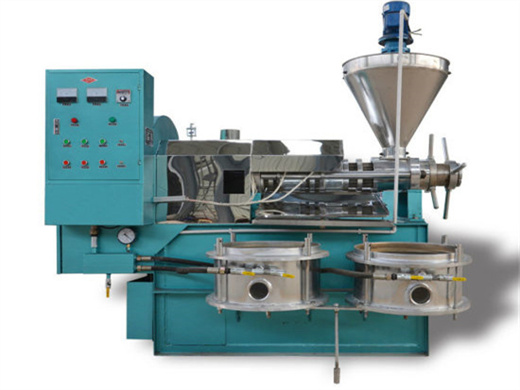

10-50t/d peanut oil extracting machine in johannesburg

- Usage: seeds oil/ vegetable oil

- Type: Cold & Hot Pressing Machine

Production Capacity: 1-1000TPD - Voltage: 220V/380V

Power(W): Standard - Dimension(L*W*H): Standard

- Weight: Standard

Certification: CE ISO - Name: Peanut edible oil refinery , Peanut oil refinery for cooking oil

Raw material: Peanut - Material: Carbon Steel, Stainless Steel

- Warranty: One Year

Advantage: Simple Operation; high oil yield - Color: as require

Henan Glory Company specializes in peanut oil processing machine for 10+ years, customized 1-1000tpd peanut oil extraction machine, offering real-time quotes,great after-sales service. WhatsApp/Tel: 008613526627860 get a free quotation

Fragrant Peanut Oil Production Line. The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical.

Extraction Equipment | Oil Extraction | Distillique

- Usage: edible oil

- Type: Oil Press Machine

- Production Capacity: 100TPD

- Voltage: 220V/380V

- Dimension(L*W*H): depends

- Weight: 30 KG

- Core Components: Other

- Oil type: Peanut Oil

- Raw material: Peanut Oil Expeller Press Spare Parts

- Material: Iron

- Application: Oil press machine

- Function: Making Edible Oil

- Advantage: Energy Saving

- Product name: spare parts oil machine

- key words: Oil press machine spare parts

- Materials: heat treat iron

- Quality: Top Level

- Item: screw, pressing bar, pressing ring, etc

Distillation is followed by Separation in order to separate the Oil from the Hydrosol. Soxhlet Extraction is used to extract the purified Essence (sometimes called The Pure) of a Botanical - it is a more time-consuming process, also with two stages, and it always uses a Solvent to do the Extraction. The actual Soxhlet Extraction is followed by.

1. A wide range of application. It can press more than 20 kinds of oil plant seeds, such as soybean, peanut, sesame, rapeseed, sunflower, olive, palm, peanut and flax seed, etc. 2. High oil yield and purer oil. The equipped vacuum filter is used to remove residue to ensure the pure oil quality and meet the standards of health quarantine.

Peanut Oil Press Machine - Professional Supplier Of Oil Mill

- Usage: Peanut Oil

- Type: Oil Press Machine

- Production Capacity: 5TPD

- Voltage: 220V/110V

- Dimension(L*W*H): 45*18*28CM

- Weight: 12 KG

- Core Components: Others

- Oil type: Peanut Oil

- Name: Mini Oil Press Machine

- Raw material: Peanut, Tung oil seed,Peanut , Peanut kernel

- Function: Oil Pressing

- Application: Peanut

- Material: Stainess Steel mini oil press

- Snail speed: 80 r/min small oil press

- Processing capacity: 3-500 kg/h oil extraction machine price

- Maximum oil output at one time: 1001mL-1500 mL

- Equipped with power: 0.61 kw

- Oil output rate: 98% oil making machine

Flaking Process: After crush and peel,we need to flake the crushed peanut , which make the cell wall of peanut broken . And we flake the peanut to 0.55 mm thickness. Then it is useful for the oil extracting. 4. Cooking Process: After the flaker,we need to cook the flaked peanut , control the moisture at 5-7% , the temperature is 110-115degree . 5.

High oil output rate. The oil yield of a groundnut oil extractor can reach about 50%. The dry cake residue rate is less than or equal to 8%. High efficiency. Our peanut oil expeller can process 500 kg of raw materials per hour. And only one person can operate the machine. Wide range of applications.

Groundnut Oil Manufacturing Process With Flowchart - Hongde

- Usage: Peanut Oil, Cooking Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 10*8*5m

- Weight: 20 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Peanut Oil

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Power consumption: ≤ 15KWh/T

- Solvent consumption: ≤ 2Kg/T (No.6 solvent oil)

- Oil grade: II

- Oil residue ratio: 1%

- Solvent: hexane

- Extraction type: solvent extraction

- Packaging: vacuum packed

- Material: stainless steel

- Color: According to clients

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Peanut oil (groundnut oil, arachis oil), as a kind of light yellow transparent edible oil with clear color and lecture, pleasant fragrance and good taste, is relatively easy to digest. It is not only widely used in China, South and Southeast Asia, it is also popular in the United States. Peanut oil contains more than 80% unsaturated fatty acids.

Peanut Oil Extraction Methods

- Usage: Peanut Oil

- Production Capacity: 92-94%

- Voltage: 380V

- Dimension(L*W*H): 3000*1856*3680mm

- Weight: 5800

- Core Components: Motor, Gearbox

- Name: Oil press

- colour: Optional

- size: 3000*1856*3680mm

- Material: Carbon steel

- Processing capacity: 65-80 tons per day

- Power (KW): 37

- weight: 5800KG

- Dry cake residual oil rate: 14-16%

- After Warranty Service: Video technical support, Online support

- Local Service Location: Egypt, Russia, Kazakhstan, Uzbekistan

- After-sales Service Provided: Video technical support, Online support

The way of steaming, the effect is very good. In addition, when the press is pressed, the setting of the temperature of the oil press is also very important. If it is to make the oil taste strong, the temperature can be a little higher. If it is for the sake of good oil quality, it is recommended that the temperature be set at about 140 degrees.

Advantages of Small Oil Extractor. 1. Simple equipment, low investment, quick returns. 2. Less equipment, low power consumption, small land occupation. 3. The small oil extractor has low solvent consumption. 4. Having strong adaptability, suitable for specialty and high-value oils.

- How to choose the best peanut oil extraction machine?

- What’s more, the amount of slag taken by the oil press has a direct effect on the quality of the oil. Choosing LONGER peanut oil extraction machine is a very good choice. An advanced oil extraction machine, plus the right press, can produce high quality peanut oil.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- What are the best oil extraction machines in India?

- In India’s best oil extraction machines, a big deceleration box is used for more stable cold press oil extraction. The machine has a positive pressure oil filtration system that removes impurities from crude oil particles. 1. Savaliya Industries SL-801 Cold Press Oil Maker Machine

- Voltage: 220V/380V