Yes

- Patent No.: ZL2007 20092291.7;

- Fully automatic: Yes

- Technology: Top technology in China

- Technology support: life time

- Warrenty: one year

- After-sale service: Offering installation and debugging

In Malaysia, the widely used method to extract palm oil from fresh fruit bunches (FFB) is by wet palm oil milling process (Wu et al., 2010). The unit operations used for extractions are a steriliser, a stripper, a digester, a press machine, a clarifier, a separator, an extractor, and a purification system ( Ehsan et al., 2015 ).

Sub-critical extraction of palm oil from palm mesocarp using R134a solvent was conducted via the dynamic mode to investigate the ability of R134a to extract β-carotene. The yield.

Comparasion Study of Sludge Separator and 3 Phase Decanter Performance In Palm Oil Mill (POM)

- Usage: pre-pressing pressing extraction

- Type: Cooking Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 380v

- Dimension(L*W*H): 2.9*1.85*3.24m

- Weight: 5000 KG

- Core Components: Motor, Other, Gear, Bearing, Gearbox

- Oil type: Palm Oil

- Model: 200A-3

- Material: Q235

- Electric: 380v

- Oil residual: 6-8%

- Function: Oil pressing

- HS CODE: 8479200000

- After Warranty Service: Video technical support

The resulting oil loss figures indicate that extracting the oil using a sludge separator or 3-phase decanter is necessary. The research method used in this study is the comparison of primary data and secondary data on the working principle, the number of supporting equipment, electrical power requirements, operations, maintenance, investment costs, and waste quality.

Palm oil is the world’s most-produced vegetable oil that is serving as an important source of food and energy for many developing and underdeveloped countries. The global demand for palm oil will continue to rise, owing to the growing population and economy. Presently, tremendous efforts have been devoted to improving the sustainability of palm oil production. One strategy is to improve the.

Squalene rich virgin palm oil by microwave-assisted enzyme aqueous extraction from palm mesocarp

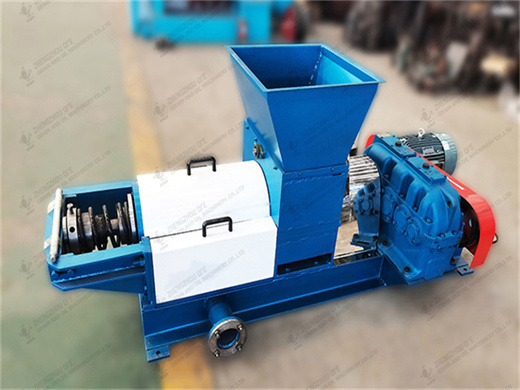

- Model NO.: 6YL series Palm oil expeller/ extraction machine

- Suit for: Vegetable s, Palm

- Big Capacity: 1t-30t/D for Oil Expeller Machine

- Size: 2700*1000*2700mm

- Machine Mainly: Matched with The Whole Oil Press Line

- Machine Installation: We Can Supply It

- Machine Type: Palm Oil Expeller Machine

- Color: Custom Made

- Oil Press Machine Model: 6yl-80, 6yl-95, 6yl-120′6yl-130.Hpyl-180

- Machine Name: Palm Oil Expeller Machine

- MOQ: 1 Set Palm Oil Expeller Machine

- Transport Package: Wood Fuminicated Box

- Specification: National Standard

- HS Code: 84792000

- Production Capacity: 25-30t/D for Oil Press Machine

The palm oil fruit (Tenera spp.) was obtained from a palm oil plantation in Muar, Johor, Malaysia. The chemicals and reagents used in this study such as petroleum ether, hexane, methanol, DNS reagent, glucose, potassium sodium tartrate, sodium hydroxide, and potassium hydroxide were purchased from Merck, Malaysia.

In 2017, the oil palm industry in Malaysia processed about 103.94 million tonnes of FFB into 19.92 million tonnes of CPO and generated 14.55 million tonnes of PPMF with 5?6% of residual oil content, Palm-pressed Mesocarp Oil (PPMO).

palm oil decanter | Alfa Laval

- Usage: Palm Oil

- Production Capacity: 200KG/H Palm oil extraction machine

- Voltage: 380V

- Dimension(L*W*H): 2160*525*780mm

- Weight: 500 KG

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Name: 6YL-95/ZX-10 Palm oil extraction machine

- Applicatio: oil seeds production line

- Capacity: 200KG/H oil press

- Main power: 7.5kw

- Low oil residue in cake: less than 7%

- After-sales Service Provided: Engineers available to service machinery overseas

- Matching machines: roaster,filter machine,conveyor etc

- working manual: we can supply

- Advantage: Energy Saving

- Company type: factory and manufacture

Alfa Laval PANX palm oil decanter centrifuges are designed for oil clarification and purification. The palm oil decanter centrifuge offers maximum oil recovery from sludge underflow or empty fruit bunch liquor with low energy consumption, excellent solid dryness and high-quality separation. The PANX is a proven decanter for the processing of.

The Palm Fruit. The primary feedstock in palm oil mill is the palm fruit. Palm fruit is a drupe, oval in shape, and contains a kernel. The kernel, surrounded by the fruit wall (pericarp), is the true seed. The pericarp is made up of the hard shell (endocarp), oil bearing tissues (mesocarp), and the skin (exocarp).

Design and Development of an Improved Palm Kernel Shelling Machine and Separator - ResearchGate

- Usage: Palm oil machine

- Type: vegetable oil refinery equipment

Production Capacity: 1-100T/D - Voltage: 380V/440v

Power(W): 20-50KW - Dimension(L*W*H): depond on capacity

- Weight: depond on capacity

Main export countries: Asia,Africa,Latin American,Malaysia... Packaging: Glass Container,Plastic Container - Grade: first Grade

- refined oil: 1st grade Palm oil

oil content: 35%-48% - fatty: 40~60.7

- protein: 20~37.2

phosphlipid: 1.25~1.75 - saccharides: 5~15

- Palm oil refining type: Vegetable oil refinery equipment

PDF | On Jan 10, 2017, I Adejugbe and others published Design and Development of an Improved Palm Kernel Shelling Machine and Separator | Find, read and cite all the research you need on.

3.1.4 Digestion of the fruit. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of beater (stirring) arms.

- Why is centrifugal separation a viable method for palm oil extraction?

- The centrifugal technique allowed the separation of mesocarp from the nuts for a better palm oil extraction. Centrifugal separation is viable technique for mesocarp fiber and nuts separation process.

- Why do palm oil extraction techniques suffer from oil loss?

- Current palm oil extraction techniques suffer from oil loss due to the presence of mesocarp fiber and nut during pressing. A digester machine has been developed using centrifugal concept to separate the fiber and kernel eliminating oil loss problem.

- What is the role of a digester in a palm oil mill?

- The role of the digester in a palm oil mill is to macerate the mesocarp from the kernel while also rupturing the oil-carrying cell in preparation for oil extraction. By disintegrating the oil-bearing cell, loosening the mesocarp during digestion enhances oil release.

- What is Alfa Laval Panx centrifuge?

- Alfa Laval PANX-series of decanter centrifuges is designed for palm oil clarification and purification.The units offer maximum oil recovery with low energy consumption. High performance Alfa Laval PANX three-phase decanters are purpose designed for processing crude palm oil.

- Voltage: 380V/440v