100t/d sunflower oil cake solvent extraction plant in ethiopia

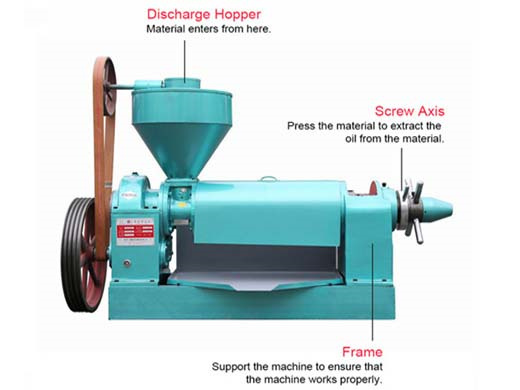

- Usage: Pressing vegetable oils

- Type: Hot Pressing Machine

- Production Capacity: 0.8~1 T/24Hrs

- Voltage: 380V

- Dimension(L*W*H): 920*390*750mm

- Weight: 150 KG

- Core Components: Gear, Bearing

- Oil type: Sunflower Oil

- Color: Green/Blue

- Material: Stainless Steel & Carbon Steel

- Application: Mini edible oil mill plant

- Advantage: Low oil residual mini oil press machine

- Raw material: Sunflower kernel, etc

- Function: Making edible oil

- Energy-driving: Electric motor or diesel engine

- Main market: Zamibia, Ghana, Nigeria, India, Philippine

- Price level: Factory low price screw oil press machine

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Characteristics of solvent extraction: 1. Negative pressure evaporation, high oil yield, high quality oilseed meals; 2. The design capacity of solvent extraction equipment is large, which is beneficial to increase the output and profit, and reduce the cost; 3. The design of solvent extraction system can be adjusted freely according to different.

Extraction of sunflower oil using ethanol as solvent

- Usage: Sunflower oil

- Production Capacity: 35kg-500kg

- Model Number: JXSE

- Voltage: 220V/380V/440V

- Power(W): According to the capacity

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- Certification: CE,BV & ISO9001

- Capacity:

- Production Normal pressure: 1900KN

- Max Operation Pressure: 50MPa

- usage: Easy operate manual mini oil press

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

V.B Oil Mills Private Limited Established in 1989 in India. Our company has started as batch solvent extraction plant of 50 TPD. We started processing sunflower oil cake. We expanded to continuous solvent extraction plant of 150 TPD. We further established another solvent extraction plant of 100 TPD. we also have refinery of 50 TPD capacity.

The Environmental and Social Impact Assessment Report ... - MIGA

- Usage: crude canola oil refinery

- Type: crude canola oil refinery

- Production Capacity: 5T~20T/D

- Model Number: Q-0104

- Voltage: 220V/380V

- Power(W): according to capacity

- Dimension(L*W*H): 5432*2636*2345

- Weight: according to capacity

- Certification: ISO9001

- Item: crude canola oil refinery

- Application: various crude oil like Sunflower Oil

- Operating ways: safe and simple

- Residual oil in cake: low

- Oil grade: high

- Cultivation Type: organic

- Processing Type: refined

- Refining technics: batch refining, semi-continuous refining

- Moisture and volatile: 0.08%

Ethiopia. The proposed Project is for the construction and operation of a Solvent Extraction Plant with a processing rate of 200 Tonnes per day to supply high quality extracted crude oil from oil seeds. These locally available seeds include soyabean, sesame, ground nut, cotton seed and sunflower. It is

Category Edible oils, Mechanical Extraction, Oil refining, Solvent extraction Five trending innovations in the oils and fats processing industry to look for in 2022. Kumar Metal

Expeller Pressed Sunflower Oil vs Solvent Extraction Methods

- Usage: Sunflower oil manufacturers

- Production Capacity: 100% Sunflower oil machine price

- Model Number: Qie

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity, according to the capacity

- Weight: Depand on your capacity

- Certification: CE/BV/ISO9001

- Raw material: Sunflower Seed

- Name: Sunflower oil manufacturers

- Application: Oil Pressing

- Common capacity: 1-1000TPD

- Warranty: One Year

- Character: semi-auto, automatic

- After-sales Service: installation,debugging, training ans service

- Certificate: CE/BV/ISO9001

- Item: Edible Oil Press

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

It is a by-product obtained from the extraction of oil from sunflower seeds. It can be obtained by mechanical pressing resulting in a ?cake“ (see Figure 1) containing 15-20 % oil or by solvent, which increases the quantity of oil. In organic farming, oil may only be extracted by mechanical pressing. The quality of the oil depends on plant.

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Usage: Cooking Oil

- Type: oil filter, vacuum oil filter for edible oil

- Production Capacity: 100TPD

- Voltage: 220/380

- Dimension(L*W*H): depends

- Weight: 100 KG

- Core Components: Other

- Oil type: Sunflower Oil

- Application: Solid-liquid Separation

- Function: Crude oil filter

- Description: Sunflower oil filter press

- Material: Carbon Steel, stainless steel

- Product name: Sunflower oil vacuum filter

- After-sales Service Provided: Online support

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

The most suitable temperature for the growth of sunflower seed is 20 27°C with abundant water. There are several varieties of seeds available consisting of 36% of Oil to 40% of oil based on cultivated area soil condition and species of the seed. The Oil extracted from sunflower seeds either by screw press or by solvent extraction process.